In the world of printing, achieving vibrant and durable designs is essential. One popular ink choice that has revolutionized the industry is plastisol ink. From screen printing to heat transfers, plastisol ink offers unique advantages that set it apart from other types of ink. In this article, we will delve into the world of plastisol ink, exploring its composition, applications, and how it differs from other ink options. By the end, you will have a comprehensive understanding of plastisol ink and its potential to enhance your printing projects and promote your brand, such as Kenteer.

What is Plastisol Ink?

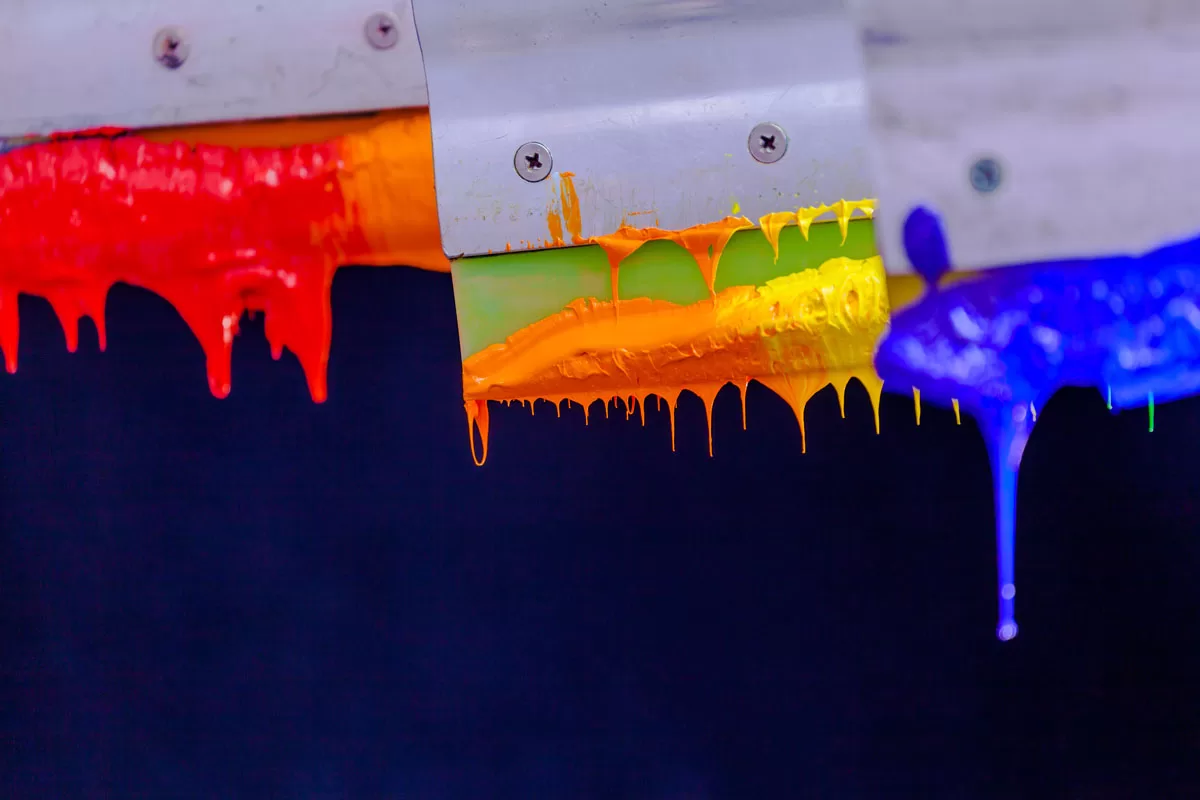

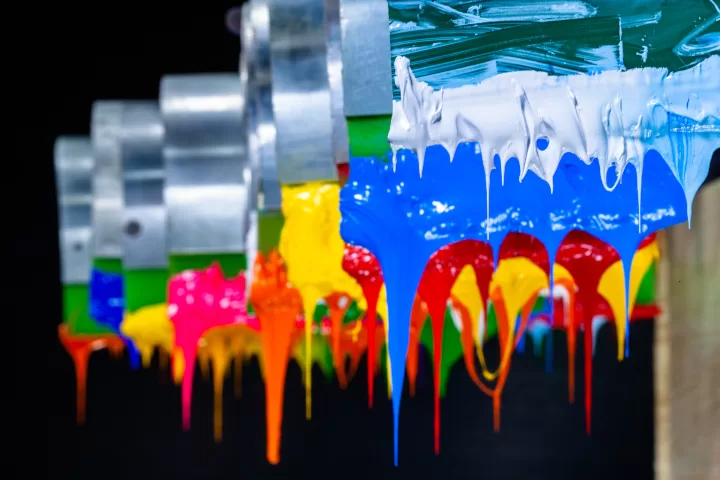

Plastisol ink is a type of screen printing ink that consists of a PVC (polyvinyl chloride) resin suspended in a plasticizer.

Unlike other inks that dry through evaporation, plastisol ink requires heat to cure and form a solid bond with the fabric or substrate.

Composition

Plastisol ink is typically composed of the following components:

PVC resin: Provides the ink's color and acts as the main binder.

Plasticizer: Enhances the ink's flow and flexibility.

Pigments: Add color to the ink and determine its opacity and vibrancy.

Additives: Improve ink performance, such as adhesion, opacity, or special effects.

Key Characteristics and Advantages of Plastisol Ink

Opacity and Vibrancy

Plastisol ink offers exceptional opacity, making it suitable for printing on both light and dark-colored fabrics. It provides vibrant, solid colors that pop, even on challenging substrates.

Durability and Washability

Once cured, plastisol ink forms a permanent bond with the fabric or substrate, resulting in long-lasting and highly durable prints. Plastisol prints can withstand numerous wash cycles without fading or cracking.

Versatility in Printing Applications

Plastisol ink is widely used in screen printing, heat transfers, and specialty applications. It can be applied to various fabrics, including cotton, polyester, blends, and even non-textile materials.

Excellent Shelf Life

Unlike water-based or solvent-based inks that can dry out quickly, plastisol ink has an extended shelf life. It remains in a usable state for a longer period, allowing for easier storage and reduced ink waste.

How Does Plastisol Ink Differ from Other Ink Types?

Water-Based Ink: Water-based ink is another popular choice for screen printing, especially for eco-conscious printers. Plastisol ink differs from water-based ink in terms of composition, curing method, and characteristics. Plastisol ink offers superior opacity, vibrant colors, and durability compared to water-based ink. Water-based ink, on the other hand, provides a softer hand feel and is more environmentally friendly.

Discharge Ink: Discharge ink is a water-based ink that contains discharge agents capable of removing the dye from the fabric. Plastisol ink is different from discharge ink as it covers the fabric with a layer of color instead of removing the existing color. Plastisol ink offers more consistent and vibrant results, especially on dark-colored fabrics.

Solvent-Based Ink: Solvent-based ink, often used in industrial printing applications, relies on solvents to keep the pigments in suspension.Plastisol ink does not contain solvents, making it easier to work with and less harmful to the environment. Solvent-based inks may have faster drying times, but they can pose health and safety risks due to the volatile organic compounds (VOCs) present in the solvents.

UV-Curable Ink: UV-curable ink is a type of ink that cures instantly when exposed to ultraviolet (UV) light. Plastisol ink, in contrast, requires heat to cure and achieve optimal adhesion and durability. UV-curable ink offers high printing speeds and can be used on a wide range of substrates, but it may not provide the same level of flexibility and durability as plastisol ink.

Applications of Plastisol Ink:

Screen Printing: Plastisol ink is widely used in screen printing due to its vibrant colors, opacity, and excellent adhesion to various fabrics. It is ideal for printing on garments, textiles, promotional items, and other fabric-based materials.

Heat Transfers: Plastisol ink is used in heat transfer applications, where the ink is first screen printed onto a release paper or PET film, and then heat transferred onto the fabric.

This method allows for detailed and full-color designs on a wide range of fabrics, including cotton, polyester, and blends.

Specialty Applications: Plastisol ink is also utilized in specialty applications, such as printing on non-textile materials like plastics, metals, or ceramics.

It offers excellent adhesion and durability on these substrates, making it suitable for promotional products, signage, and industrial applications.

Promoting Your Brand with Plastisol Ink

Quality and Consistency: To promote your brand effectively, it's crucial to ensure that the plastisol ink you use is of high quality. Choose reputable suppliers, like Kenteer, that provide consistent and reliable plastisol ink formulations.

Customization and Color Matching: Plastisol ink allows for customization and color matching to maintain brand consistency. Work with suppliers who offer a wide range of colors and the ability to create custom shades to accurately represent your brand identity.

Collaboration with Printing Professionals: Collaborate with experienced printing professionals who are knowledgeable in working with plastisol ink. They can provide valuable insights, guidance, and assistance in achieving the desired print quality and durability for your brand.

Showcasing Durability and Vibrancy: Highlight the durability and vibrancy of plastisol ink in your marketing materials. Emphasize its ability to withstand multiple wash cycles, retain color vibrancy, and maintain the integrity of your brand's designs over time.

Plastisol ink stands out as a versatile and durable printing solution, offering vibrant colors, excellent opacity, and long-lasting prints. Its unique composition and curing process differentiates it from other ink types, providing advantages in terms of durability, versatility, and ease of use. By understanding the characteristics and applications of plastisol ink, brands like Kenteer can leverage its benefits to enhance their promotional efforts and create visually stunning designs. Whether you're screen printing, utilizing heat transfers, or exploring specialty applications, plastisol ink is an excellent choice to showcase your brand's creativity and leave a lasting impression.