In the world of adhesive technologies, hot melt powder has emerged as a powerful and versatile solution for various industries and applications. This innovative adhesive material offers unique advantages and opens up new possibilities for bonding different substrates. In this article, we will introduce you to the fascinating world of hot melt powder, exploring its properties, applications, and the benefits it brings to the manufacturing and product assembly processes.

What is Hot Melt Powder?

Hot melt powder, also known as thermoplastic powder or hot melt adhesive powder, is a solid material that transforms into a liquid adhesive when heated. It is typically composed of polymers, resins, and additives that provide the desired adhesive properties. Hot melt powder is available in various forms, such as granules, flakes, or powders, depending on the application requirements.

Properties and Advantages of Hot Melt Powder:

a) Versatile Bonding: Hot melt powder offers exceptional versatility in bonding a wide range of materials, including textiles, fabrics, foams, papers, films, wood, plastics, and metals. Its ability to create strong, durable bonds across different substrates makes it a valuable choice for various industries, including textiles, automotive, electronics, packaging, and more.

b) Heat Activation: The activation of hot melt powder occurs through the application of heat, usually achieved through hot air, infrared, or induction methods. This activation process allows for precise and controlled bonding, ensuring efficient assembly and minimizing production time.

c) Bond Strength and Flexibility: Hot melt powder provides excellent bond strength, creating durable and reliable connections. Additionally, it offers flexibility, allowing the bonded materials to maintain their desired properties without compromising performance.

d) Environmental Friendliness: Hot melt powder is a solvent-free adhesive solution, making it environmentally friendly compared to solvent-based alternatives. It eliminates the need for harmful chemicals and reduces emissions during the bonding process.

Applications of Hot Melt Powder:

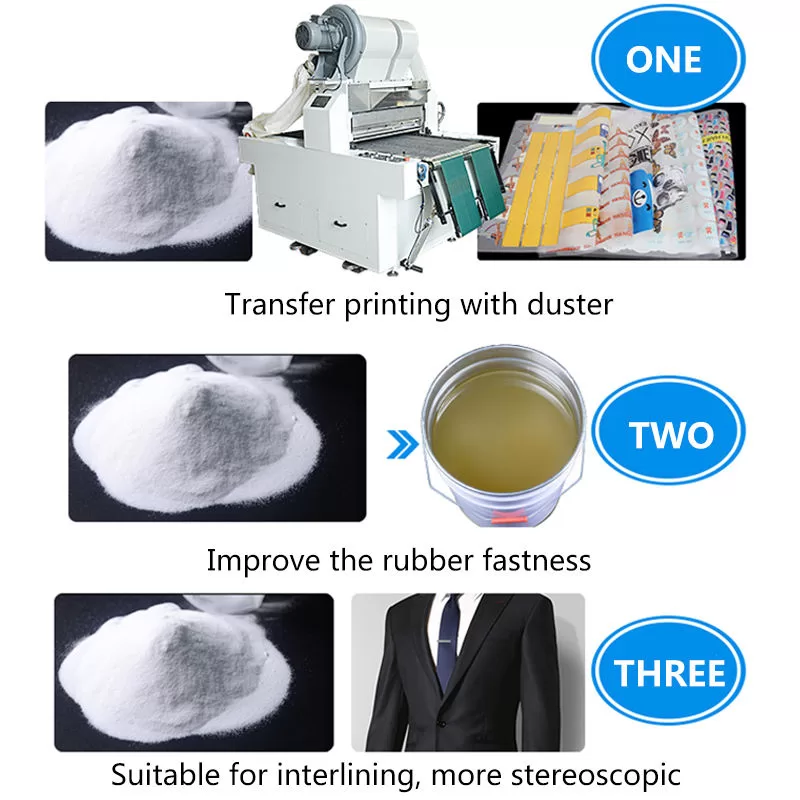

a) Textile and Apparel Industry: Hot melt powder finds extensive use in textile and apparel manufacturing processes. It is employed for seam sealing, bonding fabrics, attaching labels, embroidery backings, and creating laminated textiles, offering enhanced durability and performance.

b) Packaging and Product Assembly: Hot melt powder is widely utilized in packaging applications for carton sealing, case and tray forming, and box assembly. Its quick-setting nature enables efficient production lines and secure package sealing.

c) Automotive Industry: Hot melt powder plays a crucial role in automotive interior assembly, such as bonding headliners, door panels, carpets, and foam components. It ensures strong adhesion and enhances the overall structural integrity of the vehicle interior.

d) Electronics and Electrical Appliances: Hot melt powder is used for bonding electronic components, wire harnesses, connectors, and insulation materials. Its excellent electrical insulation properties ensure reliable connections and protect against moisture and environmental factors.

Conclusion:

Hot melt powder represents an exciting advancement in adhesive technology, offering versatility, efficiency, and durability in bonding various materials across different industries. Its heat activation, strong bond strength, and environmental friendliness make it an ideal choice for applications in textiles, packaging, automotive, electronics, and more. By harnessing the power of hot melt powder, manufacturers can achieve improved production processes, enhanced product quality, and increased efficiency, thereby unlocking new possibilities for innovation and growth.