In the world of custom printing, two popular methods have gained significant attention: heat transfer paper and sublimation printing. Both techniques offer unique advantages and have specific applications in the industry. Understanding the differences between heat transfer paper and sublimation printing is crucial for choosing the right method to achieve the desired results.

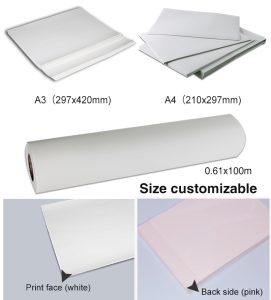

Heat Transfer Paper

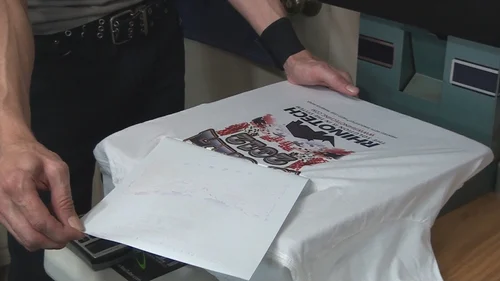

Heat transfer paper, also known as transfer printing paper, is a popular method used to transfer images, designs, or text onto various surfaces using heat and pressure. The process involves printing the desired image onto a special paper using inkjet or laser printers and then applying heat to transfer the image onto the target material. Heat transfer paper works well with fabrics, such as cotton or polyester blends, as well as hard surfaces like ceramics, wood, and metal.

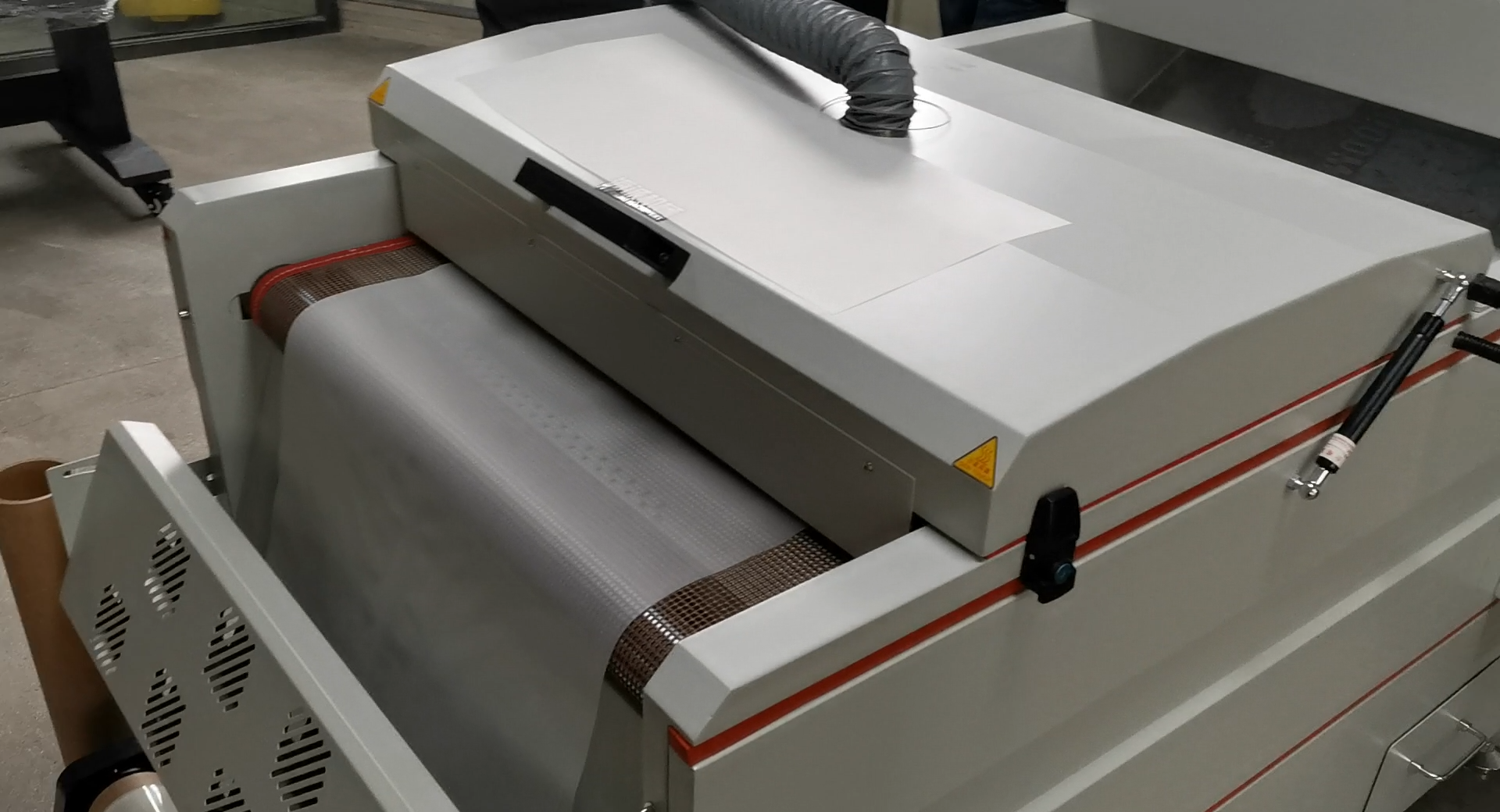

Sublimation Printing

Sublimation printing, on the other hand, is a digital printing technique that uses heat to transfer dye onto materials with a polymer coating. The process relies on the unique properties of sublimation inks, which convert from a solid to a gas under heat and pressure. This gas penetrates the polymer coating of the target material and solidifies, resulting in vibrant and long-lasting prints. Sublimation printing is primarily used on polyester-based materials or items specifically coated for sublimation.

Differences in Image Quality and Durability

One significant difference between heat transfer paper and sublimation printing lies in the image quality and durability of the prints. Heat transfer paper allows for detailed and vibrant prints, particularly on light-colored fabrics. However, the longevity and durability of the prints may vary, depending on factors such as the quality of the transfer paper, ink, and application technique. Over time, heat transfer paper prints may experience fading, cracking, or peeling, especially with frequent washing or exposure to harsh conditions.

On the other hand, sublimation printing offers superior image quality and durability. The dye-sublimation process allows the ink to bond directly with the polymer coating, resulting in prints that are resistant to fading, washing, and general wear and tear. Sublimation prints maintain their vibrant colors and sharpness even after repeated washings, making them ideal for items like sportswear, home décor, and personalized gifts that require long-lasting and high-quality prints.

Versatility and Application Range

Another factor to consider when choosing between heat transfer paper and sublimation printing is versatility and application range. Heat transfer paper provides more flexibility in terms of materials that can be printed. It is suitable for both light and dark-colored fabrics, as well as hard surfaces. However, it is important to note that heat transfer paper works best on materials with a high polyester content, as the ink adheres better to synthetic fibers.

Sublimation printing, on the other hand, is primarily used on polyester-based materials or items with a polymer coating. This limits its application range compared to heat transfer paper. However, sublimation printing excels in producing customized sportswear, promotional items, and vibrant photo prints on polyester fabric. It offers a seamless and professional finish without compromising the breathability or stretchability of the fabric, making it a popular choice in the sports and apparel industry.

Cost Considerations

Cost is an essential factor to consider when choosing between heat transfer paper and sublimation printing. Heat transfer paper is generally more cost-effective compared to sublimation printing. The initial investment for heat transfer paper is relatively lower, as it requires standard inkjet or laser printers and heat presses.