Heat transfer printing has revolutionized the way we personalize and decorate textiles, garments, and various other products. A key component of this printing method lies in the selection of suitable heat transfer printing materials. From heat transfer vinyl to DTF printing film and PET release film, understanding the features and applications of these materials is crucial for achieving vibrant, durable, and high-quality results. In this article, we will delve into the world of heat transfer printing materials, guiding you in choosing the right solution for your specific projects.

Heat Transfer Vinyl (HTV):

Heat transfer vinyl, often referred to as HTV, is a popular choice for customizing fabrics. It consists of a vinyl material with a heat-activated adhesive backing. Key features and benefits include:

a) Versatility: HTV can be applied to a wide range of fabrics, including cotton, polyester, blends, and even specialty materials like leather and nylon. Its versatility makes it suitable for various applications, from apparel and accessories to home textiles and promotional items.

b) Easy Application: HTV is easy to cut and weed, allowing for precise and intricate designs. It can be applied using a heat press machine or a household iron, providing convenience for both professional and DIY enthusiasts.

c) Durability: When applied correctly, HTV offers excellent durability, withstanding repeated washing and wear without fading or cracking. It ensures long-lasting and vibrant designs that maintain their original quality.

DTF Printing Film:

DTF printing film, short for Direct-to-Film, is a newer innovation in heat transfer printing. It involves printing designs onto a specialized film, which is then transferred to the fabric. Key features and benefits include:

a) Enhanced Detail and Color Reproduction: DTF printing film allows for high-resolution, detailed designs with vibrant colors. It offers a broader color gamut and finer details compared to traditional heat transfer methods, resulting in stunning and visually striking prints.

b) Versatility in Substrates: DTF printing film is compatible with a wide range of fabrics, including cotton, polyester, blends, and even dark-colored textiles. This versatility expands the possibilities for customization across various product categories.

c) Soft and Breathable Results: DTF prints offer a soft and breathable feel, ensuring comfort when applied to garments. The prints seamlessly integrate with the fabric, providing a natural look and minimizing the presence of a "plastic" texture.

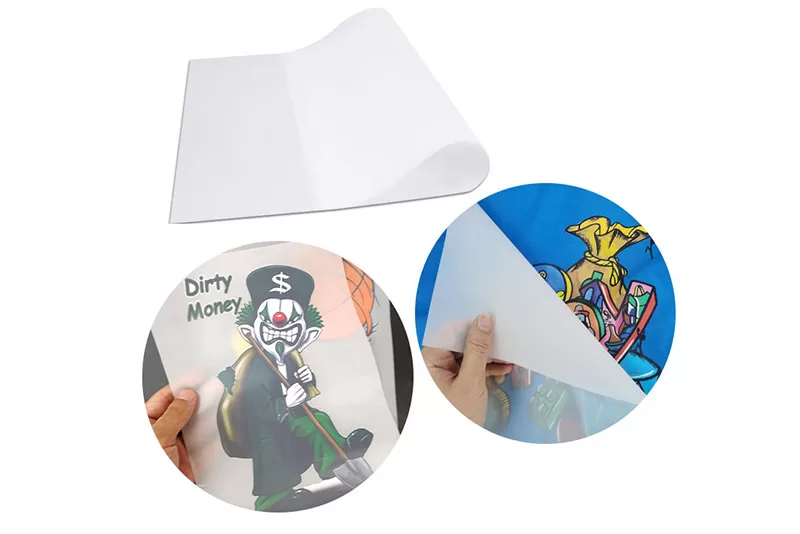

PET release film, or release liner, plays a vital role in heat transfer printing by acting as a carrier for the heat transfer materials. Key features and benefits include:

a) Easy Application and Removal: PET release film allows for smooth and hassle-free application of heat transfer materials onto the fabric. Its non-stick surface ensures clean and easy removal, preserving the integrity of the transferred design.

b) Excellent Release Properties: PET release film provides optimal release properties, enabling precise and accurate transfers. It ensures that the heat transfer materials adhere to the fabric effectively, resulting in sharp and well-defined prints.

c) Compatibility and Adaptability: PET release film is compatible with various heat transfer materials, including HTV and DTF printing film. It can accommodate different printing techniques, making it a versatile choice for heat transfer printing applications.

Conclusion:

Selecting the right heat transfer printing materials is crucial for achieving outstanding results in your customization projects. Whether you opt for the versatility and convenience of heat transfer vinyl (HTV), the enhanced detail and vibrant colors of DTF printing film, or the reliable carrier functionality of PET release film, understanding the features, benefits, and applications of these materials is essential. By making informed choices and exploring the possibilities of heat transfer printing materials, you can unleash your creativity, elevate your products