One of the notable advantages of UV printing is that it produces waterproof and scratch-resistant prints. Here's how UV printing achieves these properties:

1. UV Ink Formulation: UV inks used in UV printing are specifically formulated to provide excellent durability and resistance to water and scratches. These inks contain additives and binders that enhance the ink's ability to withstand exposure to moisture and physical abrasion.

2. Instant Curing: UV printing utilizes UV lamps that emit high-intensity UV light to instantly cure or dry the UV ink. This rapid curing process creates a hard and durable surface on the printed material, making it less susceptible to damage from water and scratches.

3. Chemical Resistance: UV inks used in UV printing are designed to resist the effects of chemicals, including water-based and solvent-based substances. This chemical resistance enables the prints to maintain their quality and appearance even when exposed to liquids or cleaning agents.

4. Strong Adhesion: UV inks form a strong bond with the substrate during the curing process. This strong adhesion ensures that the ink remains firmly attached to the surface, reducing the likelihood of scratches or peeling.

5. UV Varnish or Lamination: To further enhance the waterproof and scratch-resistant properties of UV prints, a UV varnish or laminate can be applied as a protective layer. These coatings provide an additional barrier against moisture and physical damage, increasing the longevity and durability of the prints.

6. Outdoor Durability: UV printing is well-suited for outdoor applications due to its waterproof and scratch-resistant properties. UV prints can withstand exposure to various weather conditions, including rain, sun, and wind, without significant degradation or loss of quality.

The combination of UV ink formulation, instant curing, chemical resistance, strong adhesion, and the option to apply protective coatings makes UV printing an ideal choice for producing waterproof and scratch-resistant prints. These properties ensure that the prints maintain their quality, vibrancy, and durability, even in challenging environments or high-touch applications.

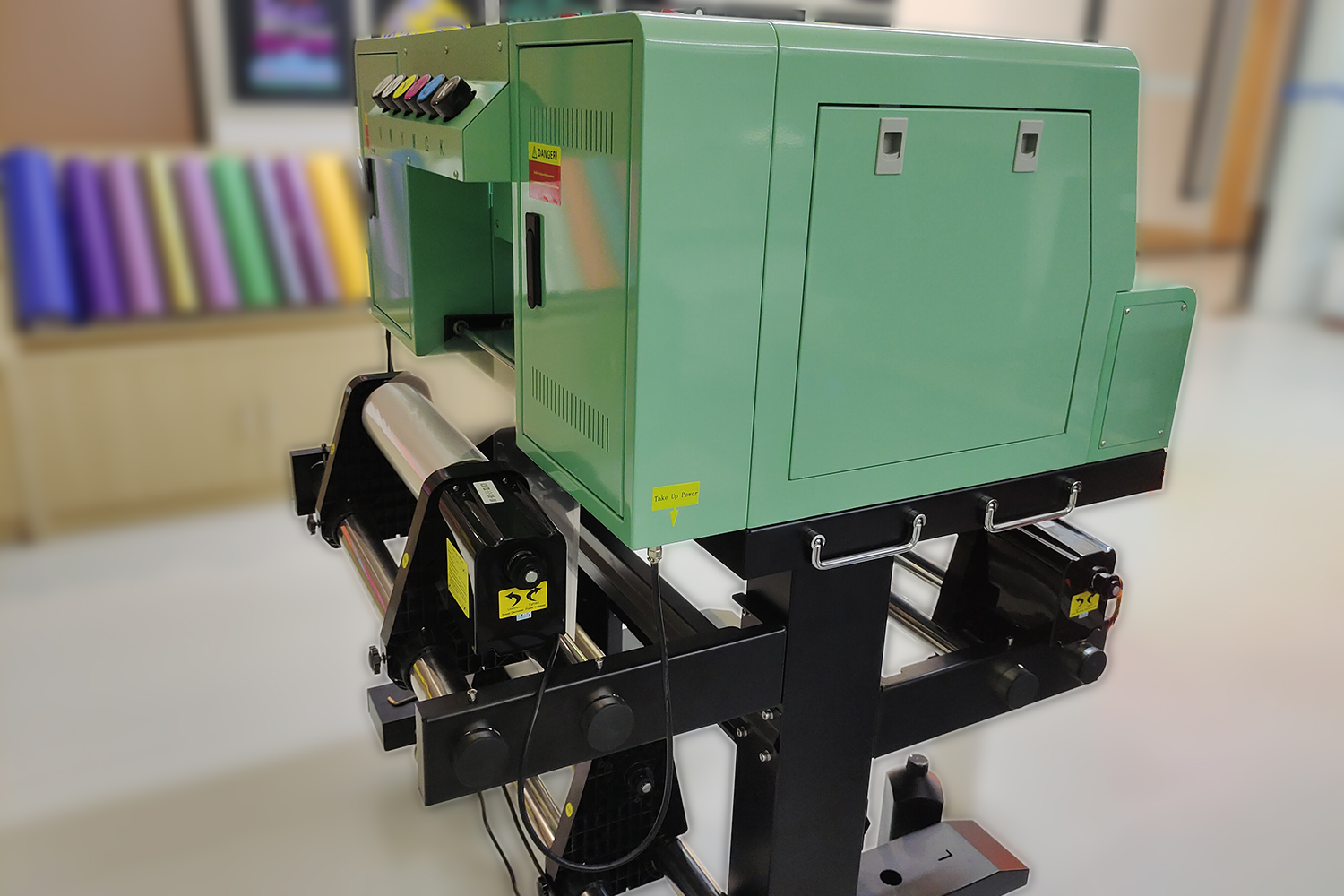

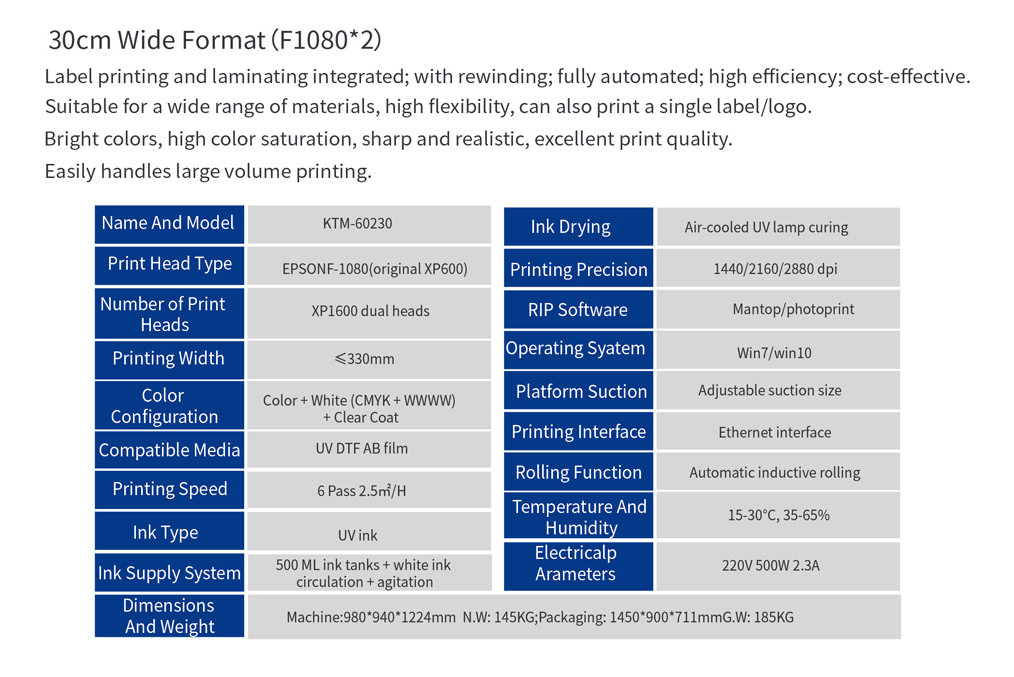

kenteer has launched UV Printers for customers . If you have any needs, you can contact us for a quote.