The KTM-606501A Four-Head Powder Shaker is a high-performance machine designed for high-speed printing of textiles, leather, and other materials. To ensure optimal performance and longevity, it is essential to follow proper maintenance procedures. This article provides comprehensive maintenance guidelines to help you keep your KTM-606501A in pristine condition.

Daily Maintenance:

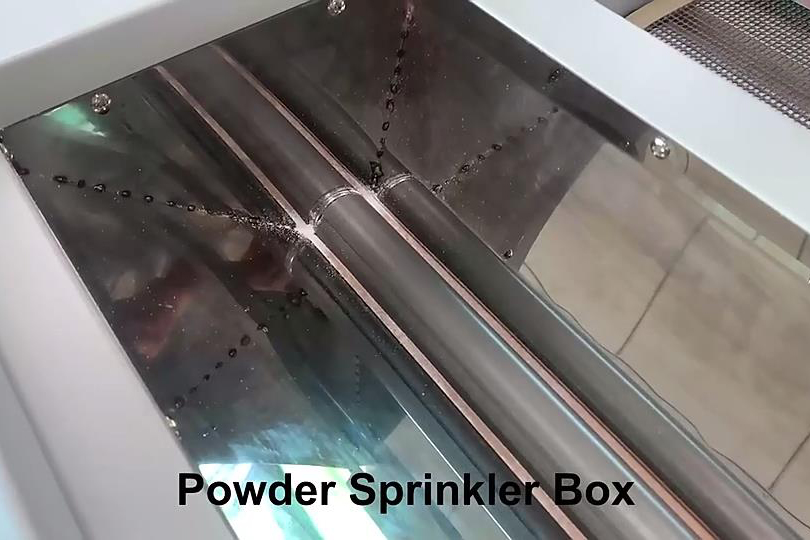

- Clean the powder box: Regularly remove any residual powder from the powder box to prevent clogging and ensure smooth operation.

- Inspect the conveyor belt: Check for any cracks, tears, or debris on the conveyor belt. Clean or replace it if necessary.

- Wipe down exterior surfaces: Use a damp cloth to wipe down the exterior surfaces of the machine to remove dust and debris.

- Check electrical connections: Ensure that all electrical connections are secure and free of corrosion or damage.

Weekly Maintenance:

- Clean the powder sprinkling nozzle: Remove the nozzle and clean any accumulated powder or debris using compressed air or a soft brush.

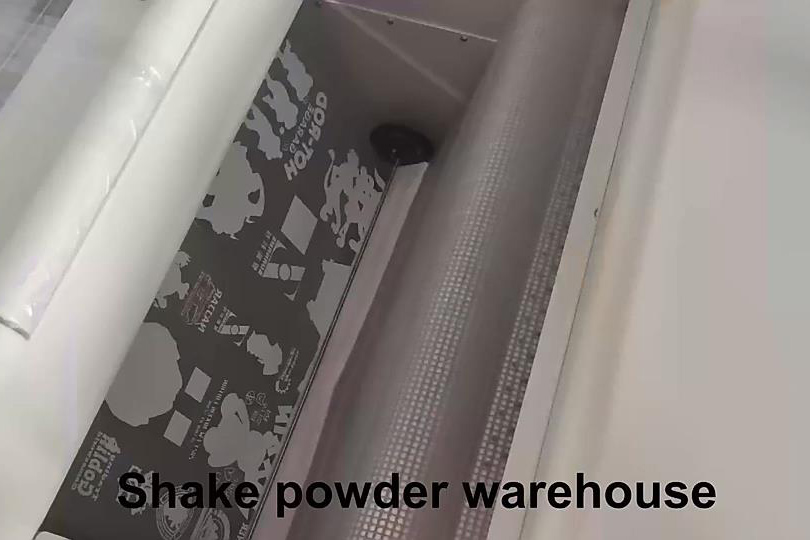

- Inspect the powder spreading mechanism: Check the powder spreading mechanism for any signs of wear or damage. Lubricate and adjust if needed.

- Clean the dust filter (if applicable): If your machine has a dust filter, remove and clean it to remove any accumulated powder.

- Check the temperature probe: Calibrate the temperature probe to ensure accurate readings.

Monthly Maintenance:

- Lubricate moving parts: Lubricate all moving parts, such as bearings, gears, and chains, using a light machine oil.

- Clean the tension rollers: Remove the tension rollers and clean them to remove any accumulated adhesive or debris.

- Inspect the air compressor (if applicable): If your machine has an air compressor, check the air pressure and clean the filters if necessary.

Quarterly Maintenance:

- Replace the powder shaking screen: Replace the powder shaking screen if it shows signs of damage or reduced powder shaking efficiency.

- Inspect the heating and drying system: Check the heating elements, fans, and ductwork for any issues that may affect powder curing.

- Calibrate the powder control system: Calibrate the powder control system to ensure accurate and consistent powder application.

Additional Tips:

- Use high-quality powder: Using high-quality powder will reduce the likelihood of clogging and other issues.

- Store powder properly: Store powder in a cool, dry place to prevent moisture absorption.

- Follow manufacturer's guidelines: Always refer to the manufacturer's guidelines for specific maintenance procedures and intervals.

- Train operators properly: Ensure that operators are trained on proper maintenance techniques to avoid damage to the machine.

By following these maintenance guidelines, you can extend the lifespan of your KTM-606501A Four-Head Powder Shaker and ensure optimal performance and productivity.

If you have product purchasing needs, you can contact us