The global UV DTF film roll wholesale market is expected to grow at a CAGR of 10.5% from 2023 to 2028. The growth of this market is driven by the increasing demand for customized and personalized products, the growing popularity of digital printing, and the rising disposable income of consumers.

UV DTF film roll is a type of digital printing film that uses ultraviolet (UV) light to cure the ink. This makes it a versatile and durable printing solution that can be used on a variety of substrates, including fabric, metal, and plastic.

The increasing demand for customized and personalized products is one of the key drivers of the UV DTF film roll wholesale market. Consumers are increasingly looking for products that reflect their unique style and preferences. UV DTF film roll can be used to print a wide variety of designs, making it a popular choice for businesses that want to offer customized products.

The growing popularity of digital printing is another factor driving the growth of the UV DTF film roll wholesale market. Digital printing is a more efficient and cost-effective printing method than traditional printing methods. This makes it a popular choice for businesses that need to print a large number of products.

The rising disposable income of consumers is also contributing to the growth of the UV DTF film roll wholesale market. Consumers are now more willing to spend money on customized and personalized products. This is creating opportunities for businesses that offer UV DTF film roll printing services.

The global UV DTF film roll wholesale market is segmented by region, application, and type. By region, the market is segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America is the leading market for UV DTF film roll wholesale, followed by Europe and Asia Pacific. The growth of the market in these regions is driven by the factors mentioned above.

By application, the market is segmented into apparel, home décor, gifts & souvenirs, and others. The apparel segment is the largest market for UV DTF film roll wholesale, followed by the home décor segment. The growth of the apparel segment is driven by the increasing demand for customized and personalized clothing.

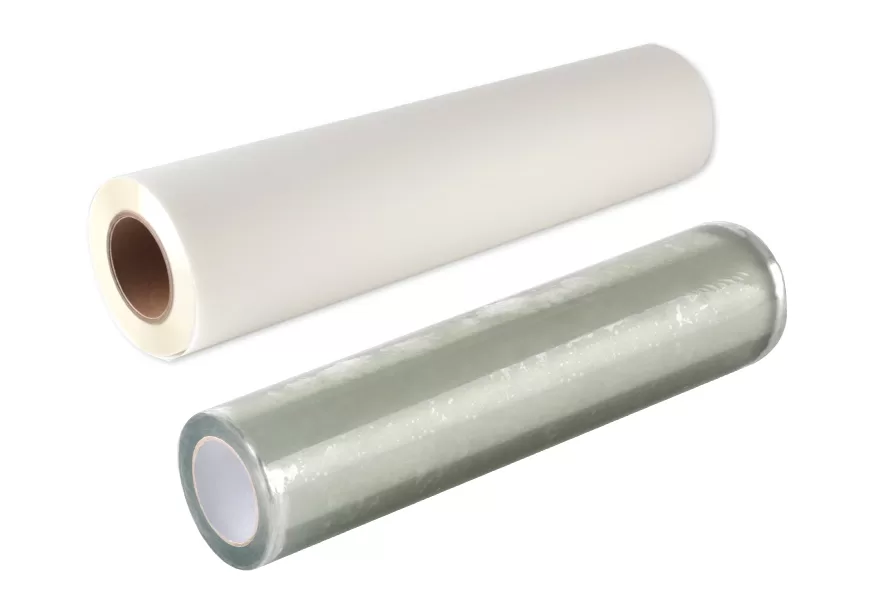

By type, the market is segmented into water-based and solvent-based. The water-based segment is the largest market for UV DTF film roll wholesale, followed by the solvent-based segment. The growth of the water-based segment is driven by the increasing preference for eco-friendly printing solutions.

The key players in the global UV DTF film roll wholesale market include Siser, Printflex, AVP, Mimaki, and Alphatex. These players are focusing on expanding their product portfolio and investing in research and development to stay ahead of the competition.

The UV DTF film roll wholesale market is a promising market with a lot of potential for growth. The factors mentioned above are expected to drive the growth of the market in the coming years.

Investment prospects

The UV DTF film roll wholesale market is a good investment opportunity for businesses that are looking to enter the digital printing industry. The market is growing rapidly and there is a high demand for UV DTF film roll printing services. Businesses that invest in this market can expect to see good returns on their investment.

Here are some of the key factors that make the UV DTF film roll wholesale market a good investment opportunity:

- The market is growing rapidly.

- There is a high demand for UV DTF film roll printing services.

- The technology is relatively new and there is still room for growth.

- The entry barriers are low.

- The margins are good.

If you are considering investing in the UV DTF film roll wholesale market, there are a few things you should keep in mind:

- Choose a reliable supplier.

- Make sure you have a good understanding of the market.

- Invest in marketing and sales activities to reach your target customers.

- Be prepared to invest in research and development to stay ahead of the competition.

The UV DTF film roll wholesale market is a promising market with a lot of potential for growth. If you are looking for a good investment opportunity, this market is worth considering.

Kenteer is a professional coating materials manufacture focus on Prinitng and Cutting solution provider with more than 27 years experience, in China. If you are interested in products, visit website: https://kenteer.com