In the ever-evolving world of screen printing, a revolutionary technology has emerged to transform the way designs are transferred onto various materials. Hot melt adhesive powder has captured the attention of artists, designers, and manufacturers alike due to its versatility, ease of use, and impeccable results. This popular science article will delve into the intriguing world of hot melt adhesive powder, exploring its composition, application process, and the myriad of benefits it offers.

Understanding Hot Melt Adhesive Powder

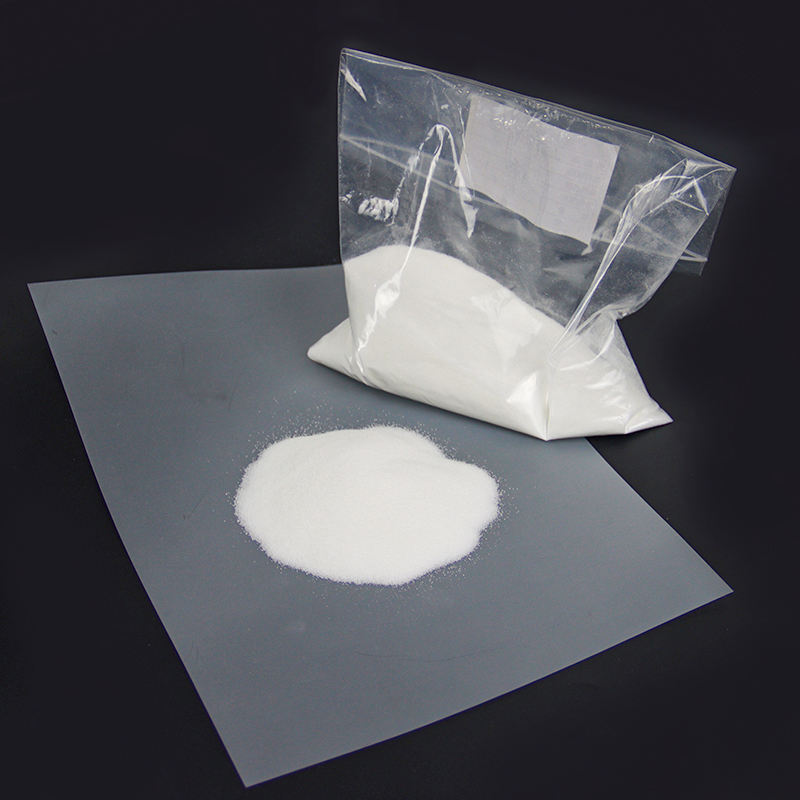

Hot melt adhesive powder, also known as heat transfer powder, is a powdered form of adhesive that is used in the screen printing process. It is composed of thermoplastic polymers that melt and bond when subjected to heat, enabling the transfer of designs onto fabrics, plastics, and other substrates. This unique powder is capable of creating durable, vibrant, and long-lasting prints that resist fading, cracking, and peeling.

The Application Process

The application of hot melt adhesive powder involves a simple yet precise process. Initially, a design is created on a computer and printed onto a special release paper using a standard inkjet printer. This printed design is then placed on top of the substrate, such as a t-shirt or a tote bag, with the adhesive side facing down. Heat and pressure are applied using a heat press machine, causing the adhesive powder to melt and bond with the fabric or material. After cooling and removing the release paper, a vivid and permanent design is left behind.

Versatility and Advantages

One of the most remarkable aspects of hot melt adhesive powder is its versatility. It can be used on a wide range of materials, including cotton, polyester, nylon, and even hard surfaces like ceramics and metals. This adaptability makes it an ideal choice for various industries, including fashion, promotional products, interior design, and crafts.

Moreover, hot melt adhesive powder offers several advantages over traditional screen printing methods. Firstly, it eliminates the need for specialized inks and screens, making the process more cost-effective and time-efficient. Additionally, the absence of solvents and water in the process makes it eco-friendly and reduces waste. The powder itself is non-toxic and safe for use on clothing and other consumer goods.

Furthermore, hot melt adhesive powder provides exceptional color vibrancy and print durability. The adhesive forms a strong bond with the material, ensuring that the design remains intact even after multiple washes. The prints are also resistant to fading, cracking, and peeling, ensuring long-lasting quality.

Limitations and Considerations

While hot melt adhesive powder offers numerous advantages, it is essential to consider its limitations. Due to its reliance on heat and pressure, it may not be suitable for delicate fabrics that cannot withstand high temperatures. Additionally, intricate and highly detailed designs may not be as precise as with other printing techniques.

It is also worth noting that hot melt adhesive powder is not recommended for dark-colored fabrics, as it may result in a loss of color vibrancy. In such cases, pre-treatment with a white under base is necessary to ensure optimal print quality.

Hot melt adhesive powder has revolutionized the world of screen printing, providing artists and manufacturers with an efficient, versatile, and high-quality printing method. Its ease of use, exceptional color vibrancy, and durability make it a popular choice for a variety of applications. Whether it's creating eye-catching apparel, promotional products, or personalized gifts, hot melt adhesive powder opens up endless possibilities for creative expression. Embracing this technology can unleash the true potential of screen printing and elevate designs to new heights.