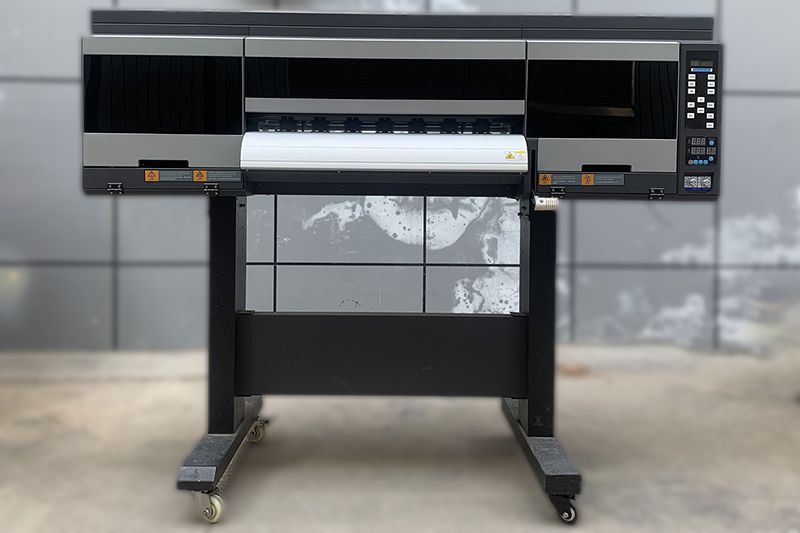

The printing industry is continually evolving, and the recent advancements in DTF printing technology are a testament to this progress. Among the latest innovations is the KTM-A08 Neon 9-color Four-head DTF Printer, a state-of-the-art machine designed to meet the demands of modern textile printing. This DTF Printer brings together cutting-edge technology, robust construction, and user-friendly features to deliver outstanding results across a wide range of applications.

The Key Features of the KTM-A08 DTF Printer

At the heart of the KTM-A08 DTF Printer lies the powerful I3200A1 printheads. This printer is equipped with four of these high-performance printheads, arranged to ensure optimal ink delivery and minimize the risk of clogging. This setup is essential for maintaining consistent print quality, even during long printing runs. The ability to produce vibrant neon colors further enhances the appeal of the KTM-A08, making it an ideal choice for designs that require bright, eye-catching visuals.

The KTM-A08 DTF Printer is designed with flexibility in mind, offering multiple print speed options to suit various production needs. It can operate at three different speeds: 3Pass at 50㎡/h, 6Pass at 31.4㎡/h, and 8Pass at 20㎡/h. This range of speeds allows users to balance between productivity and print quality, depending on the specific requirements of each project. For high-volume jobs, the 3Pass setting provides rapid output, while the 6Pass and 8Pass settings offer higher resolution for detailed, intricate designs.

Precision is a crucial factor in textile printing, and the KTM-A08 DTF Printer excels in this area. It offers three levels of printing accuracy: 720720dpi, 7201800dpi, and 7202400dpi. These options ensure that every detail of your design is captured with clarity and precision, whether you are working on complex patterns or simple logos. The ability to adjust the resolution based on the specific needs of each project enhances the versatility of this DTF Printer, making it suitable for a wide range of applications.

With a maximum printing width of 620mm, the KTM-A08 DTF Printer can handle various fabric sizes, making it ideal for both small-scale custom designs and larger commercial projects. Despite its compact footprint (measuring 1800mm in length, 760mm in width, and 1420mm in height), this printer is built to last, weighing in at 195kg. Its sturdy construction ensures stability during operation, which is essential for maintaining print quality.

Advanced Heating System

The KTM-A08 DTF Printer is equipped with an advanced three-section heating system, designed to ensure optimal print results. This system includes a pre-heater, a printing bed heater, and a rear heater, all of which can be adjusted between 30℃ and 65℃. The precise control over these heating elements is crucial for achieving the best possible ink adhesion and drying, particularly when working with different types of fabrics. Proper heating not only enhances print quality but also prevents common issues such as smudging or uneven drying.

The KTM-A08 DTF Printer uses textile pigment ink in eight colors: cyan, magenta, yellow, black, and white (C/M/Y/K/W). This ink configuration provides a wide color gamut, allowing for the reproduction of vivid and accurate colors on various fabrics. Whether printing on cotton, polyester, or other materials, the KTM-A08 DTF Printer consistently delivers high-quality results.

Power Efficiency and User-Friendliness

Energy efficiency is another key feature of the KTM-A08 DTF Printer. The printer itself operates at 350W, while the powder dryer requires 8500W. This balance between power consumption and output ensures that the printer can handle demanding production schedules without significantly increasing operational costs. This efficiency is particularly important for businesses looking to minimize their environmental footprint while maintaining high production standards.

The KTM-A08 DTF Printer is also designed with ease of use in mind. It features a straightforward interface that makes it accessible to both novice and experienced operators. The printer supports both Chinese and English languages, making it suitable for use in a global market. The ironing temperature ranges from 160-170℃, with options for both cold and hot peel, offering further flexibility depending on the specific requirements of each project.

In conclusion, the KTM-A08 DTF Printer is more than just a piece of equipment; it is a significant step forward in the evolution of fabric printing technology. Its advanced features, robust construction, and user-friendly design make it an invaluable asset for any textile printing operation. Whether you are looking to produce vibrant neon designs or intricate multi-color prints, the KTM-A08 DTF Printer is equipped to meet your needs, setting new standards for the industry and paving the way for future innovations in DTF printing.