The Kenteer KTM-A15 UV Printer presents itself as a robust solution for businesses seeking versatile and high-quality printing capabilities. Boasting a dual XP600 printhead configuration and a 600mm print width, this UV printer aims to deliver vibrant and durable prints on a variety of media. This in-depth review will explore the KTM-A15's technical specifications, highlighting its strengths and weaknesses to provide a comprehensive understanding of its potential.

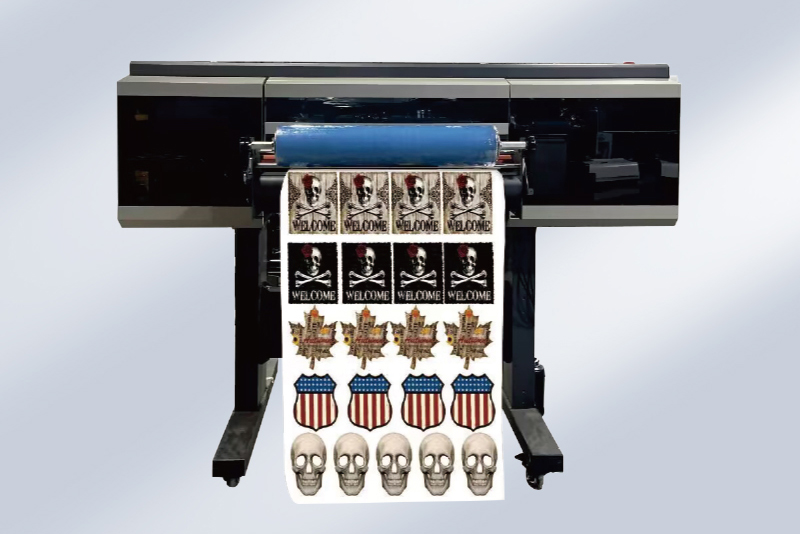

One of the KTM-A15's key strengths lies in its dual XP600 printheads. This configuration allows for faster print speeds compared to single-head UV printers, making it suitable for medium to high-volume production. Kenteer claims print speeds of 4.5㎡/h at 6-pass, 3.1㎡/h at 8-pass, and 1.8㎡/h at 12-pass, catering to various quality and speed requirements. These speeds, coupled with the 600mm print width, position the KTM-A15 as a viable option for printing banners, signage, promotional materials, and more. The inclusion of CMYK+W+V ink configuration expands the color gamut and allows for printing on transparent or colored media, enhancing the printer's versatility. The white ink provides excellent opacity for vibrant prints on dark substrates, while the varnish adds a protective layer and enhances the overall finish, adding value to the final product.

The KTM-A15 UV Printer utilizes UV-curable inks, which offer significant advantages over traditional solvent-based inks. UV inks dry instantly upon exposure to UV light, eliminating the need for drying time and reducing the risk of smudging or bleeding. This instant drying process also allows for printing on a wider range of heat-sensitive materials. Furthermore, UV inks are known for their durability and resistance to fading, scratching, and environmental factors, ensuring long-lasting and vibrant prints. This makes the KTM-A15 a suitable choice for outdoor applications where prints are exposed to the elements.

The printer's resolution options, ranging from 3602400dpi to 7202400dpi, offer a good balance between speed and detail. While not the highest resolution available in the UV printer market, these options are sufficient for most applications, providing crisp and clear prints for text, graphics, and images.

However, the KTM-A15 UV Printer is not without its limitations. One potential drawback is its relatively high power consumption, particularly for the powder dryer (3400W). This could contribute to higher operating costs over time, especially for businesses with high print volumes. The recommended operating environment also requires specific temperature and humidity levels (20-28℃ and 65%-75% relative humidity), which might necessitate additional climate control in some environments, further adding to the operational costs.

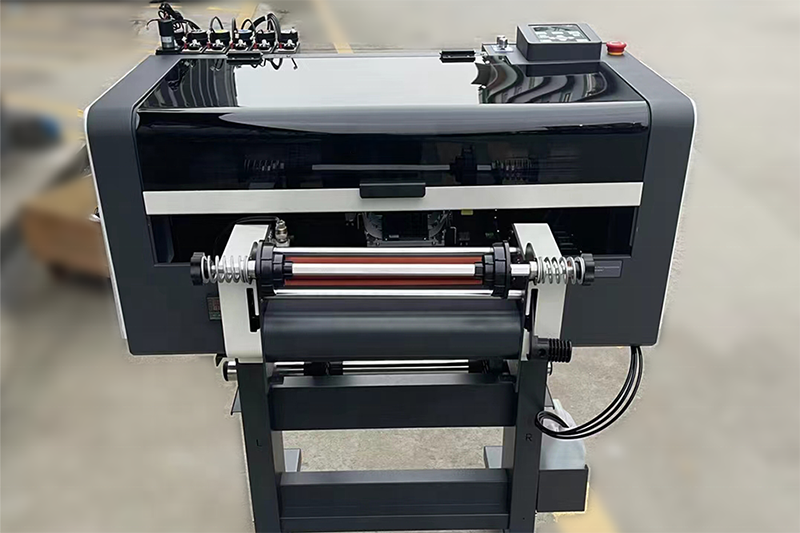

Another aspect to consider is the size and weight of the UV printer. At 168kg and with a footprint of 1380mm x 860mm, the KTM-A15 requires a dedicated space and potentially specialized handling equipment for installation and relocation. While the Maitop 6.1 printing software is offered in both Chinese and English, its usability and feature set compared to other industry-standard RIP software would require further investigation.

In terms of maintenance, the use of UV inks can sometimes lead to printhead clogging if not properly maintained. Regular cleaning and maintenance procedures are essential to ensure optimal performance and longevity of the printheads. The ironing temperature requirement of 160-170℃ for cold/hot peel transfers also necessitates a separate heat press machine, adding to the overall equipment investment.

Overall, the KTM-A15 UV Printer appears to be a capable machine offering a balance of speed, print quality, and versatility. Its dual XP600 printheads, wide color gamut, and UV ink technology make it suitable for a range of applications. However, potential buyers should carefully consider the power consumption, environmental requirements, and overall footprint before making a purchase decision. A thorough evaluation of the Maitop 6.1 software is also recommended. While the KTM-A15 UV printer presents a compelling option in the mid-range UV printer market, a comprehensive cost-benefit analysis, considering both the initial investment and ongoing operational costs, is crucial to determine its suitability for specific business needs. Further research and comparison with other UV Printer models in the same price range are highly recommended.