The Kenteer KTM-A57 is a groundbreaking UV printer designed to redefine versatility in the printing industry. This all-in-one solution seamlessly integrates plate, roll, and cylinder printing capabilities, offering businesses a powerful tool to expand their product offerings and streamline production processes. With its advanced features and cutting-edge technology, the KTM-A57 UV printer delivers exceptional print quality and productivity across a wide range of materials.

This innovative UV printer utilizes four Epson I3200HD micro-voltage printheads, renowned for their precision and longevity. These printheads, combined with the vibrant UV ink set (CMYK ORGB W V), deliver stunningly detailed prints with vibrant colors and exceptional clarity. Whether printing on rigid plates, flexible rolls, or curved cylinders, the KTM-A57 UV printer maintains consistent quality and precision, ensuring professional results every time.

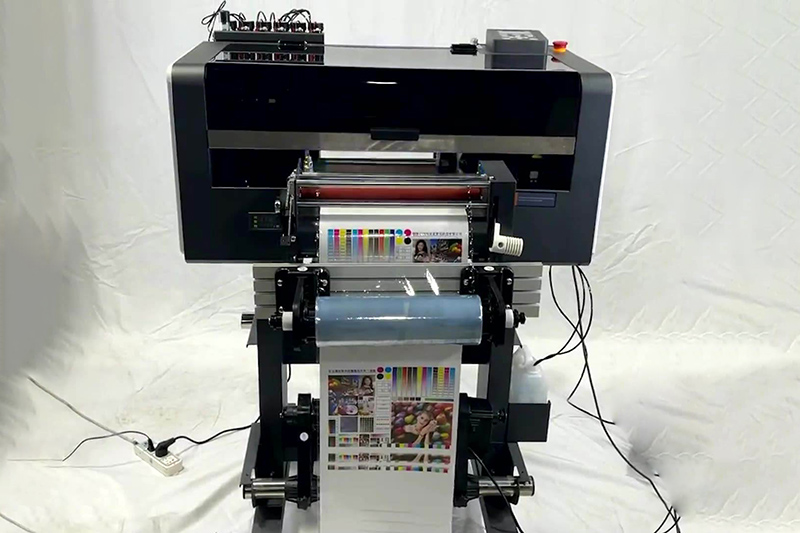

One of the key differentiators of the KTM-A57 UV printer is its adaptability. The three-station printing system allows for seamless transitions between plate, roll, and cylinder printing without the need for time-consuming reconfigurations. The plate station caters to rigid substrates, the roller station handles flexible materials with ease, and the cylinder station empowers users to print directly onto cylindrical objects. This adaptability opens up a world of creative possibilities, enabling businesses to produce a diverse range of printed products, including signage, promotional items, packaging, and customized industrial components.

The KTM-A57 UV printer prioritizes efficiency and ease of use. The Hosonsoft master software, coupled with the intuitive ONYX NeoStampa PP image processing software, provides a streamlined workflow from design to print. The dual Gigabit network ports ensure rapid data transfer, minimizing downtime and maximizing productivity. Furthermore, the automated Z-axis height measurement ensures precise printhead positioning for optimal print quality on varying substrate thicknesses. The one-button automatic cleaning system for nozzles simplifies maintenance and ensures consistent printhead performance. This feature contributes significantly to minimizing downtime and maximizing the lifespan of the printheads, a crucial aspect for any UV printer investment.

Beyond its core functionalities, the KTM-A57 UV printer boasts several advanced features designed to enhance both productivity and precision. The AI visual scanning positioning system ensures accurate registration and alignment, crucial for complex designs and multi-panel prints. This technology minimizes errors and material waste, contributing to a more efficient and cost-effective printing process. For businesses seeking high-volume output, the KTM-A57 UV printer offers impressive print speeds. In production mode, it can achieve speeds of up to 15 m²/h, ensuring fast turnaround times even for large print runs. The UV printer's versatility extends beyond its multi-material handling capabilities. The range of print modes, from draft to high-quality, allows users to optimize print settings for specific applications, balancing speed and detail as needed.

Built for demanding production environments, the KTM-A57 UV printer is engineered for reliability and durability. The robust construction ensures stable performance, while the advanced features, such as the siphon ink supply and automatic printhead cleaning system, contribute to long-term reliability. The KTM-A57 UV printer is a powerful and versatile tool that empowers businesses to explore new creative avenues and expand their product offerings. Its ability to handle a wide range of materials, coupled with its advanced features and user-friendly interface, makes it a compelling choice for businesses seeking a high-performance UV printer solution. This UV printer is a testament to Kenteer’s commitment to innovation and quality, offering a comprehensive solution for businesses seeking to elevate their printing capabilities. Whether you are a sign maker, a packaging specialist, or an industrial manufacturer, the KTM-A57 UV printer provides the tools you need to succeed in today's competitive market. The Kenteer KTM-A57 represents a significant advancement in UV printer technology, offering a compelling combination of versatility, performance, and ease of use. It is a true all-in-one solution, poised to revolutionize the way businesses approach multi-material printing. This UV printer is a valuable asset for any company seeking to expand its capabilities and unlock new creative possibilities.