The KTM-1904, a 4-head high-speed sublimation printer, represents a significant leap in Direct-to-Film printing technology. To understand its advancements, we must first delve into the historical context of textile printing and the evolution of DTF technology.

Early Textile Printing Methods

Traditional Methods For centuries, textile printing relied on techniques like block printing, screen printing, and roller printing. These methods, while effective, were often labor-intensive, time-consuming, and limited in design complexity and color options.

Analog Printing Evolution The advent of analog printing technologies like dye-sublimation and inkjet printing offered improvements in efficiency and design possibilities. However, these methods still presented challenges in terms of cost, material compatibility, and environmental impact.

The Emergence of DTF Printing

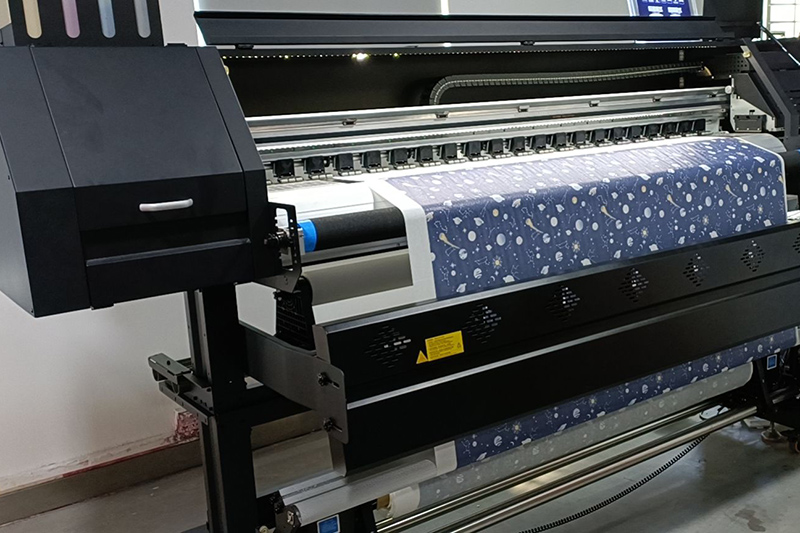

Direct-to-Film printing emerged as a game-changer in the textile printing industry. This digital printing technology involves printing designs onto a special film, which is then transferred onto fabric using heat and pressure. DTF offered several advantages over traditional methods:

Versatility DTF printing is compatible with a wide range of fabrics, including cotton, polyester, blends, and even dark-colored materials.

Design Flexibility It allows for intricate designs, full-color printing, and photographic images, expanding creative possibilities for textile printing.

Efficiency and Speed DTF printing streamlines the production process, enabling faster turnaround times and on-demand printing capabilities.

Reduced Environmental Impact Compared to traditional methods, DTF printing often uses less water and generates less waste.

Technological Advancements Leading to the KTM-1904

The development of the KTM-1904 is a culmination of several key technological advancements in DTF printing:

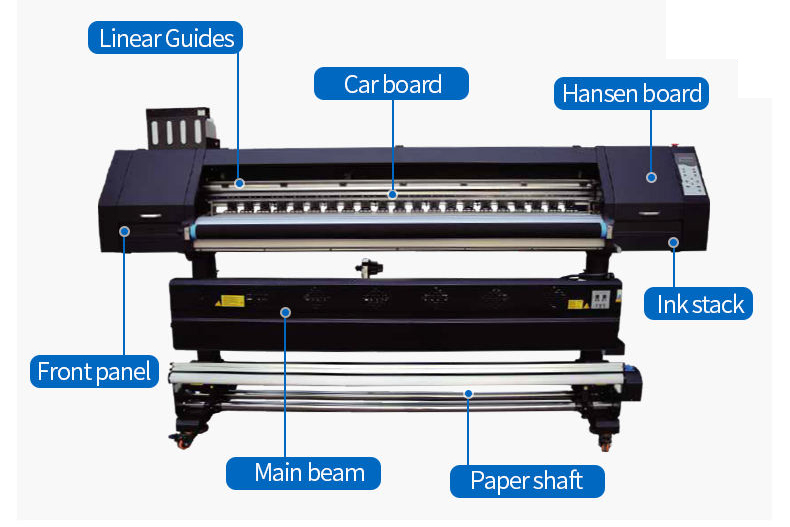

Printhead Technology The KTM-1904 boasts 14 high-precision 13200-A1 printheads, enabling high-resolution printing with vibrant colors and sharp details. Advancements in printhead technology have led to increased print speeds and improved ink droplet placement accuracy.

Ink Systems The printer features an exclusive all-aluminum ink stack, designed for reliability and durability. Developments in ink formulations have resulted in inks with better color gamut, adhesion, and wash fastness.

Heating and Drying Systems The KTM-1904 incorporates an auto constant temperature drying system, ensuring uniform heat distribution for optimal ink absorption and print quality. Advancements in heating technology have led to more efficient and consistent drying processes.

Software and Automation The printer is compatible with RIP software like Maintop and PhotoPrint, allowing for seamless integration with design software and color management tools. Automation features like the lack of ink and paper alarm systems enhance user convenience and production efficiency.

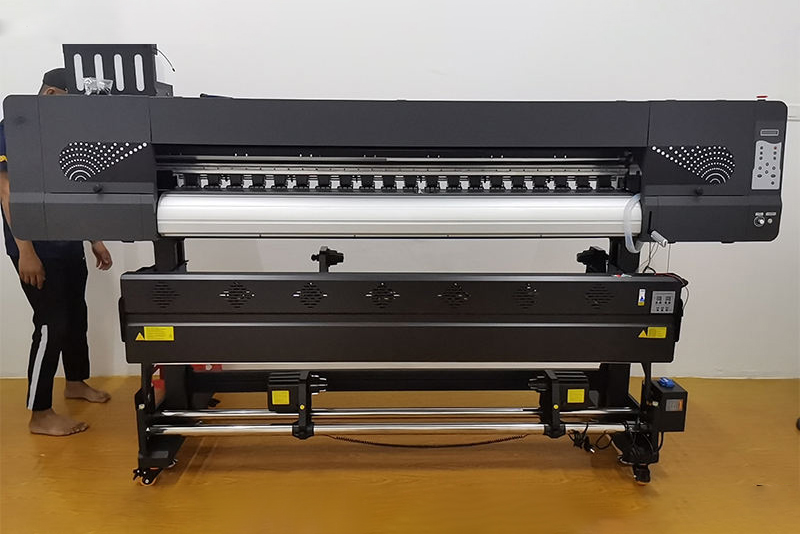

The KTM-1904: A Pinnacle of DTF Printing Technology

The KTM-1904 represents a significant step forward in DTF printing technology. Its combination of high-speed printing, advanced printheads, reliable ink systems, and intelligent automation features makes it a powerful tool for textile printing businesses.

Impact on the Textile Industry

The KTM-1904 and similar advancements in DTF printing technology have revolutionized the textile industry:

Increased Customization DTF printing enables personalized and on-demand production, catering to individual customer preferences and market trends.

Expanded Applications DTF printing has expanded beyond traditional garment printing to include home décor, accessories, and promotional items.

Enhanced Efficiency and Productivity The speed and automation of DTF printers like the KTM-1904 have significantly improved production efficiency and reduced labor costs.

New Business Opportunities DTF printing has opened doors for new businesses and entrepreneurs in the textile printing sector.

Looking Ahead

As DTF printing technology continues to evolve, we can expect further advancements in print speed, resolution, color accuracy, and material compatibility. The future of DTF printing is bright, with printers like the KTM-1904 paving the way for a more efficient, versatile, and sustainable textile printing industry.

If you have product purchasing needs, you can contact us.