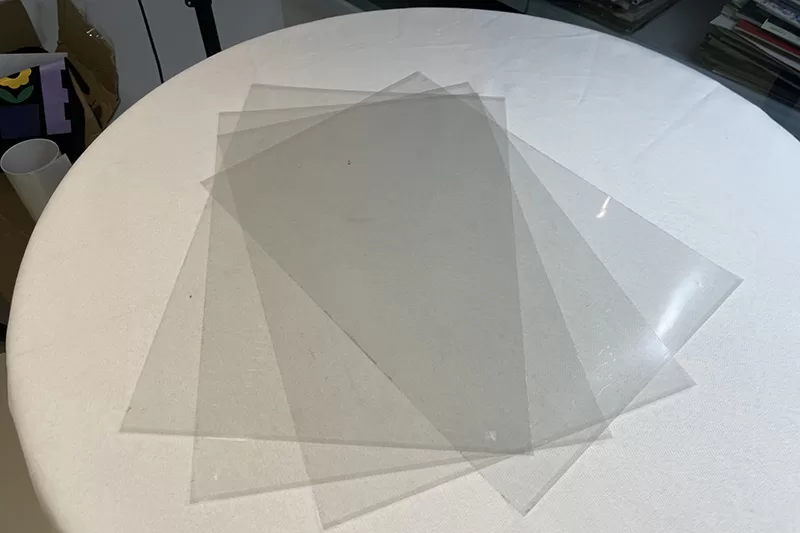

Proper handling and storage of UV DTF film is critical to maintaining its quality and performance. Here are some tips to ensure proper handling and storage of UV DTF films:

1. Avoid touching the printing surface: When handling UV DTF film, it is important to avoid touching the printing surface with bare hands or dirty gloves. Oil, dirt or fingerprints can affect the adhesion and print quality of UV inks. Wear clean gloves or use handling tools to minimize contact with the printed surface.

2. Store in a controlled environment: UV DTF films should be stored in a controlled environment to protect them from adverse conditions. Ideally, store films in a cool, dry and clean area with temperature and humidity control. Extreme temperatures, high humidity, and exposure to direct sunlight can negatively affect the quality of your film.

3. Use protective packaging: UV DTF film should be packed and stored in protective packaging to prevent dust, humidity and physical damage. Store film in its original packaging, or use a storage sleeve or bag specifically designed to protect film. Make sure the package is airtight to maintain a clean and moisture-free environment.

4. Handle carefully during the printing process: put the UV DTF film into the printer or during the printing process, please handle it carefully to avoid creases, bends or scratches on the film. Follow the printer manufacturer's instructions for proper loading and handling techniques. Avoid excessive pulling or force as this can damage the film.

5. Avoid excessive exposure to light: UV DTF film is sensitive to ultraviolet light, so it is important to minimize exposure to direct sunlight or strong ultraviolet light sources. Long-term exposure to UV light will degrade the film and affect its printing properties. Whenever possible, store movies in a dark or low-light environment.

6. Rotate stock: If you have multiple rolls of UV DTF film, please rotate stock to ensure freshness and quality. First, use the oldest rolls to prevent long-term storage and potential deterioration of membrane performance.

7. Follow manufacturer's recommendations: Each UV DTF film supplier may have specific handling and storage recommendations. It is very important to read and follow the manufacturer's instructions attached to the film. They can provide additional guidance on handling, storage temperature, humidity levels and shelf life.

8. Regular inspection and monitoring: Regularly inspect the UV DTF film for any signs of damage such as scratches, creases or discoloration. If any damage is found, it is best to discard the affected part or replace the membrane. Monitor storage conditions and make adjustments as necessary to maintain the recommended environment.

By following these tips, you can ensure proper handling and storage of UV DTF film, which will help maintain its quality, extend its shelf life, and optimize its performance during printing.