When selecting hot melt powder, there are several key factors to consider to ensure you choose the right product for your specific application. Here's a buyer's guide outlining those factors:

Bonding Requirements:

- Consider the specific materials you need to bond, such as fabrics, plastics, metals, or foams. Different hot melt powders are formulated to bond different types of materials, so ensure that the powder you choose is compatible with the materials you are working with.

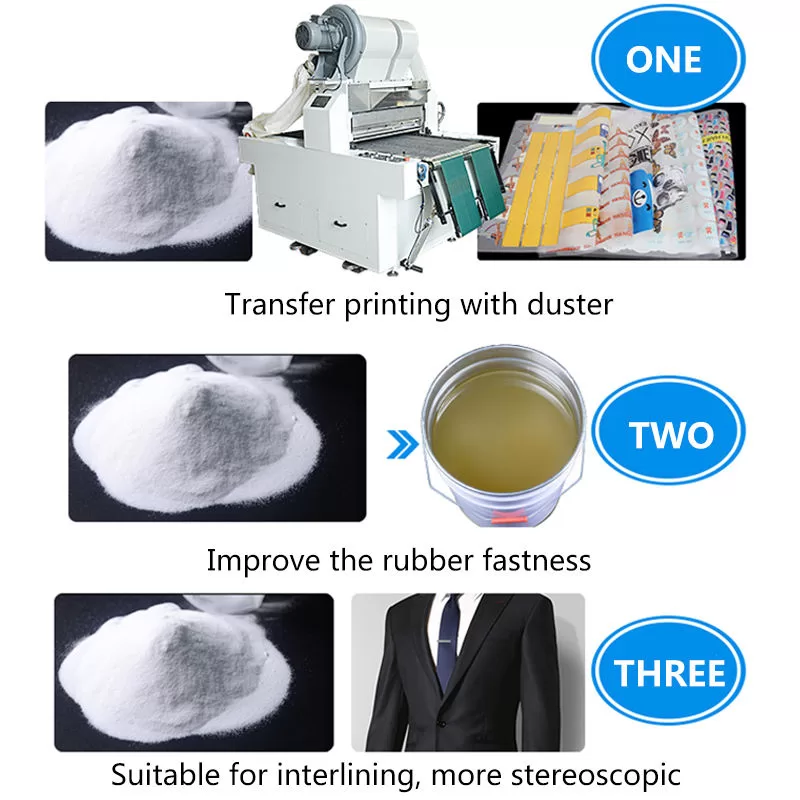

Application Method:

- Determine the application method you will be using, such as a hot press, heat gun, or heat transfer machine. Some powders are designed for specific application methods, so make sure the powder you select is suitable for your chosen method.

Activation Temperature and Time:

- Hot melt powder requires heat to activate and bond. Check the activation temperature and time required for the powder, and ensure that it aligns with the capabilities of your equipment and the materials you are bonding. Different powders have different activation requirements, so choose one that matches your specific needs.

Bond Strength and Durability:

- Evaluate the strength and durability of the bond that the hot melt powder provides. Consider the application's requirements, such as load-bearing capacity, temperature resistance, and environmental conditions, and choose a powder that can meet those demands.

Application Speed and Production Efficiency:

- Consider the speed at which the adhesive powder can be applied and the production efficiency it offers. Some powders melt and bond quickly, allowing for faster assembly and increased productivity. Choose a powder that can keep up with your production demands.

Environmental Considerations:

- Take into account any specific environmental considerations related to your application. For example, if you require a powder with low VOC emissions or if you need a powder that meets specific industry regulations or certifications, ensure that the powder you choose complies with those requirements.

Supplier Support and Technical Assistance:

- Evaluate the support and technical assistance provided by the powder manufacturer or supplier. Consider factors such as availability of product information, technical data sheets, and access to knowledgeable representatives who can help answer any questions or address concerns you may have.

Cost-Effectiveness:

- Consider the cost-effectiveness of the hot melt powder. Compare prices from different suppliers, but also take into account factors such as the efficiency of the powder, its bond strength and durability, and the overall value it provides for your specific application.

Sample Testing and Evaluation:

- Whenever possible, request samples of the adhesive powder to conduct testing and evaluate its performance in your specific application. This will help ensure that the powder meets your requirements and provides the desired results before committing to a larger purchase.

By considering these factors, you can select the most suitable hot melt powder for your application, ensuring strong and durable bonds while optimizing production efficiency and cost-effectiveness.

Kenteer specializes in the production of heat transfer vinyl. If you have production needs, please contact us.