Printable heat transfer vinyl offers numerous advantages that make it a popular choice for customization projects. Firstly, it provides endless design possibilities, allowing individuals to bring their unique ideas to life. Whether it's a family photo, a company logo, or a custom illustration, printable heat transfer vinyl can faithfully reproduce the design with sharp details and vibrant colors. Additionally, it offers the flexibility to print on a wide range of fabrics, including cotton, polyester, blends, and even performance fabrics, ensuring compatibility with various clothing items.

Another significant benefit of printable heat transfer vinyl is its durability. The vinyl is engineered to withstand repeated washes and maintain its vibrant colors without fading or peeling. This durability makes it ideal for creating long-lasting designs on garments that can withstand everyday use.

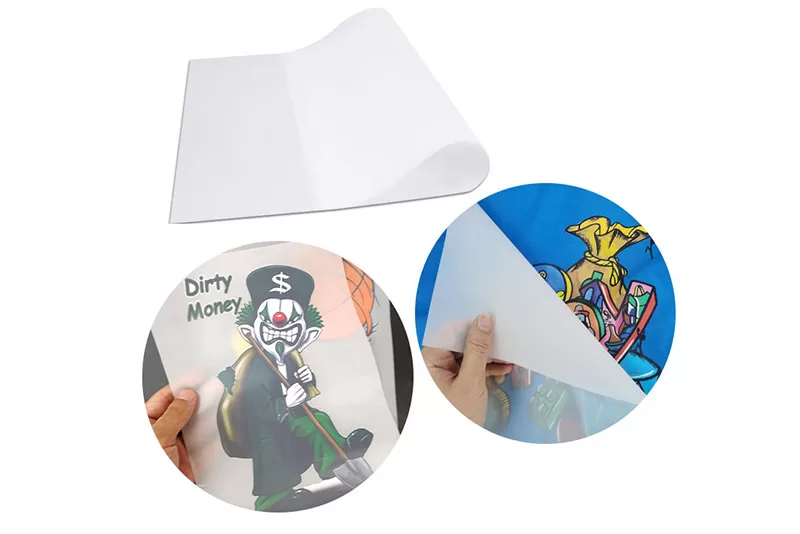

Moreover, printable heat transfer vinyl is relatively easy to use, even for beginners. With a standard inkjet or laser printer, individuals can print their designs directly onto the vinyl, eliminating the need for complex color separations or additional equipment. The vinyl can then be cut using a craft cutter or scissors and applied to the fabric using a heat press or iron.

To better understand the advantages of printable heat transfer vinyl, let's compare it with other commonly used customization methods, such as screen printing and embroidery:

Comparison Table: Printable Heat Transfer Vinyl vs. Screen Printing vs. Embroidery

| Criteria |

Printable Heat Transfer Vinyl |

Screen Printing |

Embroidery |

| Design Complexity |

High |

Moderate to High |

Moderate to High |

|

Color Options

|

Full-color |

Limited (usually up to 6 colors) |

Limited (usually up to 12 colors) |

| Durability |

Excellent |

Excellent |

Excellent

|

| Fabric Compatibility |

Wide range |

Wide range |

Limited (not suitable for delicate fabrics) |

| Cost (for small quantities) |

Moderate |

Moderate |

High

|

| Setup Time |

Quick and easy |

Time-consuming |

Time-consuming

|

| Production Time |

Fast |

Moderate |

Moderate

|

| Texture and Dimension |

Flat and smooth |

Flat |

Textured and raised

|

Note*: The comparison table provides a general overview and may vary depending on specific products and manufacturers.

Section 3: Applications of Printable Heat Transfer Vinyl

Printable heat transfer vinyl finds applications in various industries and creative endeavors. Some common uses include:

Custom Apparel

Printable heat transfer vinyl allows individuals and businesses to create custom t-shirts, hoodies, caps, and other garments with personalized designs. Whether it's a unique graphic, a catchy slogan, or intricate artwork, printable heat transfer vinyl can bring these designs to life on clothing items.

Promotional Items

Companies can use printable heat transfer vinyl to add logos, branding elements, or promotional messages to items like bags, mugs, notebooks, and more. This allows for effective brand promotion and creates customized merchandise that resonates with customers.

Team Sports

Sports teams and organizations can personalize jerseys, uniforms, and accessories with player names, numbers, and team logos using printable heat transfer vinyl. This not only adds a professional touch but also enhances team unity and identification.

Event Merchandise

Printable heat transfer vinyl is widely used for creating merchandise for special events, such as concerts, festivals, trade shows, and conferences. Customized t-shirts, tote bags, or hats can serve as souvenirs and mementos for attendees.

Personalized Gifts

Printable heat transfer vinyl enables the creation of personalized gifts for special occasions. From customized mugs and coasters to monogrammed towels and blankets, the possibilities are endless. These personalized gifts add a thoughtful and unique touch to celebrations, making them even more memorable.

Section 4: Tips for Using Printable Heat Transfer Vinyl

To achieve optimal results with printable heat transfer vinyl, consider the following tips:

Design Preparation

Ensure your design is high-resolution and properly sized for the desired application. Use appropriate design software and consider any color limitations or restrictions imposed by the vinyl manufacturer.

Cutting and Weeding

Use a sharp blade and carefully weed out excess vinyl around the design to ensure clean edges and details. Pay attention to intricate or delicate parts of the design that may require extra care during weeding.

Heat Press Settings

Follow the recommended heat press settings provided by the vinyl manufacturer. Adjust the temperature, pressure, and time according to the fabric and vinyl type being used. Perform a test on a piece of scrap fabric before applying the design to the final garment.

Application Technique

Position the vinyl design on the fabric, ensuring it is centered and aligned correctly. Apply heat and pressure using a heat press or iron, following the manufacturer's instructions. Peel off the backing sheet carefully once the vinyl has cooled down.

Care Instructions

Provide proper care instructions to the end user to ensure the longevity of the design. Advise them to wash the garment inside out, using mild detergent and cold water. Avoid using bleach or fabric softeners that could damage the vinyl.

Printable heat transfer vinyl opens up a world of possibilities for customization, personalization, and creativity. With its ability to reproduce intricate designs, vibrant colors, and durability, it has become a popular choice for individuals, businesses, and organizations looking to add a unique touch to their garments and merchandise. By understanding the versatility and benefits of printable heat transfer vinyl and following best practices, you can unlock endless opportunities to transform ordinary items into extraordinary pieces of wearable art.