When choosing the right UV printer, it's essential to consider both price and features to ensure it meets your specific needs. Here's a guide to help you with price comparison and features analysis:

1. Determine Your Budget:

- Start by establishing a budget for your UV printer. This will help you narrow down your options and focus on models within your price range.

2. Compare Prices:

- Research different UV printer models from various manufacturers and compare their prices. Keep in mind that the price can vary depending on factors such as size, print quality, production speed, and additional features.

3. Consider Print Size and Resolution:

- Evaluate the maximum print size and resolution capabilities of the UV printers you are considering. Determine if they can accommodate the sizes and level of detail required for your specific printing applications.

4. Assess Production Speed:

- Review the production speed specifications of the UV printers. Consider the volume of printing you anticipate and choose a printer that can meet your production requirements without compromising print quality.

5. Examine Ink Options:

- Look into the types of ink supported by the UV printers. Consider factors such as ink cost, color gamut, and compatibility with different materials (e.g., rigid substrates, flexible media). Determine which ink option suits your printing needs and budget.

6. Evaluate Print Quality:

- Look for sample prints or demonstrations from the UV printer models you are considering. Assess the print quality, color accuracy, sharpness, and fine detail reproduction. Ensure that the printer can deliver the level of quality you require for your specific applications.

7. Additional Features:

- Consider any additional features or functionalities that may be important to you. This could include options like dual-layer printing, varnish or texture effects, automated calibration, or advanced color management. Evaluate if these features align with your printing requirements and if they justify any additional cost.

8. Warranty and Support:

- Check the warranty coverage and support options provided by the manufacturer. A reliable warranty and access to technical support can be crucial in case of any issues or maintenance needs.

9. Reviews and Reputation:

- Read customer reviews and seek feedback from other UV printer users. Consider the reputation of the manufacturer and their track record for product reliability, customer service, and ongoing software updates.

By comparing prices and analyzing the features of different UV printers, you can make an informed decision based on your budget and specific printing requirements. It's recommended to reach out to manufacturers or authorized resellers directly to get detailed quotes and specifications that align with your needs.

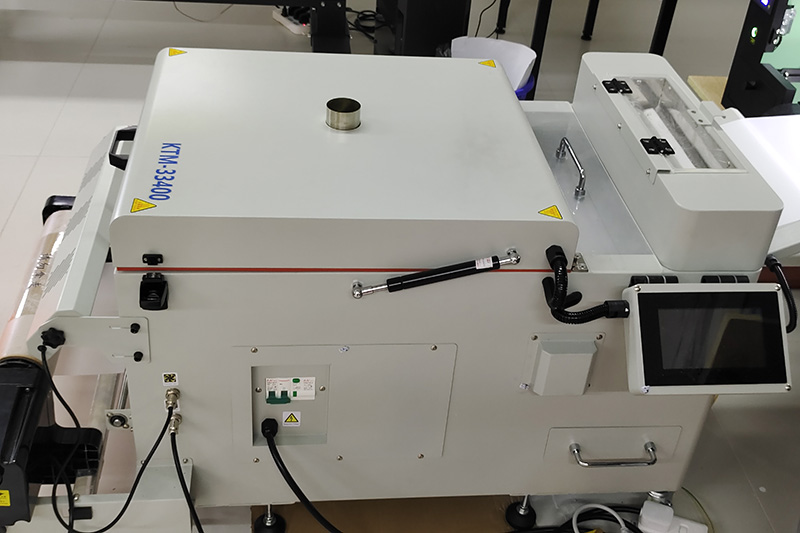

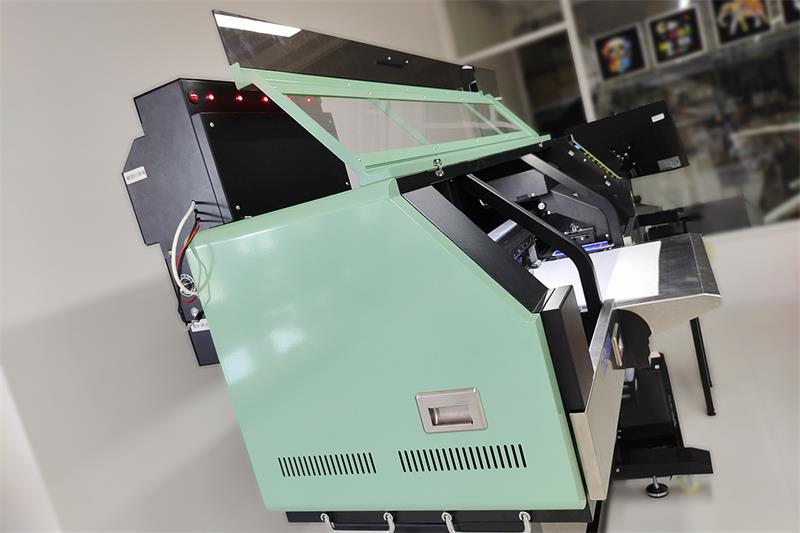

kenteer has launched DTF UV printers for customers . If you have any needs, you can contact us for a quote.