Automotive decor is a significant aspect of vehicle customization, allowing owners to express their personal style and make a statement on the road. Transfer tape, also known as positioning film, plays a crucial role in this process by enabling the transfer of designs onto vehicles. In this article, we will explore the transformative power of transfer tape in automotive decor, showcasing how it can turn ordinary vehicles into personalized masterpieces.

1. Customization Options:

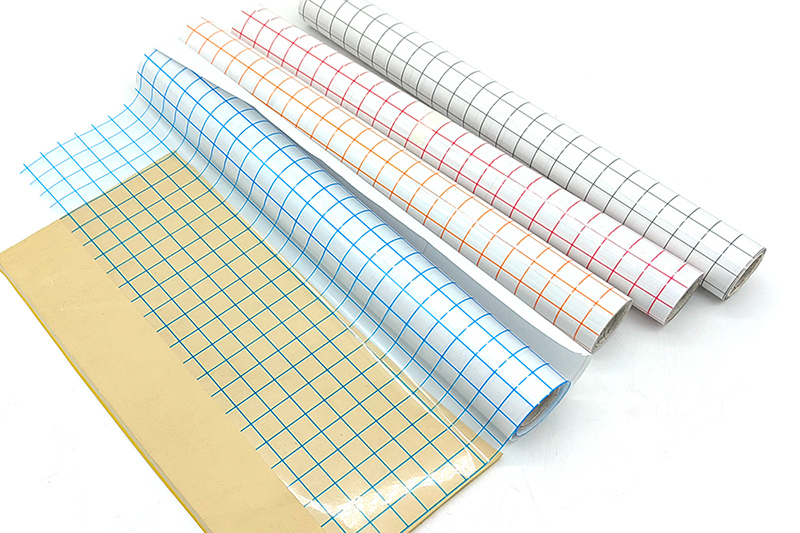

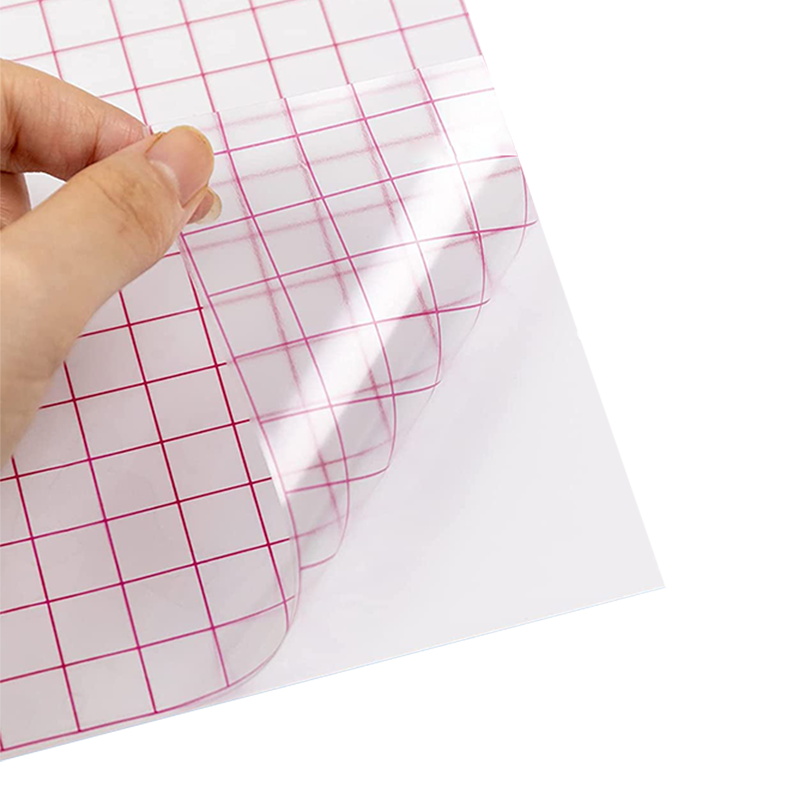

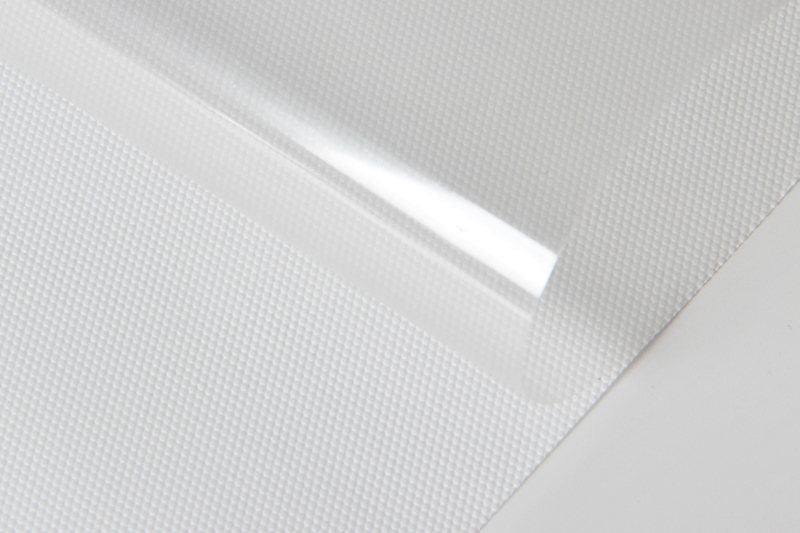

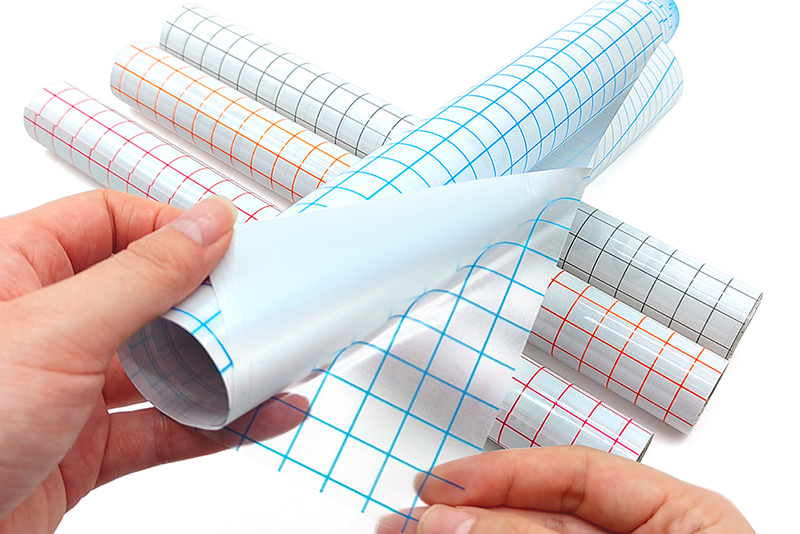

Transfer tape offers a wide range of customization options for vehicles. Whether it's adding stripes, patterns, textures, or graphics, transfer tape allows for endless design possibilities. Its high transparency ensures that the underlying paint color of the vehicle remains visible, creating a seamless integration between the transferred design and the vehicle's surface. With transfer tape, owners can truly make their vehicles unique and stand out from the crowd.

2. Easy Application and Removal:

Transfer tape is designed to be user-friendly, making the application and removal processes hassle-free. It adheres securely to the vehicle's surface, ensuring a long-lasting bond. However, when the time comes for a change or removal, transfer tape can be easily peeled off without causing damage to the vehicle's paintwork. This flexibility allows owners to update their vehicle's decor as often as they desire.

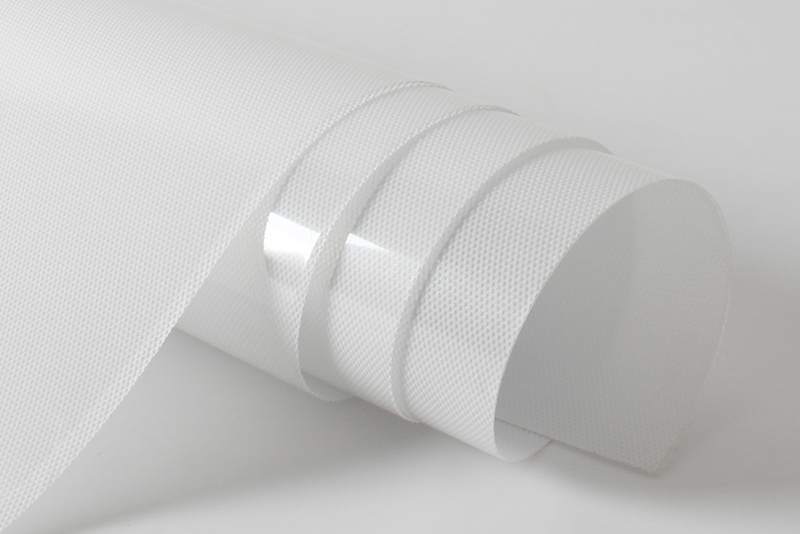

3. Protection and Durability:

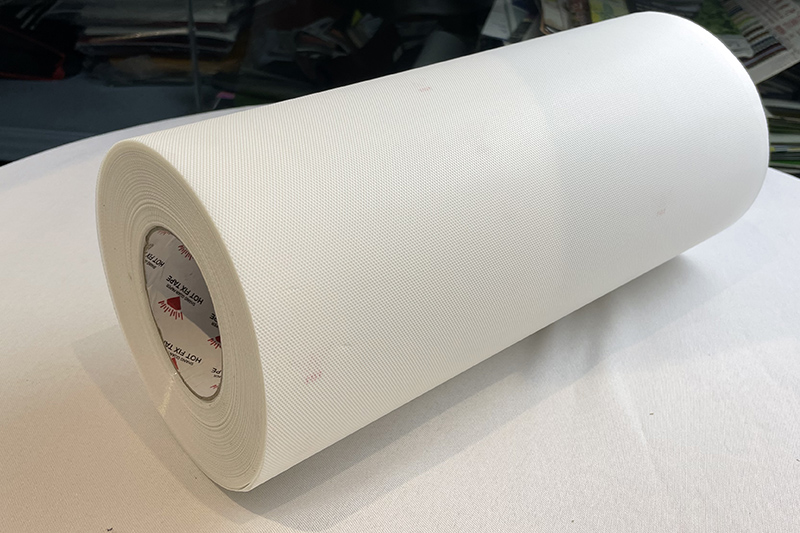

In addition to enhancing aesthetics, transfer tape also provides an added layer of protection to the vehicle's surface. It acts as a shield against minor scratches, abrasions, and UV rays, helping to preserve the original paintwork. The durability of transfer tape ensures that the designs remain intact and vibrant, even in harsh weather conditions. This combination of protection and durability makes transfer tape an excellent choice for automotive decor.

4. Branding and Advertising:

Transfer tape is not only limited to personal vehicle customization but also serves as a powerful tool for branding and advertising purposes. Businesses can utilize transfer tape to display their logos, slogans, and contact information on their fleet vehicles, turning them into moving billboards. This form of mobile advertising allows businesses to reach a wider audience and create brand awareness wherever their vehicles go.

5. Cost-Effective Solution:

Compared to traditional paintwork customization, transfer tape offers a more cost-effective solution. It eliminates the need for expensive and time-consuming paint jobs, making it a budget-friendly option for vehicle owners. Additionally, transfer tape can be easily updated or removed, providing flexibility and cost savings for those who want to change their vehicle's decor over time.

Transfer tape plays a pivotal role in elevating automotive decor, enabling vehicle owners to transform their vehicles into personalized masterpieces. With its customization options, ease of application and removal, protection and durability features, as well as branding and advertising capabilities, transfer tape offers a versatile and cost-effective solution for automotive decor. Whether it's adding stripes, graphics, or branding elements, transfer tape allows owners to express their unique style and make a lasting impression on the road.