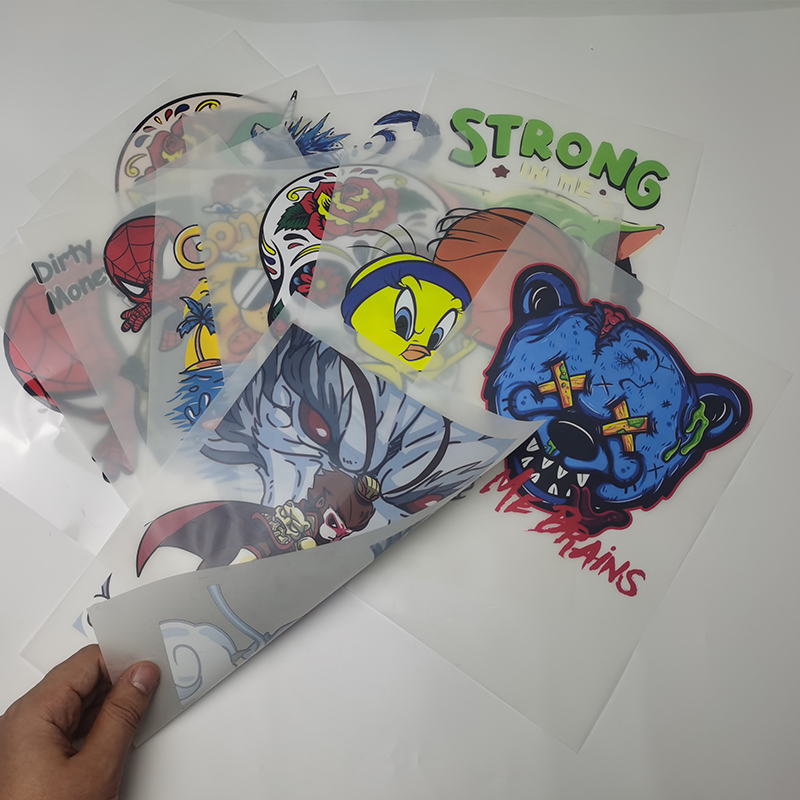

DTF (direct to film) PET film printing is popular for its versatility and high quality results. However, a common problem faced by DTF PET film printer owners is the lack of color vibrancy and intensity of printed images. This lack of color can be frustrating and affect the overall visual appeal of a printed product. Together today we will explore some of the key factors that lead to a lack of color in DTF PET film prints and examine solutions.

Insufficient ink density

One of the main reasons for the lack of color in DTF PET film printing patterns is insufficient ink density. Colors may fade or fade if ink is applied too thinly or insufficiently layered. Make sure your printer settings and ink density are adjusted correctly to achieve the desired color intensity. Experiment with different ink density settings and test prints to find the best balance between ink consumption and vivid color reproduction.

Incorrect color profile

Color profiles play a vital role in ensuring accurate color reproduction in DTF PET film printing. If the color profile is not set correctly or does not match the combination of printer, ink and PET film, it may cause the color to lack vibrancy. Check that the correct color profile is selected and calibrated correctly for your particular printer and ink system. Consider consulting a color expert or utilizing color management tools to ensure accurate color profiles for vibrant print results.

Incompatible inks and PET films

Using incompatible inks or PET films can also cause DTF prints to lack color vibrancy. Make sure the ink and PET film are specially formulated to be compatible with each other. Certain ink and PET film combinations may not interact optimally, resulting in inconsistent or reduced color intensity. Choose ink and PET film products from reputable manufacturers and ensure compatibility with product specifications or compatibility testing.

Ink curing or drying is insufficient

Improper curing or drying of the ink can affect the color vibrancy of images printed on DTF PET film. Incomplete curing or insufficient drying time of the ink may result in color casts or muted colors. Make sure the printer settings and curing or drying process are properly calibrated according to the ink and PET film manufacturer's recommendations. Consider using specialized curing equipment or following specific drying guidelines for optimal color vibrancy.

Poor image quality or resolution

The quality and resolution of the printed image can affect color vividness. Low-resolution images or images with insufficiently saturated colors may result in dull prints. Take advantage of high-quality, high-resolution images with vibrant color representation for optimal print results. Color correction and image enhancement techniques are performed, if necessary, to ensure final prints are vibrant in color.

Printer Maintenance and Performance

Regular printer maintenance is essential for optimum performance and color reproduction. Clogged printheads or ink lines can affect ink flow and cause inconsistency or lack of color vibrancy. Follow the manufacturer's recommended maintenance procedures, including cleaning and printhead maintenance, to ensure smooth ink flow and vibrant color output.

So, lack of color vibrancy in DTF PET film printed graphics can be attributed to a number of factors including insufficient ink density, incorrect color profile, incompatibility of ink and PET film, insufficient ink curing or drying, poor image quality or resolution, and printer maintenance problem. By addressing these factors and implementing appropriate solutions such as adjusting ink density settings, using correct color profiles, ensuring compatibility between inks and PET films, optimizing curing or drying processes, using high quality images, and maintaining printers, DTF PET film printer owners can achieve vibrant and visually appealing color results. Remember to experiment, consult an expert, and follow manufacturer guidelines to achieve the best color reproduction in DTF PET film printing.