Many people don't know what screen printing is, or the names on the market are inconsistent. Today we will talk about the difference between traditional screen printing and heat transfer screen printing.

We see that many customizers use the basic principle that the graphic part of the screen printing plate can pass through the ink, and the non-graphic part of the mesh cannot pass through the ink. When printing, pour ink into one end of the screen printing plate, apply a certain pressure on the ink part on the screen printing plate with a scraper, and move towards the other end of the screen printing plate at a constant speed, and the ink is moved by the scraper from the image and text during the movement. Part of the mesh is extruded onto the substrate. Screen printing is one color and one plate. If it is printed on clothes, it needs repeated color registration to finally make the finished product, and the color registration is limited, so there will be problems of inaccurate color registration, and the gradient effect cannot be done, and the clothes will be scrapped. Screen printing is suitable for large-volume orders with few designs and colors. The screen printing ink is directly attached to the clothes without the feeling of sticking.

Heat transfer printing is also divided into screen printing and offset printing. If screen printing needs to print multiple colors, it needs to print one color at a time. Screen printing printers need to print multiple colors 4 times. Color printing can print several colors at a time. There is also a difference in cost for each color: screen printing requires additional money for one color, while color printing does not require additional money for several colors at a time. The two do not use clothes to print, but print ink on a thermal transfer printing substrates such as release film, and then hot stamp on clothes through a heat press machine. There is no limitation on color registration, and colorful effects such as photos and gradients can be produced. Heat transfer is bonded by hot melt adhesive, which has a sticky feel. Besides we produce different types of screen printing based on different chemicals and printing processes. Different types meet customers’ additional requirements and other fabrics include elastic effect, soft effect, anti-sublimation effect, puff effect, reflective effect, flock effect, silicone effect, care label, etc. What’s more, we produce chemicals for our printing, so that we can control the quality better.

Besides we produce different types of screen printing based on different chemicals and printing processes. Different types meet customers’ additional requirements and other fabrics include elastic effect, soft effect, anti-sublimation effect, puff effect, reflective effect, flock effect, silicone effect, care label, etc. What’s more, we produce chemicals for our printing, so that we can control the quality better. Different types are printed with different chemicals, taking elastic effect heat transfer sticker as an example,First, elastic transparent paste: print once

Different types are printed with different chemicals, taking elastic effect heat transfer sticker as an example,First, elastic transparent paste: print once

Second, elastic white paste: print twice

Third, hot melt glue: print twice

It needs to be dried after each process.

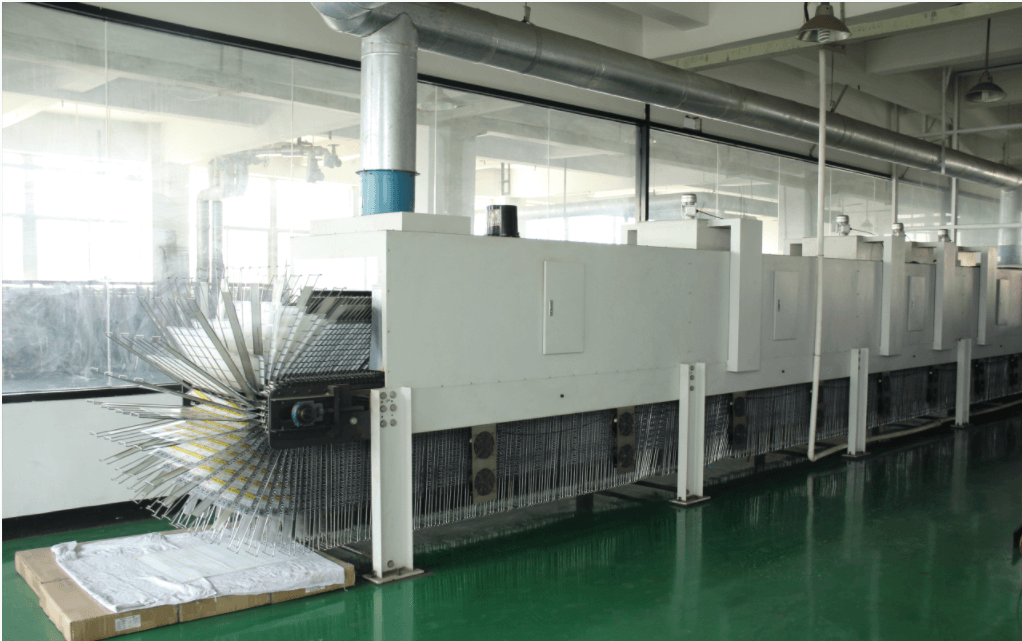

Our drying tunnel is 6 meters long and it stops cylinder type. It is We set the temperature to about 60-70℃. and it will need 15 minutes to take it; for UV infrared type, will need the 20s to 2 minutes.