When using a DTF printer, it's essential to troubleshoot ink issues such as clogging and color mixing to ensure optimal print quality. Here are some preventive measures and troubleshooting steps:

Preventing Clogging and Color Mixing:

1. Quality Ink: Use high-quality, manufacturer-approved DTF ink that is specifically formulated for the printer. Inferior or incompatible inks can lead to clogging and color mixing issues.

2. Proper Storage: Store the ink in a cool and dry environment, away from direct sunlight, extreme temperatures, and humidity. Follow the manufacturer's recommendations for ink storage conditions.

3. Shake Ink Cartridges: Before installing ink cartridges, gently shake them to ensure proper mixing of the ink. This helps prevent settling or separation of pigments.

4. Regular Maintenance: Perform regular maintenance routines recommended by the printer manufacturer, such as automated cleaning cycles or manual cleaning procedures. This helps prevent ink buildup and clogging in the print heads.

Troubleshooting Clogging Issues:

1. Nozzle Check: Perform a nozzle check to identify any clogged nozzles. This test pattern shows if any ink channels are blocked or not firing properly.

2. Cleaning Cycle: Run the printer's automated cleaning cycle to clear clogged nozzles. This process usually involves flushing ink through the print heads to remove dried or stuck ink.

3. Manual Cleaning: If automated cleaning fails to resolve the clogging issue, consult the printer's user manual or contact the manufacturer for guidance on manual cleaning procedures. This may involve using specialized cleaning solutions, swabs, or other recommended tools.

Troubleshooting Color Mixing Issues:

1. Proper Ink Loading: Ensure that each ink color is correctly loaded into its designated cartridge. Incorrect placement can lead to color mixing during printing.

2. Purge and Test Prints: Before starting a new print job, purge the printer by printing a few test prints on scrap material. This helps clear any residual ink and ensures accurate color reproduction.

3. Color Calibration: Perform color calibration procedures as recommended by the printer manufacturer or software. This helps fine-tune color profiles and ensures accurate color output.

4. Ink Density and Saturation Settings: Adjust the ink density and saturation settings in the printer software or RIP (Raster Image Processor) to achieve the desired color intensity without causing color bleeding or mixing.

If troubleshooting steps do not resolve the ink issues, it is advisable to contact the printer manufacturer's technical support or consult a professional technician who specializes in DTF printers. They can provide further guidance or perform diagnostics to identify and resolve more complex ink-related problems.

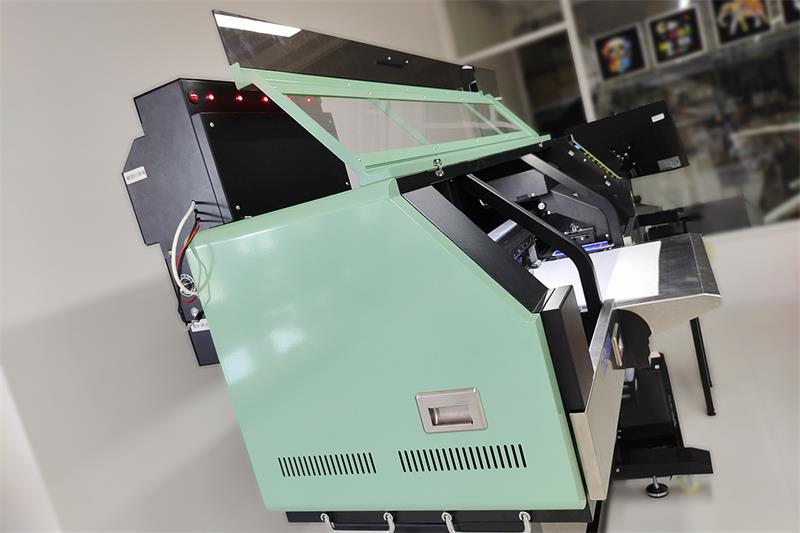

kenteer has launched DTF Printer for customers . If you have any needs, you can contact us for a quote.