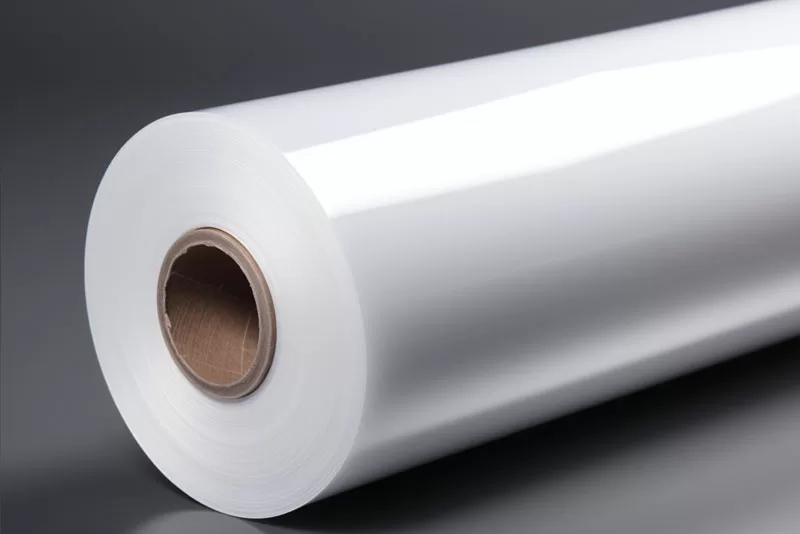

Proper handling and storage of UV DTF PET film is critical to maintaining its quality and optimum performance. Here are some tips to follow:

Treatment of UV DTF PET film:

1. Avoid excessive bending or folding: UV DTF PET film should be handled with care to prevent damage. Avoid excessive bending, folding, or folding of the film as it may cause permanent deformation or damage print quality.

2. Use clean hands or gloves: When handling UV DTF PET film, please ensure that your hands are clean and free of oil, lotion or other contaminants that may be transferred to the film. Alternatively, wear clean, lint-free gloves to minimize the risk of fingerprints or stains on the film surface.

3. Use protective case or packaging: When not in use, store UV DTF PET film in the original packaging or protective case. This helps protect the film from dust, dirt or scratches that can affect print quality.

4. Avoid direct contact with surfaces: prevent direct contact of the film with hard or rough surfaces, avoid scratches or abrasions. Handle the membrane with care and avoid placing on surfaces that may damage the membrane.

Storage of UV DTF PET film:

1. Store in a cool and dry environment: UV DTF PET film should be stored in a cool and dry environment to maintain its quality and performance. Avoid storing film in areas with high humidity or extreme temperature fluctuations, as this can affect its dimensional stability and printability.

2. Anti-ultraviolet: UV DTF PET film should be protected from direct exposure to ultraviolet rays, because long-term exposure will cause degradation and affect its optical properties. Store film in a dark or shaded area away from windows or sources of UV radiation.

3. Avoid heat sources: Keep UV DTF PET film away from heat sources such as radiators, heaters or direct sunlight. Excessive heat can cause the film to deform, warp or lose its dimensional stability.

4. Vertical stacking: When storing multiple rolls of UV DTF PET film, they should be stacked vertically to avoid excessive unwinding pressure. This helps maintain the shape and integrity of the film.

5. Follow the manufacturer's recommendations: For specific storage conditions and shelf life of UV DTF PET films, always refer to the manufacturer's guidelines and recommendations. Different brands or types of film may have specific requirements which should be followed to ensure optimum performance.

By following these handling and storage tips, you can help extend shelf life, maintain quality, and maximize the performance of UV DTF PET films in printing applications.