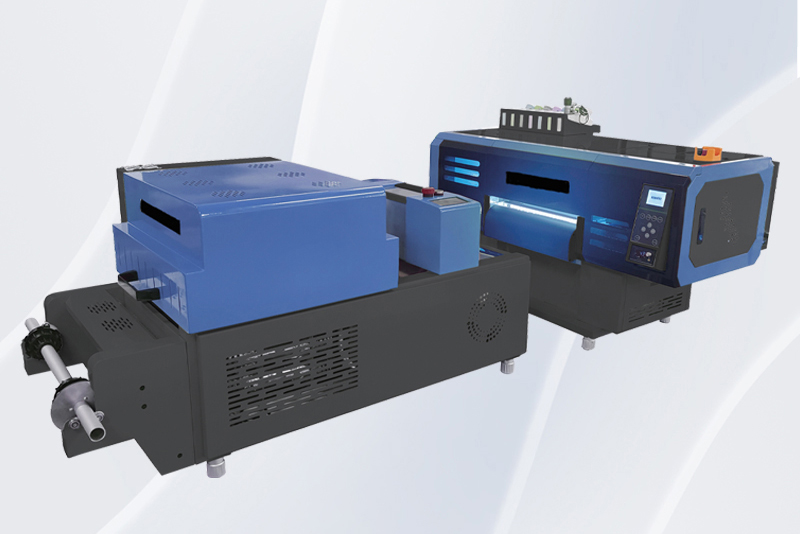

In the realm of garment printing, the DTF (Direct to Film) technique has emerged as a frontrunner, captivating the industry with its versatility and exceptional results. At the forefront of this innovation stands the KTM-A45 DTF Printer, a masterpiece of engineering from Kenteer. This article delves into the intricate workings of this remarkable device, unraveling the magic behind its ability to transform designs into vibrant, long-lasting imprints on a diverse range of fabrics.

Unveiling the DTF Printing Process: A Step-by-Step Journey

The KTM-A45 DTF Printer employs a meticulous multi-stage process to achieve its stunning outcomes. Let's embark on a journey to uncover the intricacies of each step:

1. Design Creation and Preparation

The creative spark ignites with the conception of the design, whether it's a captivating logo, an eye-catching graphic, or a personalized message. This digital artwork is then meticulously prepared for the printing process, ensuring optimal quality and compatibility with the DTF technique.

2. Printing onto PET Film

The KTM-A45 DTF Printer, takes center stage as it receives the prepared design. With its Epson F1080/I1600 dual print heads, the printer meticulously deposits pigmented inks onto a specialized PET film. These inks, carefully formulated for DTF printing, boast exceptional adhesion and vibrancy, promising exceptional transfer onto the target material.

3. Powdering and Drying

Once the design has been flawlessly imprinted onto the PET film, it undergoes a crucial step: powdering. A fine layer of powder is meticulously applied to the wet ink, ensuring flawless transfer during the subsequent heat press stage. This delicate process is followed by drying, which gently cures the ink, preparing it for the next phase.

4. Heat Press Transfer: Bonding Design and Fabric

The heart of the DTF process lies in the heat press transfer. The powdered and dried PET film, bearing the design, is carefully placed onto the target fabric. Under the precise control of the heat press, intense heat and pressure are applied, causing the powder to melt and the ink to transfer onto the fabric. This intimate fusion creates a durable and vibrant bond between the design and the garment.

5. Tearing and Finishing Touches

The final act of the DTF printing drama involves the removal of the PET film, revealing the transferred design in all its splendor. With a gentle tear, the film separates from the fabric, leaving behind the pristine design. Any remaining powder is then brushed away, and the garment is ready to showcase its newfound adornment.

If you have product purchasing needs, you can contact us.