The Kenteer KTM-A15 UV Printer represents a significant advancement in digital printing technology, offering a versatile and efficient solution for a wide range of applications. With its impressive specifications and innovative features, the KTM-A15 is poised to disrupt traditional printing methods and unlock new creative possibilities for businesses across various sectors. This article will delve into the market applications of the KTM-A15 UV Printer, explore the current technology trends driving the UV printer market, and analyze how this particular model contributes to the evolving landscape of digital printing.

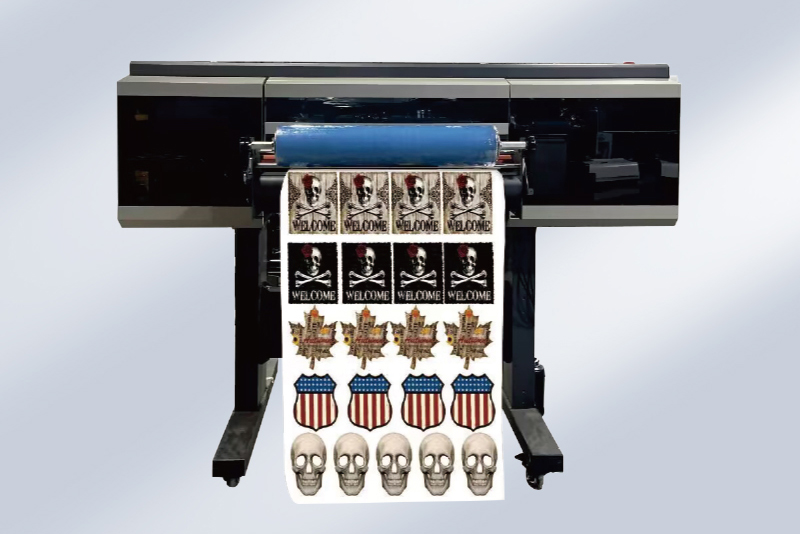

The KTM-A15 UV Printer caters to a diverse market, including signage and graphics, personalized gifts, promotional items, packaging, and industrial printing. Its ability to print directly onto a vast array of substrates, including wood, metal, glass, acrylic, ceramics, and textiles, opens doors for customized production and on-demand printing. Businesses can leverage the KTM-A15 to create vibrant and durable signage, eye-catching promotional materials, personalized phone cases, bespoke packaging, and even custom-designed furniture. The versatility of this UV printer allows for rapid prototyping and small-batch production, making it an ideal solution for entrepreneurs, small businesses, and large-scale operations alike.

One of the key drivers behind the growing popularity of UV printers is their ability to produce high-quality prints with exceptional durability. The KTM-A15 utilizes UV-curable inks, which instantly dry upon exposure to UV light. This process eliminates the need for drying time and prevents smudging or bleeding, resulting in sharp, vibrant images with excellent color reproduction. The UV-cured ink is also highly resistant to scratches, fading, and environmental factors, ensuring long-lasting prints for both indoor and outdoor applications. This durability is a significant advantage for businesses looking to create products that withstand wear and tear, especially in demanding environments.

The KTM-A15 UV Printer incorporates advanced features that contribute to its efficiency and performance. The dual XP600 printheads deliver high-resolution printing at impressive speeds, allowing for faster turnaround times and increased productivity. The Maitop 6.1 printing software offers a user-friendly interface and precise control over print parameters, enabling users to optimize print quality and efficiency. The inclusion of white and varnish inks expands creative possibilities, enabling users to print on dark substrates and achieve unique textured effects. Furthermore, the KTM-A15's compact design and relatively small footprint make it a practical choice for businesses with limited space.

The UV printer market is witnessing several key technology trends that are shaping the future of digital printing. One notable trend is the development of eco-friendly UV inks with lower VOC emissions, addressing environmental concerns associated with traditional printing methods. Another trend is the increasing adoption of automation and robotics in UV printing workflows, further enhancing productivity and reducing labor costs. The development of specialized UV inks for specific applications, such as textiles and flexible packaging, is also expanding the reach of UV printing technology. The KTM-A15, with its versatile ink configuration and advanced features, positions itself well within these evolving trends.

Furthermore, the demand for personalized and customized products is driving innovation in the UV printer market. The KTM-A15 UV printer caters to this demand by offering a platform for creating unique, on-demand products that cater to individual customer preferences. This capability is particularly valuable in the e-commerce and personalized gifting sectors, where consumers are increasingly seeking bespoke items.

The KTM-A15 UV Printer represents a significant step forward in the evolution of digital printing technology. Its versatility, speed, and ability to produce high-quality, durable prints make it an attractive solution for businesses across a wide range of industries. As the UV Printer market continues to evolve, driven by technological advancements and changing consumer demands, the KTM-A15 is well-positioned to meet the growing need for efficient, on-demand, and customized printing solutions. Its ability to print on diverse substrates, combined with its advanced features and user-friendly software, makes it a valuable asset for businesses looking to embrace the future of digital printing. The KTM-A15 UV printer is not just a printing device; it is a tool for innovation and creativity, empowering businesses to explore new possibilities and expand their horizons