The apparel industry thrives on customization, efficiency, and high-quality output. Traditional methods like screen printing, while effective, often come with limitations in terms of design complexity, turnaround times, and cost-effectiveness, especially for smaller runs. This is where Direct-to-Film (DTF) printing technology emerges as a revolutionary solution, and the KTM-1802 DTF printer stands at the forefront of this innovation.

Understanding DTF Printing

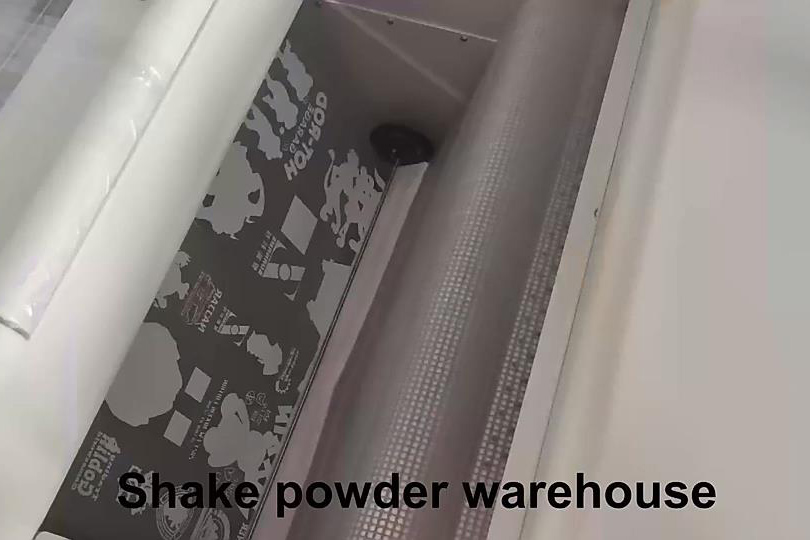

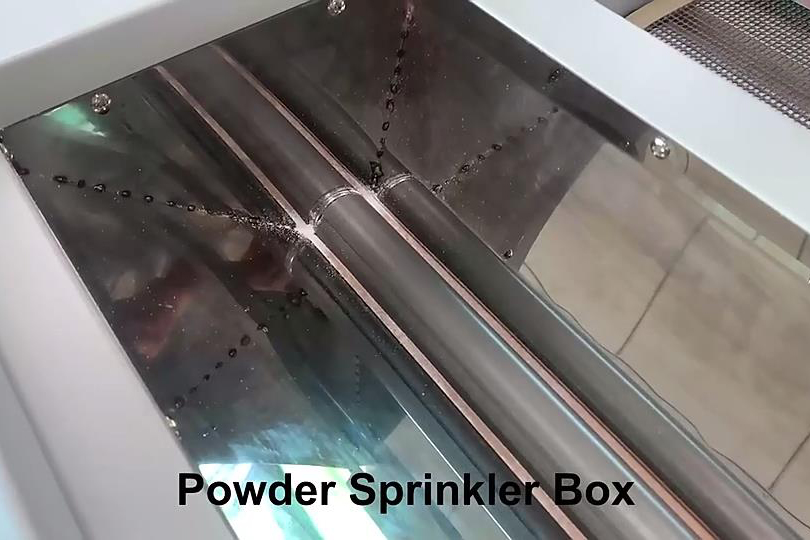

DTF printing is a heat transfer process that involves printing designs onto a special film, which is then coated with a powdered adhesive. The design is then transferred onto the fabric using a heat press, resulting in vibrant, full-color prints with excellent durability and washability.

The KTM-1802: A Powerhouse of DTF Printing

The KTM-1802 is a 2-head high-speed digital printing machine specifically designed for DTF applications. Its features cater directly to the needs of the apparel industry, offering a range of benefits:

High-Quality Output Equipped with two high-resolution 13200-A1 printheads, the KTM-1802 delivers exceptional print quality with sharp details and vibrant colors. This ensures that intricate designs and photographic images are reproduced flawlessly on garments.

Versatility and Customization DTF printing allows for printing on a wide variety of fabrics, including cotton, polyester, blends, and even dark-colored materials. This opens up a world of possibilities for apparel decoration, from t-shirts and hoodies to sportswear, bags, and accessories.

Efficiency and Speed The KTM-1802 boasts a printing width of 1.8 meters and a high-speed printing capability, significantly reducing production time compared to traditional methods. This is particularly beneficial for businesses dealing with large orders or tight deadlines.

Cost-Effectiveness DTF printing eliminates the need for expensive screens and setup costs associated with screen printing. This makes it a cost-effective solution for both small and large production runs, allowing businesses to offer competitive pricing while maintaining high-profit margins.

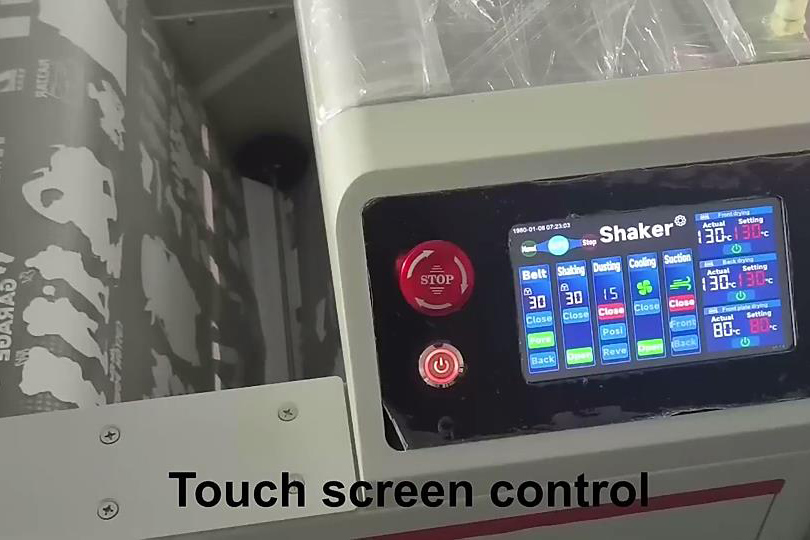

User-Friendly Operation The KTM-1802 is designed for ease of use, featuring an intuitive interface and automated functions such as ink level monitoring and paper feed systems. This minimizes the learning curve and ensures smooth operation even for those new to DTF printing.

Durability and Reliability The printer's robust construction and high-quality components ensure long-lasting performance and minimal maintenance requirements. This translates to increased uptime and reduced operational costs for businesses.

Applications in the Apparel Industry

The KTM-1802 DTF printer unlocks a multitude of applications within the apparel industry:

Personalized Apparel DTF printing allows for on-demand printing of custom designs, names, and logos, catering to the growing demand for personalized clothing and accessories.

Fashion and Apparel Brands Fashion designers and clothing brands can leverage DTF printing to create unique collections with intricate designs and vibrant colors, setting themselves apart in a competitive market.

Promotional Products Businesses can utilize DTF printing to create branded merchandise such as t-shirts, caps, and bags for promotional events, corporate gifting, and employee uniforms.

Sportswear and Athleisure The durability and washability of DTF prints make it ideal for sportswear and athleisure wear, allowing for vibrant designs and logos that withstand rigorous activity.

Home Decor and Textiles DTF printing extends beyond apparel, enabling customization of home decor items like cushion covers, curtains, and tablecloths.

The Future of Apparel Decoration

The KTM-1802 DTF printer represents a significant advancement in apparel decoration technology. Its combination of high-quality output, versatility, efficiency, and cost-effectiveness makes it an invaluable tool for businesses of all sizes. As the demand for customization and on-demand production continues to grow, DTF printing is poised to become the preferred method for apparel decoration, and the KTM-1802 is leading the way in this exciting evolution.

If you have product purchasing needs, you can contact us.