The KTM-A15 UV Printer represents a significant advancement in digital printing technology, offering a powerful combination of speed, precision, and versatility. This innovative UV printer utilizes ultraviolet (UV) light to cure specialized inks directly onto a variety of substrates, resulting in vibrant, durable, and instantly dry prints. Understanding the underlying mechanics of this process is key to appreciating the capabilities of the KTM-A15.

At the heart of the KTM-A15 lies the printhead assembly, equipped with two XP600 printheads. These printheads are responsible for precisely jetting microscopic droplets of UV-curable ink onto the designated printing surface. The XP600 printheads are known for their high resolution and ability to handle a wide range of ink viscosities, contributing to the KTM-A15's impressive printing accuracy of up to 720*2400dpi. The printer uses a CMYK+W+V ink configuration, providing a broader color gamut and enabling the printing of vibrant colors and opaque white layers, essential for printing on dark or transparent media. The "V" represents varnish, adding a protective layer and enhancing the overall finish of the print.

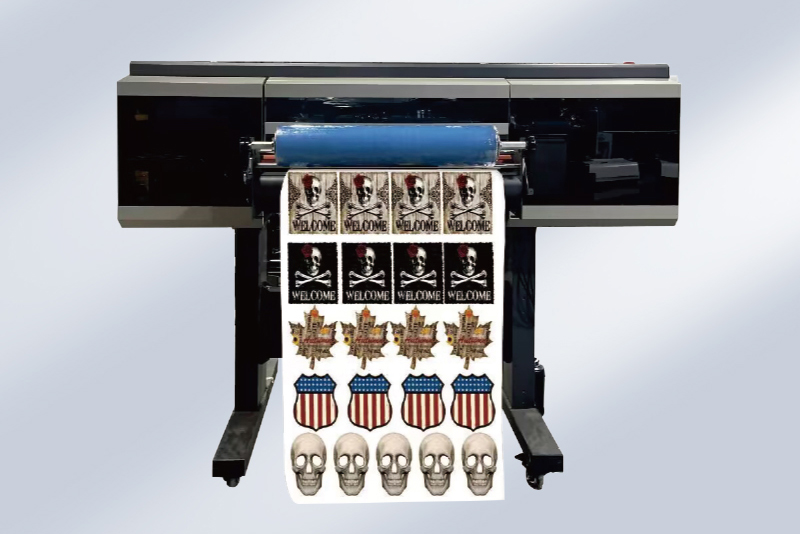

The printing process begins with the Maitop 6.1 software, which acts as the control center for the entire operation. The user inputs the desired design into the software, which then translates it into a series of instructions for the printer. The software controls the movement of the printhead carriage, dictating the precise placement of each ink droplet. The KTM-A15 boasts a maximum printing width of 600mm, allowing for the creation of large format prints suitable for a variety of applications. Print speed is another notable feature, with the KTM-A15 capable of outputting up to 4.5㎡/h in 6-pass mode, offering a balance between speed and quality.

Crucially, the KTM-A15 is a UV printer, meaning that it uses ultraviolet light to cure the ink. As the ink droplets are deposited onto the substrate, they are immediately exposed to intense UV light emitted from strategically positioned lamps within the printer. This UV light initiates a photochemical reaction within the ink, causing it to polymerize and solidify instantly. This rapid curing process is what sets UV printing apart from other printing methods. It eliminates the need for drying time, allowing for immediate handling and finishing of the printed material. Furthermore, the cured ink is highly resistant to fading, scratching, and other environmental factors, contributing to the exceptional durability of UV prints.

The KTM-A15 UV printer is engineered for optimal performance within a specific environmental range. Maintaining a temperature between 20-28℃ and a relative humidity of 65%-75% is crucial for ensuring consistent ink viscosity and proper UV curing. The printer itself requires 350W of power, while the integrated powder dryer consumes 3400W, highlighting the energy requirements of the curing process. The ironing temperature of 160-170℃, along with a cold-hot tear mechanism, further enhances the adhesion and durability of the printed output, especially on textile substrates.

The robust construction of the KTM-A15 UV printer is evident in its 168kg weight and substantial dimensions. This sturdy build ensures stability during operation and contributes to the printer's overall longevity. This UV printer’s features, combined with the precision of the XP600 printheads and the power of UV curing, make it a versatile tool capable of producing high-quality prints on a wide range of materials, including rigid substrates like acrylic, wood, and metal, as well as flexible materials like vinyl and fabric.

From signage and banners to personalized gifts and industrial applications, the KTM-A15 UV Printer opens up a world of possibilities for businesses and creatives alike. This UV printer represents a significant step forward in digital printing technology, offering a compelling combination of speed, quality, and versatility. By understanding the intricate workings of this advanced machine, users can unlock its full potential and produce stunning, durable prints that stand the test of time. This makes the KTM-A15 a strong contender in the competitive landscape of UV printers.