The KTM-B05 Powder Shaker is a versatile and efficient machine designed to automate the powder shaking process in the production of PP paper and PET hot stamping film. With its advanced features and customizable settings, it streamlines the powder spreading and curing process, ensuring consistent and high-quality results.

Comprehensive Control Panel

The KTM-B05 Powder Shaker features a comprehensive control panel that provides precise control over all operational parameters. The automatic and manual control modes allow for flexible operation, while the powder shaking speed, powder spreading time, mesh belt suction speed, mesh belt speed, and mesh belt direction can be finely adjusted to suit specific material properties and process requirements. Additionally, the curing temperature, leading heating plate temperature, and cooling fan control enable precise temperature management for optimal curing results.

Efficient Heating and Drying System

The KTM-B05 Powder Shaker employs a highly efficient heating and drying system to ensure proper curing of the powder coating. The leading heating plate provides focused heating to initiate the curing process, while the drying and curing zone utilizes hot air to evenly distribute heat throughout the material. The cooling fan control allows for precise temperature regulation during the cooling stage, preventing overcuring and ensuring the desired surface finish.

Automated Material Conveyance

The KTM-B05 Powder Shaker utilizes a mesh belt conveyor system for material transport. The adjustable mesh belt speed and suction speed ensure optimal adherence of the powder to the material surface. The automatic sensing rolling function detects the presence of material and automatically initiates the rolling process, eliminating the need for manual intervention.

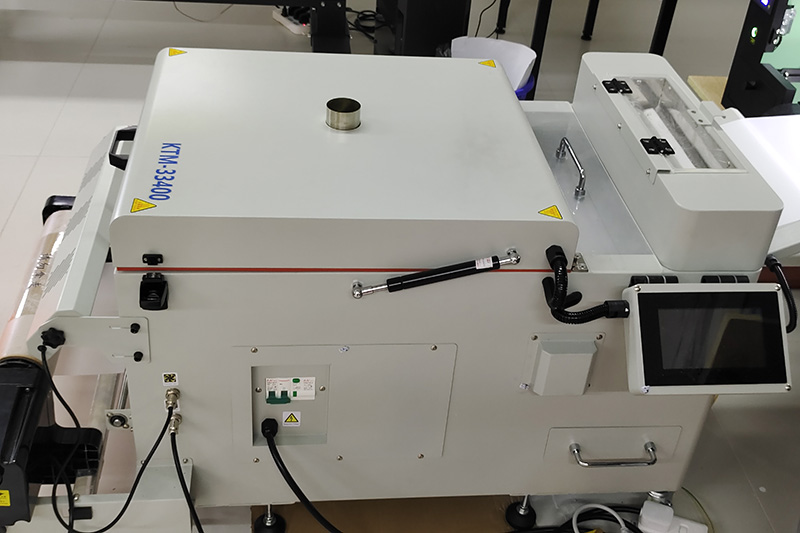

Compact and Portable Design

The KTM-B05 Powder Shaker is designed for compact and portable installation. Its dimensions and low weight make it suitable for integration into existing production lines or for use in smaller-scale operations. The machine is easy to transport and can be quickly set up, reducing downtime during relocation.

Technical Specifications

- Machine Model: KTM-B05 POWDER SHAKER

- Winding and Unwinding Medium Width: 0-600mm

- Applicable Medium: PP Paper/PET Hot Stamping Film

- Control Panel: Automatic/Manual control, Powder shaking speed control, Powder spreading time control, Mesh belt suction speed control, Mesh belt speed control, Mesh belt direction control, Curing temperature control, Leading heating plate temperature control, Cooling fan control

- Heating and Drying Function: Leading heating plate heating, Drying and curing, Cooling with cold air

- Material Conveyance: Mesh belt conveyance, Belt-guided

- Rolling Function: Automatic sensing rolling

- Electrical Parameters: Rated voltage 220V, Rated current 16A, Power 6.5KW

- Heating and Drying Box Size: 1200mm

- Packing Size and Weight:

Machine: L2760W1100H1070MM

Packaging: L2070W115H1130MM

GW: 300KG

The KTM-B05 Powder Shaker combines advanced technology, comprehensive control, and efficient material handling to provide a superior powder shaking solution for PP paper and PET hot stamping film production. Its versatility, ease of use, and compact design make it an ideal choice for both large-scale operations and smaller-scale applications. With its precise control over operational parameters and reliable performance, the KTM-B05 Powder Shaker elevates quality standards and streamlines production processes, contributing to increased efficiency and profitability.