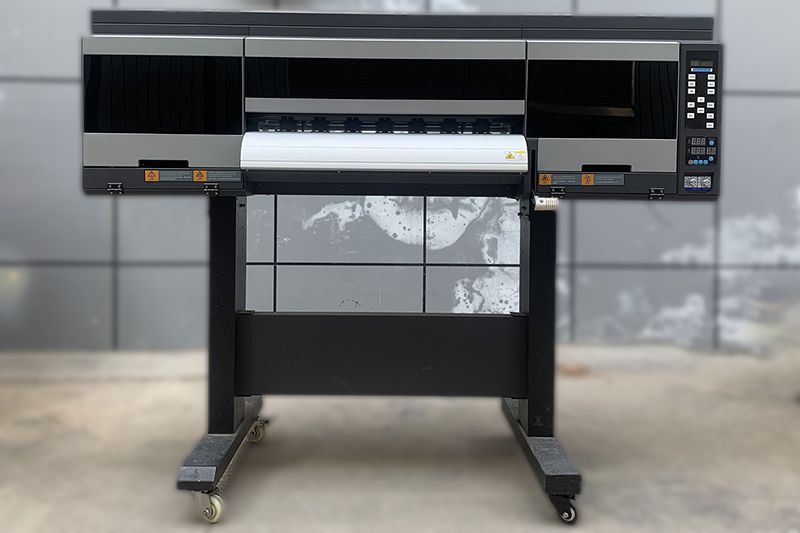

The Kenteer KTM-A09 is a cutting-edge digital textile printer specifically designed for Direct-to-Film (DTF) printing. This innovative technology has revolutionized the garment decoration industry by offering a versatile and high-quality method of transferring designs onto a wide range of fabrics. In this article, we will delve into the intricate workings of the KTM-A09, exploring its components and the DTF printing process.

DTF printing is a relatively new technique that involves transferring a printed image onto a special film using pigment ink. The film is then coated with a layer of adhesive powder and cured, creating a flexible transfer sheet. This transfer sheet can be heat pressed onto various fabrics, resulting in vibrant and durable prints.

Key Components of the KTM-A09

Printheads: The KTM-A09 is equipped with dual I3200A1 HD printheads, renowned for their precision and high-speed printing capabilities. These printheads eject tiny droplets of pigment ink onto the film, creating intricate and detailed designs.

Heating System: The printer features a three-stage heating system, including a pre-heater, printing bed heater, and rear heater. This system ensures optimal curing of the adhesive powder, promoting strong adhesion to the fabric.

Printing Software: The KTM-A09 is compatible with industry-standard software such as Maitop 6.1, RIIN, and PP, allowing for seamless integration into existing workflows.

Ink System: The printer utilizes textile pigment ink, which is specifically formulated for DTF printing. These inks offer excellent color gamut, durability, and wash fastness.

The DTF Printing Process

1. Image Preparation: The desired design is created using graphic design software and prepared for printing.

2. Film Feeding: A special PET film is loaded into the printer.

3. Ink Deposition: The printheads deposit pigment ink onto the film, creating a mirror image of the design.

4. Powder Coating: The printed film passes through a powder shaker, which evenly coats the ink with adhesive powder.

5. Curing: The film is then cured in an oven, fusing the powder to the ink.

6. Weeding: Any excess powder is removed from the film.

7. Transfer: The transfer sheet is placed onto the fabric and heat pressed, transferring the design.

The Kenteer KTM-A09 DTF Printer is a powerful and versatile tool for businesses looking to offer custom printed garments and products. By understanding the DTF printing process and the key components of the KTM-A09, users can maximize the capabilities of this innovative machine. As DTF printing continues to evolve, it is poised to become an increasingly popular method of textile decoration.

If you have product purchasing needs, you can contact us.