Hot melt powder, also known as hot melt adhesive powder, has become increasingly popular in the printing industry for its versatility and strong bonding properties. Whether you're looking for hot melt powder for heat transfer printing, screen printing, or direct-to-film (DTF) applications, understanding its uses and benefits is essential. In this article, we will delve into the world of hot melt powder, including its applications, advantages, and key considerations when selecting the right product for your printing needs.

Understanding Hot Melt Powder

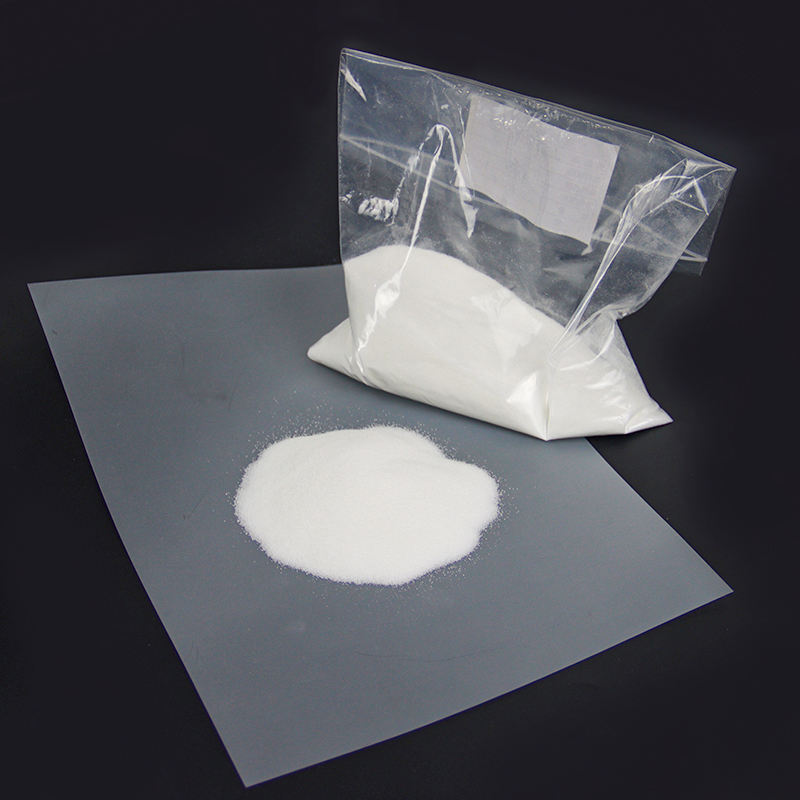

Hot melt powder is a dry adhesive substance that is activated by heat to create a strong bond between substrates. It is typically composed of a thermoplastic polymer and other additives to enhance its adhesive properties.

Applications of Hot Melt Powder

Heat Transfer Printing: Hot melt powder is commonly used in heat transfer printing processes to create vibrant and durable designs on various textiles and fabrics.

Screen Printing: It is also used in screen printing to achieve precise and detailed prints on different substrates.

Direct-to-Film (DTF) Printing: Hot melt powder plays a vital role in DTF printing, where it acts as an adhesive layer to transfer designs onto films for subsequent application onto garments or other surfaces.

Advantages of Hot Melt Powder

Strong Bonding: Hot melt powder offers excellent adhesion, creating a strong bond between different substrates. It ensures long-lasting and durable prints, even in demanding conditions.

Versatility: Hot melt powder can be used on various materials, including fabrics, textiles, papers, and films. It provides flexibility in terms of application methods and compatibility with different printing techniques.

Easy Activation: The activation of hot melt powder requires heat, which can be achieved through heat presses, ovens, or other suitable equipment. It ensures quick and efficient bonding, saving time in the printing process.

Key Considerations for Hot Melt Powder Selection

Application Compatibility: Different hot melt powders are designed for specific printing applications, such as heat transfer printing, screen printing, or DTF printing.

Ensure that the hot melt powder you choose is suitable for your intended application to achieve optimal results.

Substrate Compatibility: Consider the types of substrates you will be working with, such as fabrics, textiles, or films. Choose a hot melt powder that is compatible with the specific substrates you will be printing on.

Activation Temperature: Hot melt powders have different activation temperature ranges. It is essential to select a powder that activates within the desired temperature range for your printing equipment and materials.

Adhesive Strength: Assess the adhesive strength required for your printing application. Different hot melt powders offer varying degrees of bonding strength, so choose accordingly to ensure the durability of your prints.

Popular Hot Melt Powder Varieties

Hot Melt Powder for Heat Transfer Printing: This type of hot melt powder is specifically formulated for heat transfer printing applications, ensuring excellent adhesion and durability on textiles and fabrics.

Hot Melt Adhesive Powder for Screen Printing: Designed for screen printing, this hot melt powder allows for precise and detailed prints on a wide range of substrates.

DTF Hot Melt Powder: DTF printing requires a specialized hot melt powder that acts as an adhesive layer to transfer designs onto films for subsequent application.

TPU Hot Melt Powder: TPU (Thermoplastic Polyurethane) hot melt powder is a versatile option known for its excellent flexibility, elasticity, and resistance to abrasion.

It is commonly used in applications that require high-performance bonding, such as footwear, textiles, and automotive industries.

Hot Melt Adhesive Powder for Heat Transfer: This type of hot melt powder is specifically formulated for heat transfer applications, ensuring excellent adhesion and durability on a wide range of materials, including fabrics, garments, and promotional items.

Hot Melt Glue Powder: Hot melt glue powder is a general-purpose adhesive that offers strong bonding properties across various substrates.It can be used in both industrial and crafting applications.

Choosing a Reliable Hot Melt Powder Supplier:

Quality and Performance: Look for suppliers known for providing high-quality hot melt powders that meet industry standards.

Consider factors such as adhesive strength, bonding durability, and compatibility with different substrates.

Application Expertise: Select a supplier with expertise in the specific printing application you require, whether it's heat transfer printing, screen printing, or DTF printing.

They can offer valuable insights, recommendations, and technical support to ensure optimal results.

Product Range and Customization: Choose a supplier that offers a diverse range of hot melt powder options to cater to various applications and substrates.

Customization options, such as different activation temperatures or adhesive strengths, can also be advantageous for specific printing needs.

Consistent Supply and Timely Delivery: Consider suppliers with a reliable supply chain to ensure consistent availability of hot melt powder.

Timely delivery is essential to avoid production delays and meet project deadlines.

Customer Reviews and Support: Read customer reviews and testimonials to gauge the reputation and reliability of the supplier.

Assess their level of customer support, including responsiveness to inquiries, technical assistance, and issue resolution.

Hot melt powder, with its strong bonding properties and versatility, has become an integral part of various printing applications, including heat transfer printing, screen printing, and DTF printing. By understanding the different types of hot melt powder available and considering factors such as application compatibility, substrate compatibility, activation temperature, and adhesive strength, you can make an informed choice when selecting the right hot melt powder for your printing needs.