The A3 UV Flatbed Printer, a sophisticated printing solution designed for a wide range of industries, stands out with its remarkable technical features that deliver exceptional printing quality, versatility, and efficiency. This article delves into the intricacies of these features, exploring their significance and impact on the printing process.

1. Epson XP600 Print Heads: A Legacy of Precision and Reliability

At the heart of the A3 UV Flatbed Printer lies the renowned Epson XP600 print head technology, a testament to precision and reliability in the printing industry. Renowned for its ability to deliver sharp, vibrant prints with remarkable clarity, the XP600 print heads employ a droplet size of 3.5 picoliters, ensuring exceptional detail and color accuracy. This technology enables the printer to produce stunning prints with a resolution of up to 1440 x 1440 DPI, meeting the exacting demands of professional printing applications.

2. Blazing-Fast Printing Speeds: Efficiency at Your Fingertips

The A3 UV Flatbed Printer boasts impressive printing speeds, significantly enhancing productivity and streamlining workflow. In full-color mode, the printer can deliver an A3-sized print in just 10 minutes, making it an ideal choice for fast-paced environments that demand quick turnaround times. This remarkable speed is attributed to the printer's efficient design, which optimizes ink delivery and print head movement for maximum productivity.

3. Versatile Printing Capabilities: Embracing a World of Materials

The A3 UV Flatbed Printer shines in its versatility, effortlessly accommodating a wide variety of printing media. From phone cases and acrylic sheets to pens, helmets, and even ceramic, wood, metal, and glass, this printer effortlessly handles a diverse range of materials, opening up endless creative possibilities for designers, artists, and entrepreneurs alike. This versatility makes it a valuable asset in various industries, including promotional products, signage, and personalized gift creation.

4. UV Ink Technology: Unparalleled Durability and Vibrancy

The A3 UV Flatbed Printer utilizes cutting-edge UV ink technology, renowned for its exceptional durability and vibrant colors. UV inks are cured instantly upon contact with the print media, resulting in prints that are resistant to fading, scratching, and water damage. This remarkable durability makes UV-printed products ideal for outdoor applications, where they can withstand harsh weather conditions without compromising their visual integrity.

5. 6-Color Printing System: Expanding the Boundaries of Color Expression

The A3 UV Flatbed Printer features a 6-color printing system that incorporates CMYK, white, and varnish inks, unlocking a vast spectrum of color possibilities. The addition of white ink allows for vibrant prints on dark or transparent media, while the varnish ink adds a protective layer that enhances the print's resistance to wear and tear. This 6-color system empowers designers and artists to explore creative new frontiers, producing stunning prints with exceptional color depth and dimensionality.

The A3 UV Flatbed Printer emerges as a technological marvel in the world of printing, seamlessly blending precision, versatility, and efficiency. Its Epson XP600 print heads, lightning-fast printing speeds, wide media compatibility, UV ink technology, and 6-color printing system collectively elevate the printing experience to new heights. This printer is undoubtedly a game-changer for industries seeking exceptional print quality, unrivaled durability, and boundless creative possibilities.

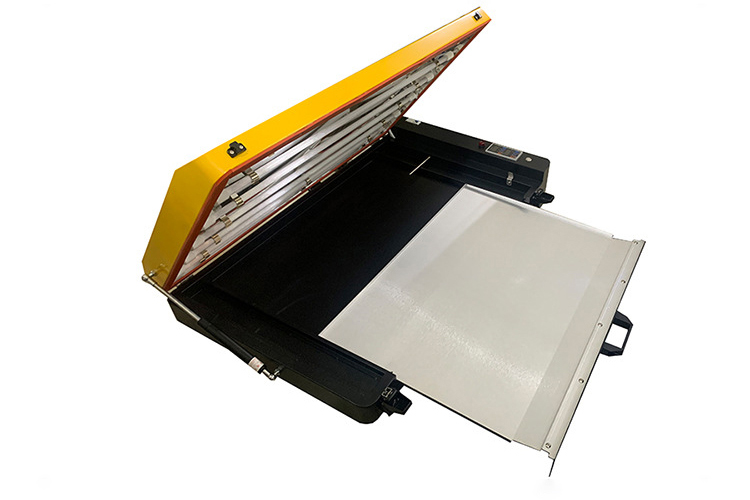

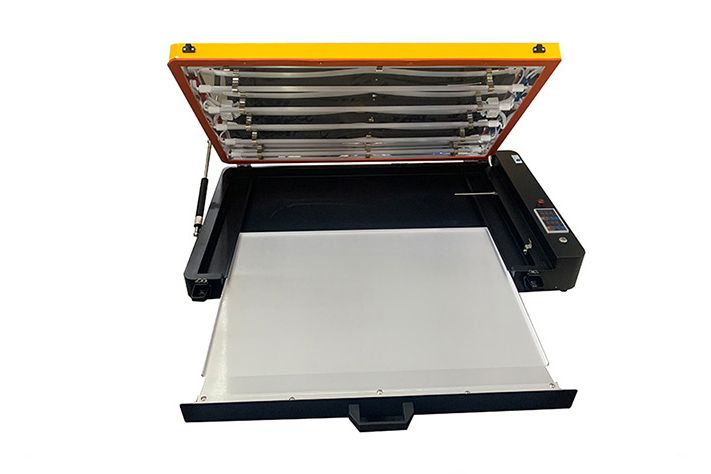

Kenteer A3 UV Flatbed Printer parameters are as follows:

Print Head:2 Pcs Epson XP600 Heads

Printing Speed:12-Pass Full-Color Printing, 10 Mins/A3 Size

Printing Height:Max 12cm

Ink Type:UVInk

Ink Channel:CMYK WW +6 Varnish

Print Media:Phone Case,Acrylic,Pen,Helmet,Ceramic,Wood,Metal,Glass...

Working Environment:Temperature 0°C ~30°C Humidity 40%-70%

Printing Resolution:1440*1440DPI

Photo Format Type:TIF,JPG,PDF,EPS,PS,PNG..

Voltage:110-220V 50-60HZ 300W

Machine Size:80*75*50cm

Packing Size:100*80*70cm,0.56cbm

Net/Gross Weight:65Kg/105Kg

If you have product purchasing needs, you can contact us.