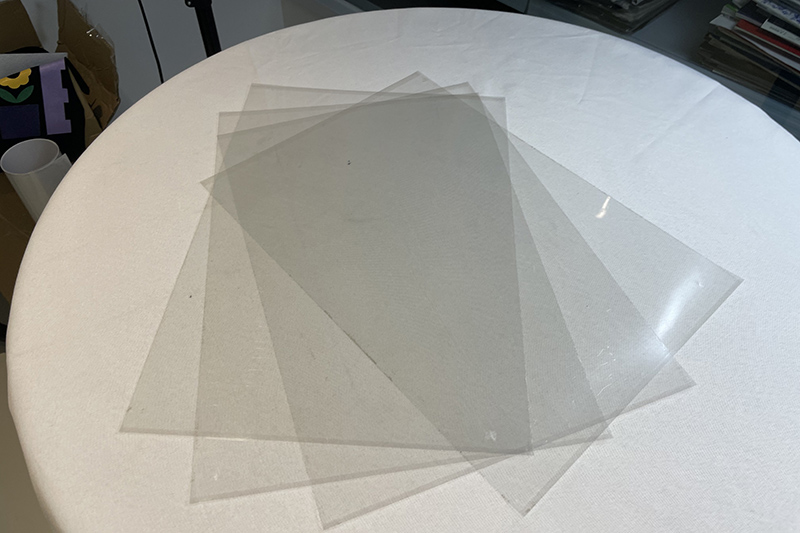

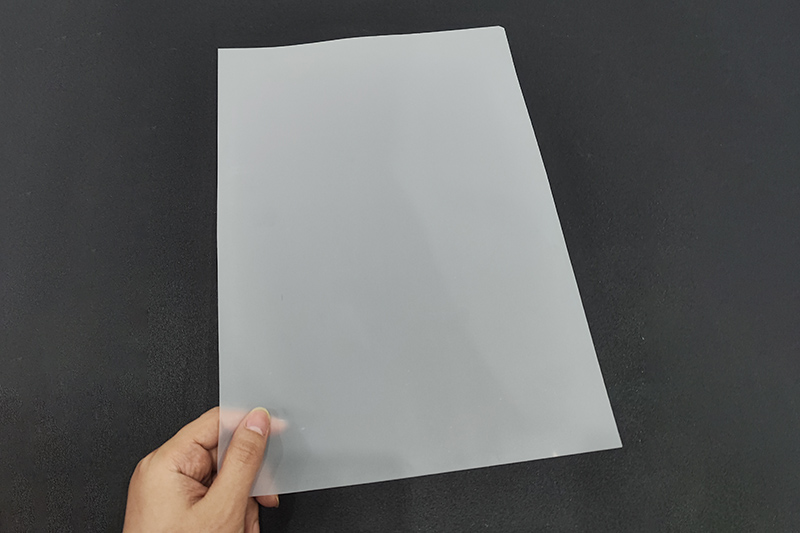

When comparing the performance of three-layer and four-layer DTF films, several factors come into play. Here's a breakdown of the key performance aspects to consider:

1. Print Quality: Both three-layer and four-layer DTF films can produce high-quality prints, but the number of layers can impact the level of detail and color vibrancy. Four-layer films typically offer better color saturation and image sharpness due to the additional layers. However, the difference in print quality may vary based on the specific brands and formulations of the films.

2. Washability and Durability: The number of layers in DTF films can affect their washability and durability. Four-layer films generally provide better resistance to washing, fading, and peeling due to the added layers of protection. This can result in longer-lasting prints, especially for applications that require frequent washing or exposure to harsh conditions.

3. Stretch and Flexibility: DTF films need to be able to stretch and conform to the contours of the garment or substrate during application. Both three-layer and four-layer films can offer good stretch and flexibility, allowing for comfortable wear and durability. However, four-layer films might have a slight advantage in terms of conformability due to the additional layers.

4. Breathability: The breathability of the film is essential, especially for garments. Three-layer DTF films typically have better breathability compared to four-layer films, as the additional layer in four-layer films can slightly reduce air circulation. This can be a factor to consider for applications where breathability is crucial, such as sportswear or activewear.

5. Production Efficiency: Three-layer DTF films generally require fewer steps and less time for the printing process compared to four-layer films. This increased efficiency can be advantageous, especially for high-volume production or tight deadlines. Four-layer films may require additional steps for layering and curing, which can impact production time and efficiency.

6. Cost: The cost of the films is an important consideration. Three-layer DTF films typically cost less than four-layer films due to the difference in material usage. However, it's important to consider the overall value and performance of the film rather than just the initial cost.

It's important to note that the performance of DTF films can vary between brands and formulations. It's recommended to test different films and consult with suppliers to evaluate their specific performance characteristics based on your application and requirements.

Kenteer is a professional coating materials manufacture focus on Prinitng,Our main products contain DTF films,welcomes consultation and cooperation.