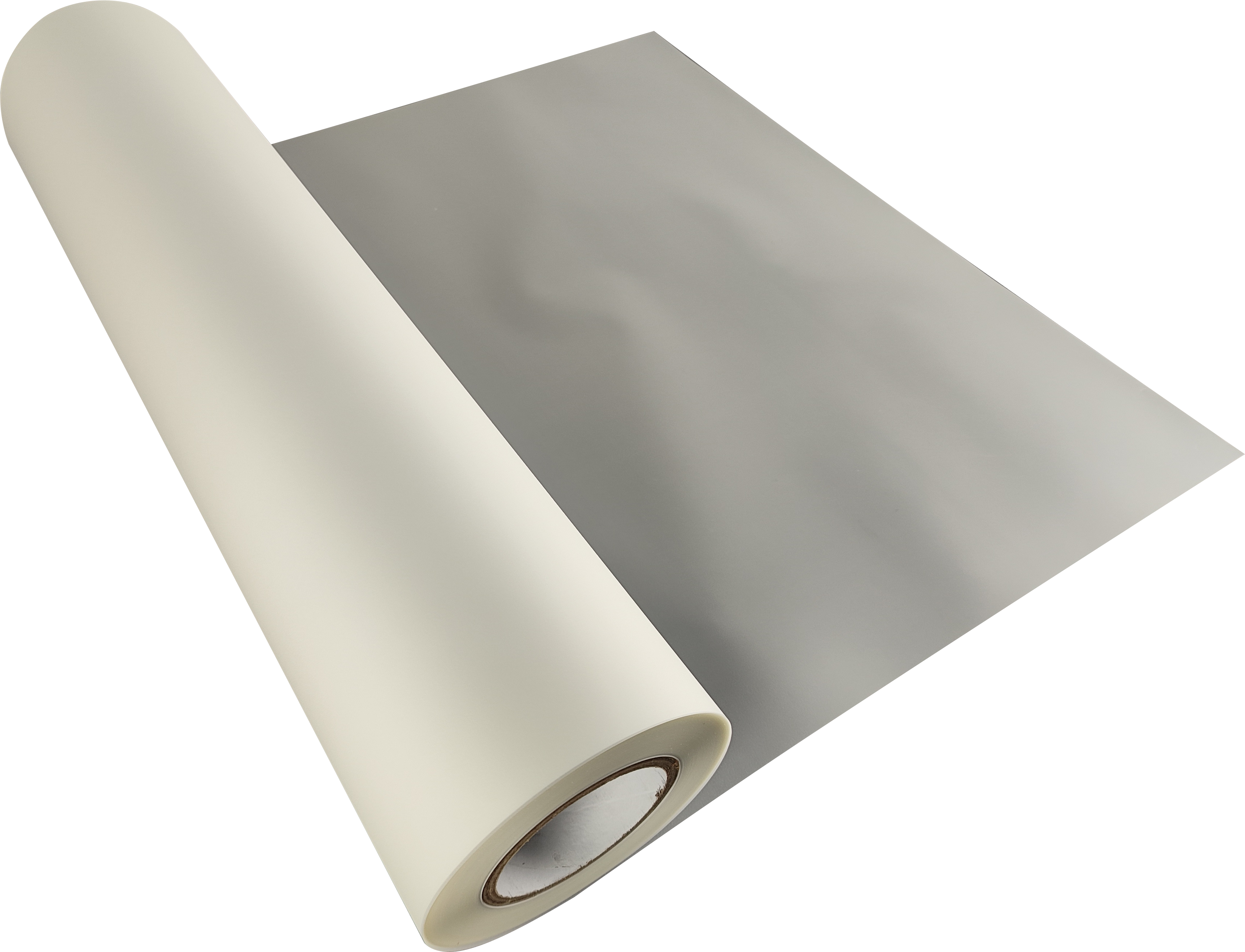

Kenteer DTF PET film quality standards include the following aspects:

1. Transparency: the printing film needs to have a certain transparency to ensure that the printing effect is clear and the color is bright.

2 Thickness and flatness: the thickness of the printing film should be uniform, and the surface should be flat, with no defects such as bubbles or dents.

3. Heat resistance: the printing film needs to have good heat resistance to ensure that it will not deform, melt or produce harmful substances in high-temperature environment.

4. Water resistance: printing film needs to have good water resistance to ensure that it will not be damaged in a wet environment.

5. Viscosity: Printing film needs to have appropriate viscosity, in order to stick to different surfaces, and maintain long-term stability.

6. Light resistance: The printing film needs to have good light resistance to ensure that it will not fade or deteriorate under sunlight or ultraviolet irradiation.

7. Safety performance: the printing film needs to meet the relevant national standards and not contain harmful substances to ensure the safety of the human body and the environment.

DTF film and ink matching performance?

1. Printing effect: DTF film should have a good printing effect, the image is clear and vivid, full and true color, no color bias, broken ink, and other phenomena.

2. Durability: DTF film should have strong light resistance, water resistance, wear resistance and other properties, to ensure that the printing effect can be maintained for a long time.

3. Melting point: DTF film should have a low melting point, can adapt to different types of printers and print head requirements.

4 Adaptability: DTF film adaptability is stronger, can adapt to the requirements of different pigments and ink, to avoid ink and printing film mismatch caused by color difference or quality problems.

For the matching performance of printing film and ink, the key is to ensure that the formula and performance of the two match each other, to ensure the consistency and stability of the printing effect. Therefore, in the choice of DTF film and ink, should be as far as possible to choose the same brand or the same series of products, Kenteer DTF film and DTF ink are to give full play to the advantages of the complementary effect between the printing effect is excellent. At the same time, attention should also be paid to the stability and shelf life of ink to avoid expired use or improper storage resulting in quality problems.

Kenteer DTF Ink quality standards include the following aspects:

1. Whiteness: DTF ink should have good whiteness. The higher the whiteness of high-quality white ink, the better the effect of printing.

2 uniformity: DTF ink should have good uniformity, that is, the pigment particles in the ink should be dispersed evenly, not large particles, uneven color.

3. Fluidity: the fluidity of DTF ink should be moderate, not too thick or too thin, affecting the printing effect.

4. Color saturation: the color of DTF ink should be high saturation, and the printing effect is natural and realistic.

5. Light resistance: printing ink should have a certain light resistance, to avoid the printed pattern because of long-term exposure to the sun or oxidation and loss of color.

6. Scratch and wear resistance: DTF ink should have a certain scratch and wear resistance, durable printing effect, not be easy to wear

7. Environmental protection: DTF ink should meet environmental protection standards, can not contain toxic and harmful substances, harmless to the human body and the environment.