Dye-sublimation transfer paper is a popular choice for creating vibrant, long-lasting prints on a variety of substrates. Knowing the proper techniques and precautions to obtain crisp and detailed prints is very important. In this article, we'll discuss some tips that can help you maximize the potential of your dye-sublimation transfer paper and produce high-quality prints that captivate and impress.

Select high-quality sublimation transfer paper:

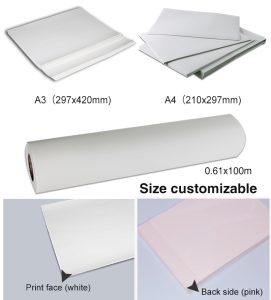

The quality of the dye sublimation transfer paper is crucial to achieving a clear and detailed print. Choose a reputable brand specifically designed for dye-sublimation printing. Look for papers that absorb ink well and have a smooth finish to ensure accurate color expression and sharp image details.

Use high-resolution designs and images:

For crisp, detailed prints, start with high-resolution designs and images. Higher resolutions provide more pixels per inch (PPI) for greater clarity and clarity. Make sure your design file is set to a resolution appropriate for the desired print size. This will help avoid pixelation and ensure sharp image reproduction.

Proper color management: 3. Color management:

Color management is critical to achieving precise and vibrant prints. Calibrate monitors regularly and use color management tools to ensure consistency between design software and dye-sublimation printers. Also, use the ICC profile provided by the sublimation paper manufacturer to ensure accurate color reproduction.

Optimize printing conditions:

Creating an optimal printing environment is very important to achieve clear and detailed printing. Maintain proper humidity in the printing area to avoid ink bleeding or drying too quickly. Make sure your press is properly calibrated and the printheads are cleaned to prevent streaking or streaking.

Test and adjust image settings:

Before printing your final design, do a test print to check for any potential issues or adjustments. This lets you fine-tune settings such as color saturation, contrast, sharpness, and more. Make fine adjustments until you achieve the desired print quality and detail.

Choose the right substrate:

The choice of substrate will affect the final print result. Choose a substrate specifically designed for dye-sublimation printing. These coatings absorb and transfer ink better, resulting in sharper, brighter prints.

Hot pressing technology: 7. Hot pressing technology

Proper heat press technique is essential to obtain clear and detailed prints with dye sublimation transfer paper. Make sure to set the time, temperature and pressure according to the recommendations provided by the sublimation paper manufacturer. Improper heat press settings may result in poor color transfer or incomplete image transfer.

8. Post-processing precautions:

After printing hot press, the printed substrate is cooled completely before handling or further processing. This ensures that the ink and substrate are fully bonded, resulting in sharper, more durable prints.

By following these tips, you can improve print quality and detail when using dye sublimation transfer paper. Please remember to choose high-quality paper, optimize printing conditions, and pay attention to color management. Test and adjust as needed to select the proper substrate for best results. With proper heat pressing techniques and post-processing precautions, sharp and detailed prints can be obtained that leave a long-lasting impression.