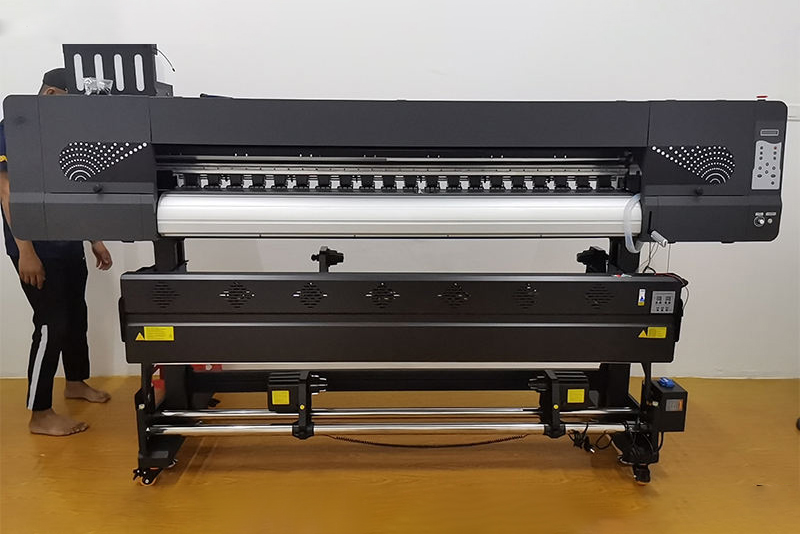

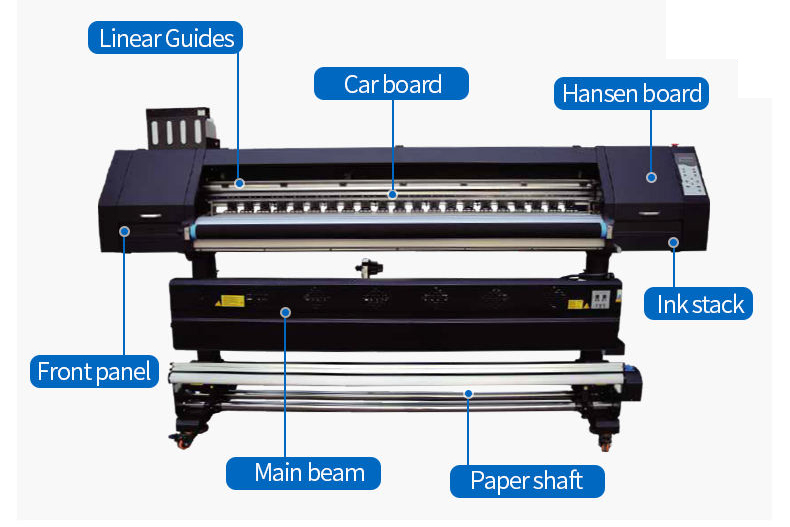

The KTM-1904 DTF (Direct-to-Film) printer, with its impressive specifications and innovative features, is poised to revolutionize the textile printing industry. This high-speed, 4-head printer boasts a 1.9m printing width and utilizes 14pcs of 13200-A1 printheads, enabling it to handle large-scale production with ease. Its advanced technology and user-friendly design make it suitable for a wide range of applications, catering to both established businesses and aspiring entrepreneurs.

Versatility Across Fabrics and Products

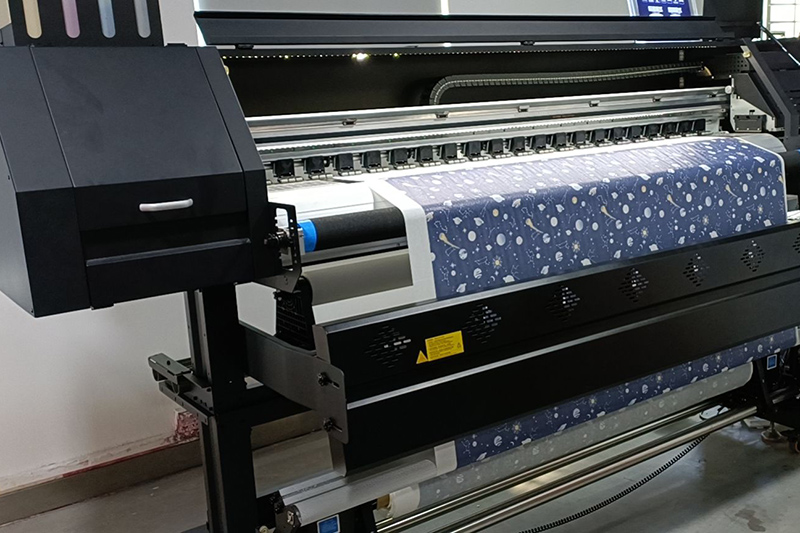

One of the key strengths of the KTM-1904 lies in its versatility. Unlike traditional printing methods that are often limited to specific fabric types, DTF printing allows for vibrant, full-color designs on a wide variety of materials, including:

Cotton From t-shirts and hoodies to tote bags and home textiles, the KTM-1904 excels at printing on cotton, offering excellent color vibrancy and wash durability.

Polyester The printer's ability to handle polyester opens doors to sportswear, activewear, and outdoor apparel printing, where performance and longevity are crucial.

Blends Whether it's cotton-polyester blends or other mixed fabrics, the KTM-1904 ensures consistent, high-quality results, expanding the possibilities for garment decoration.

Leather Adding a touch of personalization to leather goods like bags, wallets, and jackets becomes effortless with the KTM-1904's capabilities.

Canvas Artists and businesses can leverage the printer to create stunning prints on canvas for art reproductions, personalized gifts, and promotional items.

Efficiency and Productivity

The KTM-1904 is designed for efficiency and high-volume production. Its auto constant temperature drying system ensures uniform heating, leading to optimal ink absorption and delicate, full-color prints. The large capacity ink system with an intelligent alarm function minimizes downtime by providing a continuous ink supply. Additionally, the lack of paper alarm system further streamlines the printing process, ensuring smooth and uninterrupted operation.

Personalized Customization

The KTM-1904 caters to the growing demand for personalized products. Its compatibility with braid and pyrograph industries allows for unique customization options, enabling businesses to offer bespoke designs and cater to individual customer preferences. This opens doors to new market opportunities and enhances brand value through personalized offerings.

Applications Across Industries

The versatility and efficiency of the KTM-1904 make it a valuable asset across various industries:

Fashion and Apparel From established clothing brands to independent designers, the KTM-1904 empowers businesses to create eye-catching garments with intricate designs and vibrant colors.

Promotional Products Businesses can leverage the printer to produce personalized promotional items like t-shirts, bags, and caps, enhancing brand visibility and marketing efforts.

Home Decor The KTM-1904 allows for the creation of custom-printed home textiles like cushion covers, curtains, and tablecloths, adding a personal touch to interior spaces.

Art and Photography Artists and photographers can utilize the printer to reproduce their work on canvas or other materials, offering high-quality prints for sale or exhibition.

Ease of Use and Maintenance

Despite its advanced features, the KTM-1904 remains user-friendly. The intuitive interface and intelligent alarm systems simplify operation, while the self-developed all-aluminum ink stack ensures reliability and durability. The printer's robust construction and accessible design facilitate easy maintenance, minimizing downtime and maximizing productivity.

All in all, the KTM-1904 DTF printer presents a powerful tool for businesses and individuals seeking to explore the vast potential of textile printing. Its versatility, efficiency, and user-friendly design make it an ideal choice for a wide range of applications, pushing the boundaries of creativity and customization in the printing industry.

If you have product purchasing needs, you can contact us.