Creating custom apparel with inkjet transfer paper and a heat press is a cost-effective and easy way to produce high-quality custom apparel. Here are the steps to create custom apparel with inkjet transfer paper and a heat press:

1. Design Your Artwork

The first step to creating custom apparel is to design your artwork. You can use software such as Adobe Illustrator or Canva to create your design. Make sure to size your design according to the size of the garment you plan to transfer it onto.

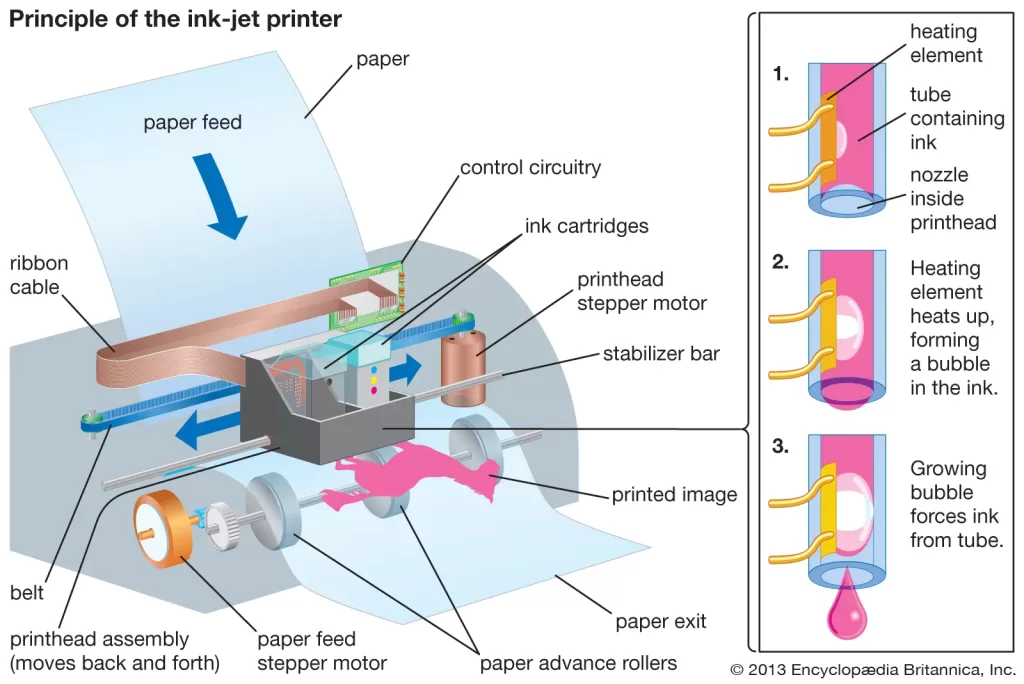

2. Print Your Design

Once you've designed your artwork, it's time to print it onto the inkjet transfer paper. Make sure to mirror your design before printing it onto the transfer paper. This is because the image will be flipped when you transfer it onto the garment.

3. Cut Your Design

After printing your design, it's time to cut it out. Use a pair of scissors or a cutting machine to carefully cut around the edges of your design, leaving a small border around the edges.

4. Preheat Your Heat Press

Before transferring your design onto the garment, preheat your heat press to the recommended temperature and time settings for your transfer paper.

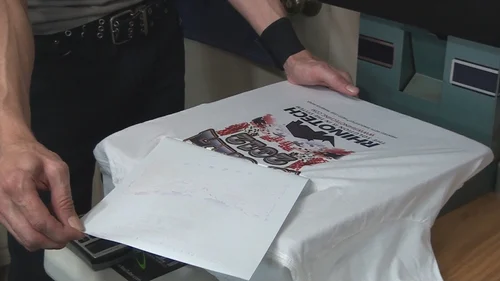

5. Position Your Transfer

Place your transfer paper onto the garment with the design facing down. Make sure to position it correctly before pressing it.

6. Press Your Transfer

Once your transfer paper is positioned correctly, it's time to press it. Place a sheet of parchment paper over the transfer paper and use the heat press to press down on the transfer paper for the recommended time and temperature settings.

7. Peel Off the Transfer Paper

After pressing your transfer paper, carefully peel off the transfer paper while it's still warm. This will reveal your design on the garment.

8. Enjoy Your Custom Apparel

Your custom apparel is now complete! Enjoy wearing it or selling it to your customers.

In conclusion, creating custom apparel with inkjet transfer paper and a heat press is an easy and cost-effective way to produce high-quality custom apparel. By following these simple steps, you can create custom apparel that looks professional and polished. So why not give it a try and see how it can benefit your business today?