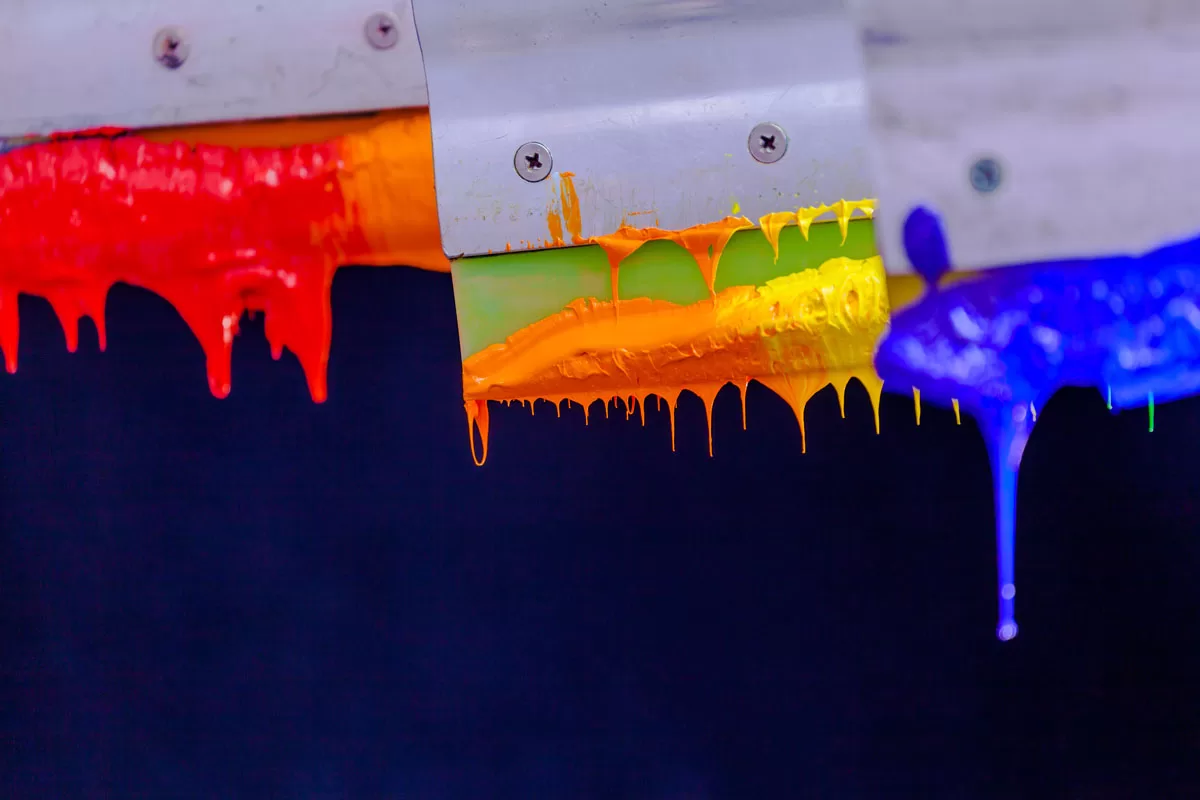

Plastisol ink Y-RG series color is an excellent choice for screen printing enthusiasts and professionals alike. This versatile ink not only provides vibrant and long-lasting designs but also offers various benefits over other types of inks. In this article, we will delve deeper into the world of plastisol ink Y-RG series color, highlighting its advantages, applications, and tips for achieving outstanding results.

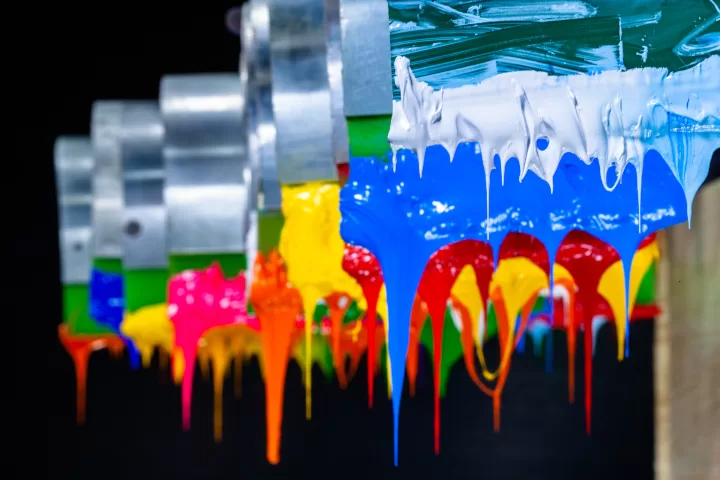

White Plastisol Ink Silk Textile Screen Printing For Print Machine

I. Understanding Plastisol Ink Y-RG Series Color:

Plastisol ink Y-RG series color is a specialty ink mainly used in the screen printing industry. It is known for its rich and vibrant colors, allowing artists and printers to create eye-catching designs. The Y-RG series color is specifically formulated to provide a wide range of shades in the yellow and red-green spectrum, making it perfect for designs that require warm and lively colors.

II. Benefits of Using Plastisol Ink Y-RG Series Color:

- Vibrant and Durable: Plastisol ink Y-RG series color offers exceptional color vibrancy, ensuring that your designs pop off the fabric. Moreover, it provides excellent washability and durability, allowing your prints to withstand multiple washes without fading or cracking.

- Easy to Use: One of the significant advantages of plastisol ink Y-RG series color is its simplicity. It is easy to work with, especially for beginners. Its thick consistency ensures precise placement while printing, reducing the chances of smudging or bleeding.

- Versatility: Plastisol ink Y-RG series color can be used on a wide range of fabrics, including cotton, polyester, and blends. This versatility makes it a popular choice for apparel printing, allowing you to create stunning designs on t-shirts, hoodies, and other garment types.

III. Applications of Plastisol Ink Y-RG Series Color:

- Fashion Industry: Plastisol ink Y-RG series color is widely used in the fashion industry due to its ability to produce vivid and unique designs. From trendy t-shirts to stylish sweatshirts, this ink can help create garments that truly stand out.

- Sports Apparel: Whether it's team jerseys, workout gear, or fan merchandise, plastisol ink Y-RG series color can capture the spirit and energy of sports. Its durability on various fabrics ensures that the prints remain intact during intense physical activities.

- Promotional Merchandise: Customized promotional items play a vital role in brand promotion. Plastisol ink Y-RG series color allows businesses to print their logos and designs on products like caps, bags, and accessories, attracting attention and leaving a lasting impression.

IV. Tips for Achieving Outstanding Results:

- Proper Ink Mixing: To obtain the desired shade, it's important to mix plastisol ink Y-RG series color with precision. Experiment with different ratios to achieve the perfect color for your design.

- Test Prints: Before printing in bulk, always perform test prints to ensure color accuracy and quality. This allows you to make any necessary adjustments before moving forward.

- Curing Process: Plastisol ink Y-RG series color requires proper curing to achieve optimal results. Follow the manufacturer's instructions for temperature and time settings to ensure a well-bonded and durable print.

Plastisol ink Y-RG series color is a valuable tool for screen printers looking to create vibrant and long-lasting designs. With its exceptional color vibrancy, ease of use, and versatility, it has become a preferred choice in the industry. Whether you're in the fashion, sports, or promotional field, this ink can help you achieve outstanding results. Remember to experiment, test, and follow proper curing techniques to ensure the best possible prints. Embrace the possibilities of plastisol ink Y-RG series color and elevate your screen printing game!