The manufacturing process of transfer tape involves several steps, starting from the sourcing of raw materials to the production of the finished product. Here's an overview of the typical manufacturing process of transfer tape:

1. Raw Material Sourcing: The first step involves sourcing the necessary raw materials for transfer tape production. This includes acquiring the adhesive material, carrier film or liner, release liner, and any additives or coatings required for specific product variations.

2. Adhesive Formulation: The adhesive material is formulated by combining various components such as polymers, tackifiers, and other additives. The formulation is carefully developed to achieve the desired adhesive properties, such as bonding strength, tackiness, and durability.

3. Coating Process: The adhesive is then applied to the carrier film or liner using a coating process. This can be done through various methods, including knife coating, roll coating, or slot die coating. The coating process ensures a uniform and controlled application of the adhesive onto the carrier film or liner.

4. Drying/Curing: After the adhesive is coated onto the carrier film or liner, it goes through a drying or curing process. This allows the adhesive to solidify and develop its full adhesive properties. The drying or curing method can vary depending on the adhesive formulation, and it may involve heat, UV light, moisture, or chemical curing processes.

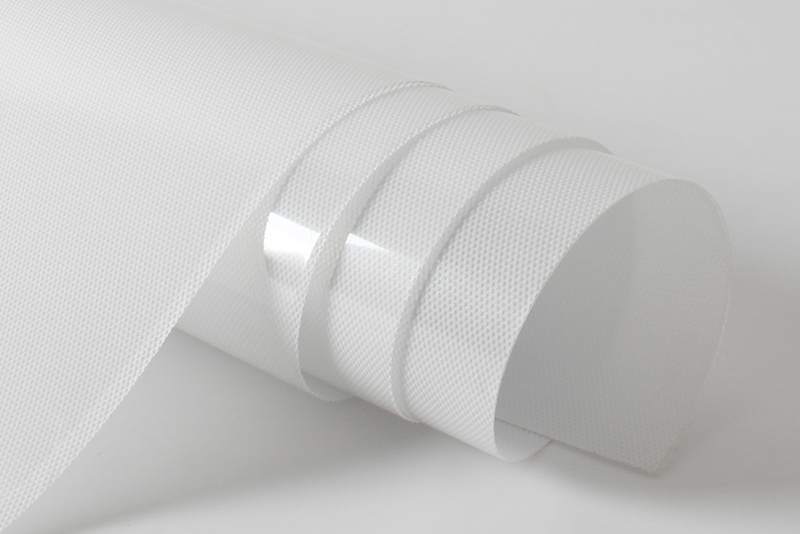

5. Slitting and Die-Cutting: Once the adhesive is fully cured, the coated material is slit into narrower rolls of transfer tape, suitable for various applications. The transfer tape may also go through a die-cutting process, where it is cut into specific shapes or sizes based on customer requirements. This allows for customization and flexibility in the final product.

6. Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure consistent product quality. This involves testing the adhesive properties, thickness, width, and overall performance of the transfer tape. Any defects or inconsistencies are identified and addressed to maintain product integrity.

7. Packaging and Distribution: The final step involves packaging the transfer tape into rolls or sheets suitable for storage and transportation. The rolls or sheets are typically protected with a protective film or packaging material to prevent damage during handling and shipping. The transfer tape is then distributed to customers or stored for future orders.

It's important to note that the manufacturing process may vary depending on the specific requirements of the transfer tape and the manufacturer's production capabilities. However, the overall process typically involves these key steps, from raw material sourcing to the production of the final transfer tape product.

Kenteer is producing transfer tape , please contact us if you need cooperation.