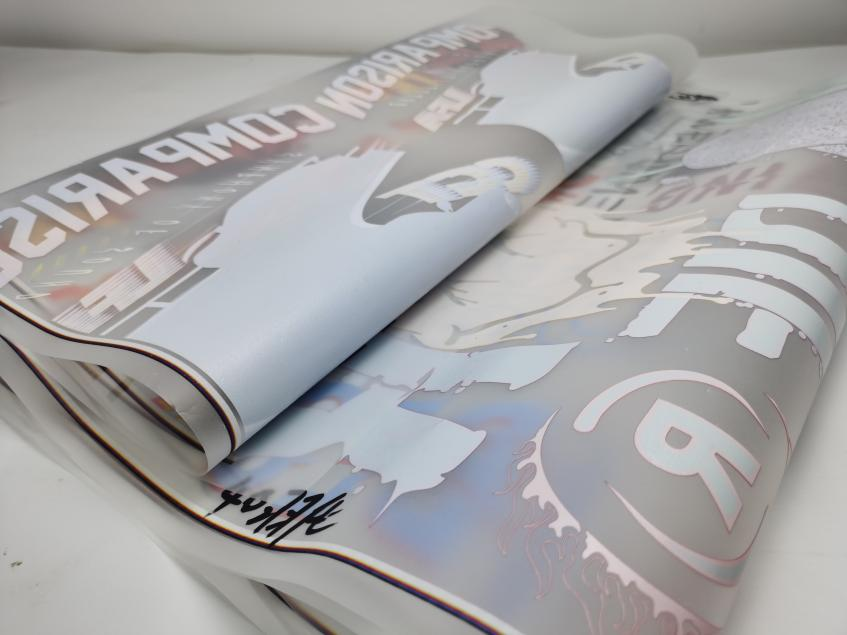

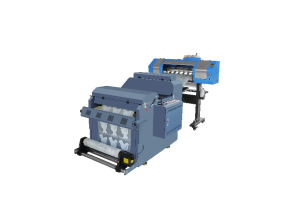

DTF t-shirt printing machine is a brand new garment printing process with specialized inkjet printer ink. It breaks the links of complexity like traditional printing on-demand and makes the process simpler. In addition, DTF printing has photo smoothness, fast delivery, flexible production, and is tailored to individual consumer needs. DTF technology is a completely green and environmentally friendly printing process, which has attracted the attention of the printing industry at home and abroad.

DTF printers have the advantage of environmental protection:

This environmental protection process is not only the function of environmental protection and waste treatment of equipment, but also the consumables that DTF uses are green and environmental protection products. Take this DTF ink as an example. DTF ink is formulated from high quality materials. Thus, the color is not only stable but it can also be restored to its original color.

Pigment inkjet ink has the following advantages:

Variability for different fibers:

Different yarns require different dye inks, while inks are suitable for many different fabrics, especially cotton polyester fabrics.

The process of application is very simple:

Use ink to draw directly on the fabric, inkjet printing. At the same time, there is no need for complicated pre-treatment and post-treatment processes, just print and print directly.

No wastewater discharge, good environmental protection:

Compared with other types otherwise, hot stamping directly on the clothes after DTF printing will not make the color pop. We also do not need to wash with water to remove the floating color like dye ink.

Good color fastness:

After the coating ink is sprayed onto the fabric, it will remain on the fabric in the form tiny seeds. corpuscle. It is hardly degraded by light. Unlike dye ink, this ink is on the fiber. They dyed the molecular fibers. Therefore, most of them also exist in fibers in the molecular state or in relatively loose aggregates. Therefore, it can be easily decomposed under light.

Difference:

The biggest difference between paint ink and dye ink as a colorant is a coloring agent. The color is water-soluble, while the paint is completely water-insoluble.

Summary

Kenteer digital textile inks are suitable for a wide variety of fibers, including single-component fabrics and multi-component blend fabrics. Such as white ink heat transfer printing on cotton, wool, viscose, chemical fiber and blended fabrics. The ink transfer printing process is relatively simple. Easily complete the printing process without pre-treatment or post-washing. So it really realizes the printing without water, and it is also a real environmental protection green ink.