DTF roll film manufacturers play a vital role in the printing industry, providing the necessary high quality roll film for the DTF printing process. Here are some key aspects of their roles:

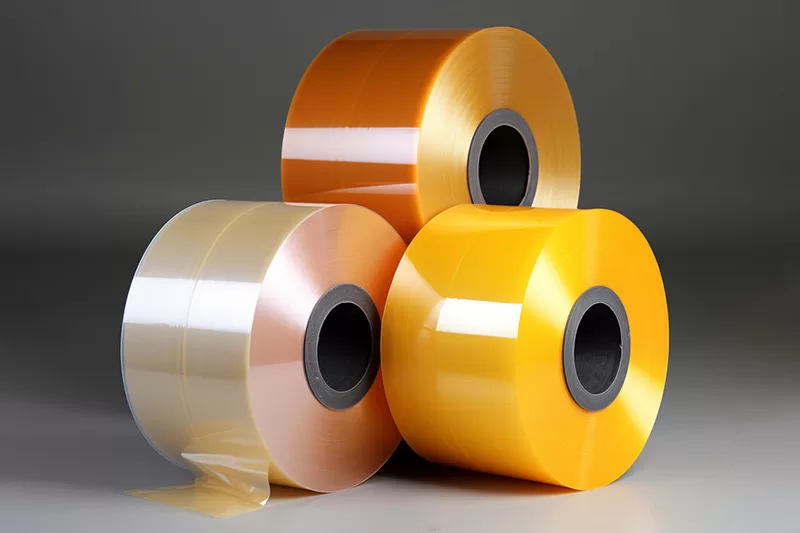

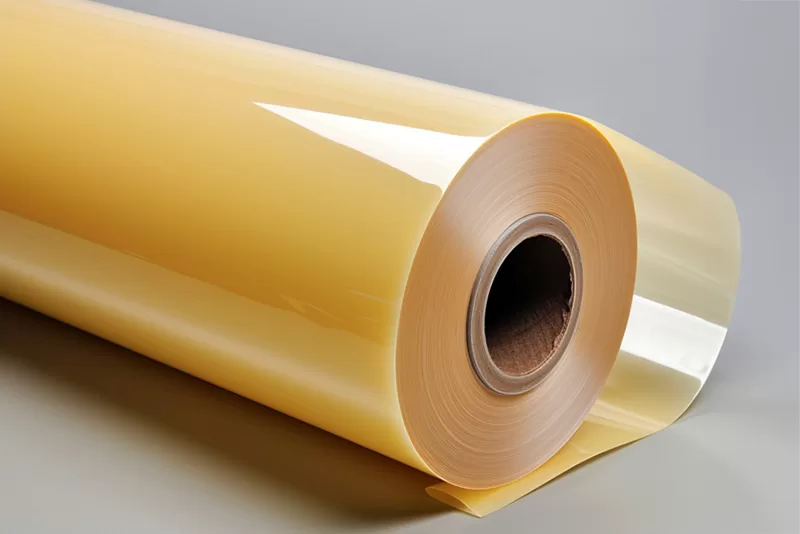

1. Production of DTF film rolls: DTF film roll manufacturers are responsible for the production of film rolls used in the DTF printing process. They use special equipment and processes to create the necessary PET (polyethylene terephthalate) film rolls such as printability, durability, and compatibility with DTF printing systems.

2. Quality Assurance: Manufacturers ensure that their DTF film rolls meet strict quality standards. Implement a comprehensive quality control process that monitors and tests films for ink adhesion, tensile strength, opacity and heat resistance. This ensures optimum performance of the film roll during printing and provides a high quality printed product.

3. Research and Development: Leading DTF roll film manufacturers invest in research and development efforts to improve the performance and capabilities of their roll films. They work to develop new formulations, coatings and techniques to improve print quality, durability and versatility. This continuous innovation has promoted the development of DTF printing industry.

4. Customization options: Manufacturers usually offer customization options for their DTF films to meet the specific requirements of different printing applications. This can include custom sizes, logo or design printing, special films and different finishes. Customization enables printers to achieve unique and personalized print products for customers.

5. Technical support and expertise: DTF roll film manufacturers provide technical support and expertise for printers using their roll film. They help eliminate glitches, provide guidance on optimal printing parameters, and offer advice on achieving the best possible print results. This support can help printers optimize the DTF printing process and overcome any possible challenges.

6. Industry partnerships and collaborations: Manufacturers often collaborate with other stakeholders in the printing industry, such as printer manufacturers, ink suppliers, and distributors. These partnerships foster innovation, knowledge exchange and the development of integrated solutions that enhance the overall printing experience at DTF.

7. Environmental considerations: Leading DTF film makers prioritize sustainability and environmental responsibility. They strive to reduce their environmental footprint by implementing environmentally friendly production practices, using recycled materials and complying with relevant environmental regulations. This ensures their films are environmentally conscious and in line with the industry's sustainability goals.

Generally speaking, DTF roll film manufacturers play a vital role in the printing industry, supplying high-quality roll film, promoting innovation, providing technical support, and contributing to the growth and success of DTF printing. Their expertise, product quality and commitment to customer satisfaction are critical to printers achieving great print results and meeting customer needs.