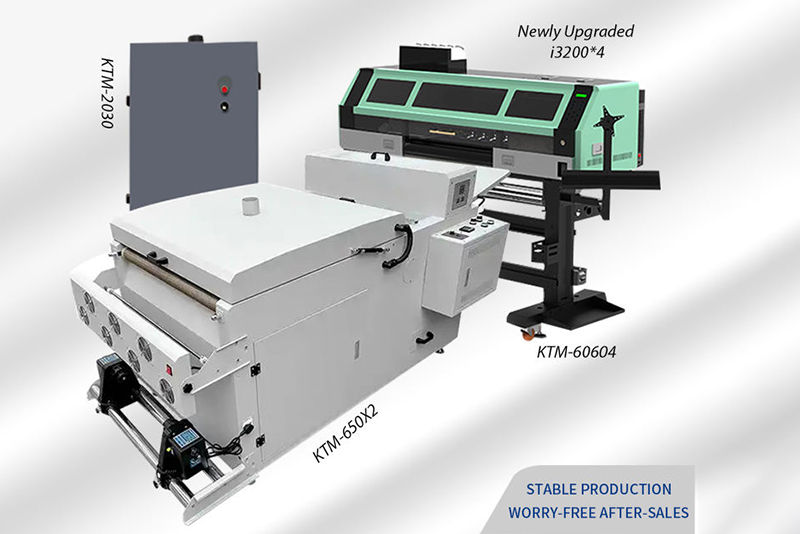

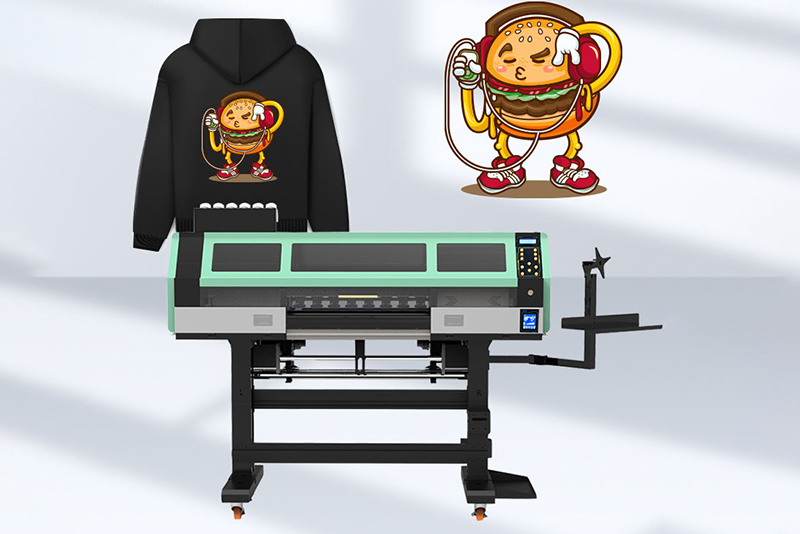

In the realm of digital printing, speed and efficiency are paramount. For wide format printing machines, the KTM-606501A emerges as a game-changer, offering unparalleled capabilities for high-speed quad head printing.

Exceptional Versatility: A Wide Range of Compatible Materials

The KTM-606501A is engineered to handle a diverse array of materials, including nylon, chemical fiber, cotton, leather, swimwear, wetsuit, PVC, and EAC. This versatility allows businesses to expand their printing horizons and cater to a wider customer base.

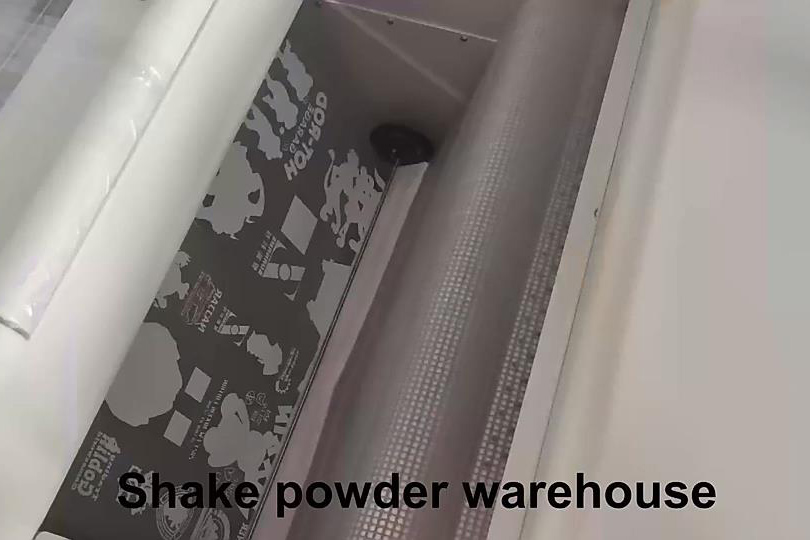

Precision Powder Control: Ensuring Optimal Results

At the heart of the KTM-606501A lies its advanced powder control system. With shaking powder control and powder spreading control, users can meticulously adjust the direction and amount of powder applied, ensuring consistent and high-quality prints even at high speeds.

Enhanced Efficiency: Automatic Powder Return and Reel Function

To maximize productivity, the KTM-606501A features an automatic powder return gear with multiple speed settings. This feature automates the powder recycling process, reducing downtime and increasing print efficiency. The integrated reel function further enhances speed by automatically winding the finished material for seamless transitions.

Optimal Temperature Management: Front Guide Heating to Cold Air Cooling

For optimal drying and curing of prints, the KTM-606501A employs a multi-zone temperature control system. Front guide heating ensures prints dry quickly, while the upper drying curing process further enhances their durability. A single row of cold air cooling effectively dissipates heat, preventing damage to delicate materials.

User-Friendly Interface: Intuitive Operation and Real-Time Monitoring

The KTM-606501A boasts an intuitive user interface that simplifies operation and maintenance. Real-time monitoring features provide valuable information on the machine's status, allowing operators to make informed adjustments for optimal performance.

Compact Design and Energy Efficiency: Maximizing Space and Minimizing Costs

Despite its impressive capabilities, the KTM-606501A maintains a compact size, allowing for easy integration into existing workflows. Its energy-efficient design further reduces operating costs, making it an economical choice for businesses seeking high-speed printing solutions.

The KTM-606501A represents a breakthrough in digital printing technology. Its exceptional versatility, precision powder control, enhanced efficiency, optimal temperature management, user-friendly interface, and compact design make it the ideal solution for high-speed quad head printing. By investing in the KTM-606501A, businesses can unlock new possibilities for productivity, expand their printing capabilities, and deliver unparalleled results.

If you have product purchasing needs, you can contact us