The KTM-1904 DTF printer has emerged as a game-changer in the apparel industry, offering a versatile and efficient solution for garment decoration. This advanced technology utilizes thermal transfer to apply vibrant, full-color designs onto various fabrics, unlocking a new realm of possibilities for fashion brands, designers, and custom apparel businesses.

Versatility and Fabric Compatibility

One of the key advantages of the KTM-1904 DTF printer is its remarkable versatility. Unlike traditional printing methods that often have limitations regarding fabric type and color, DTF printing works seamlessly on a wide range of materials, including cotton, polyester, blends, nylon, leather, and more. This opens doors for creating unique designs on t-shirts, hoodies, sportswear, jackets, bags, and other apparel items, regardless of their composition or color.

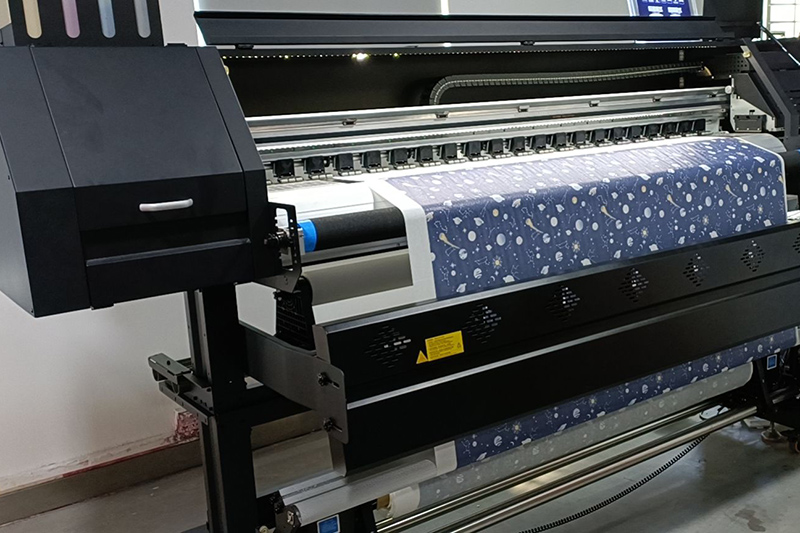

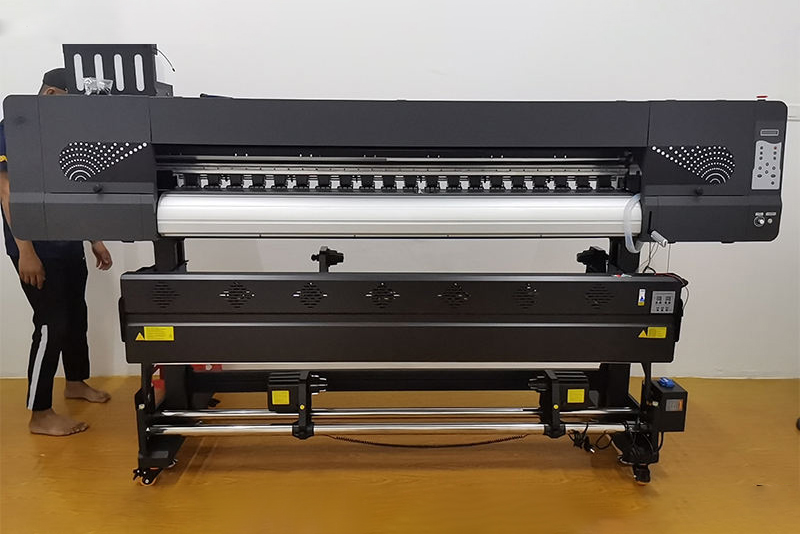

High-Quality Prints and Durability

The KTM-1904 boasts a 1.9-meter printing width and utilizes four high-resolution 13200-A1 printheads, ensuring exceptional print quality with sharp details and vibrant colors. The printer's auto constant temperature drying system guarantees uniform heat distribution, allowing for optimal ink absorption and producing prints that are not only visually appealing but also highly durable and resistant to fading, cracking, and peeling, even after multiple washes.

Efficiency and Productivity

Equipped with an exclusive all-aluminum ink stack, the KTM-1904 ensures reliable and consistent ink flow, minimizing downtime and maximizing productivity. The large-capacity ink tanks with intelligent low-ink alarm systems further enhance efficiency by enabling continuous printing without interruptions. Additionally, the printer features a lack-of-paper alarm system, promoting safe and convenient operation.

Customization and Personalization

The KTM-1904 empowers businesses to cater to the growing demand for personalized apparel. Whether it's individual names, unique graphics, or small-batch custom designs, this DTF printer allows for on-demand printing, eliminating the need for minimum order quantities and offering cost-effective solutions for both large and small businesses. This capability is particularly beneficial for fashion brands looking to offer limited-edition collections, personalized merchandise, or cater to niche markets.

Integration with Design Software

The KTM-1904 seamlessly integrates with popular RIP software such as Maintop and PhotoPrint, providing users with a comprehensive design and printing workflow. This allows for easy manipulation of images, creation of intricate designs, and precise color management, ensuring that the final printed output matches the intended vision.

Sustainability Considerations

Compared to traditional screen printing or dye-sublimation methods, DTF printing generally uses less water and energy, contributing to a more sustainable production process. Additionally, the ability to print on demand reduces waste associated with overproduction and unsold inventory.

Applications in the Apparel Industry

The KTM-1904 DTF printer finds applications in various segments of the apparel industry:

Fashion Brands Creating unique collections, limited-edition pieces, and personalized garments.

Sportswear Manufacturers Printing team logos, names, and numbers on jerseys, athletic wear, and accessories.

Promotional Apparel Companies Producing custom t-shirts, hoodies, and other items for events, businesses, and organizations.

E-commerce Businesses Offering on-demand printing services for personalized apparel and accessories.

Small Businesses and Designers Expanding product offerings and providing customization options without significant investment.

The KTM-1904 DTF printer has revolutionized apparel decoration, offering a powerful combination of versatility, efficiency, and high-quality output. Its ability to print on various fabrics, coupled with its customization capabilities, makes it an invaluable tool for businesses of all sizes within the fashion industry. As the demand for personalized and unique apparel continues to grow, the KTM-1904 is poised to play a pivotal role in shaping the future of garment decoration.

If you have product purchasing needs, you can contact us.