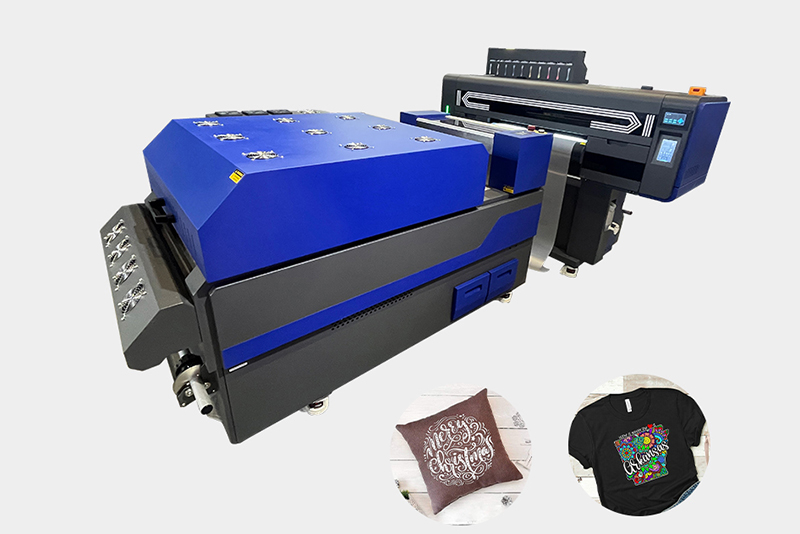

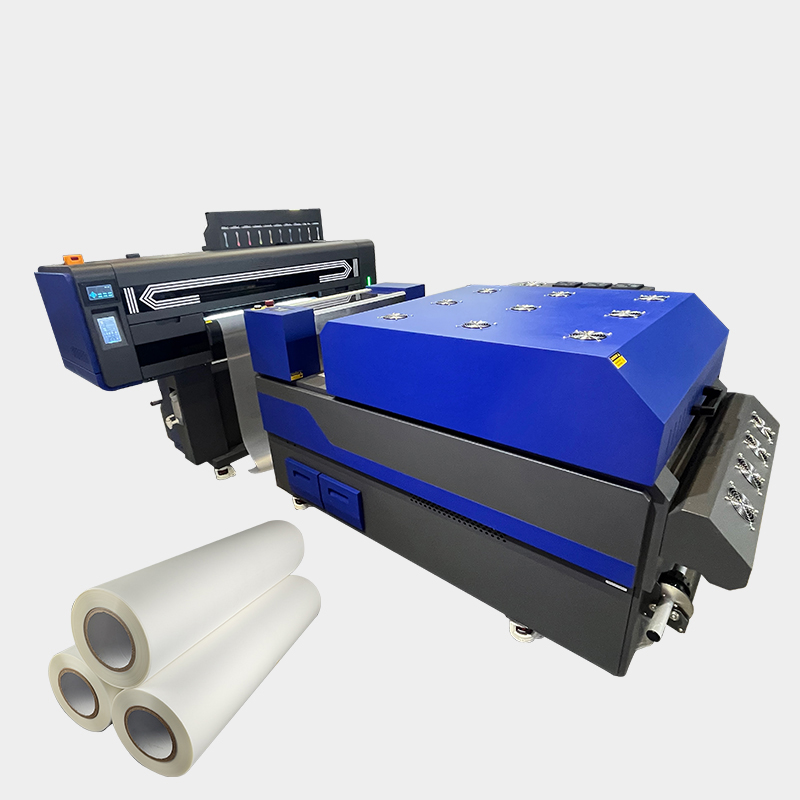

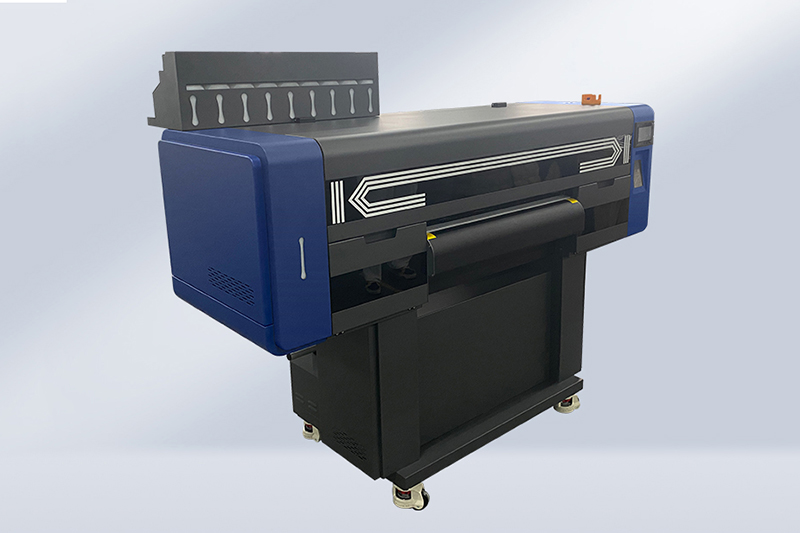

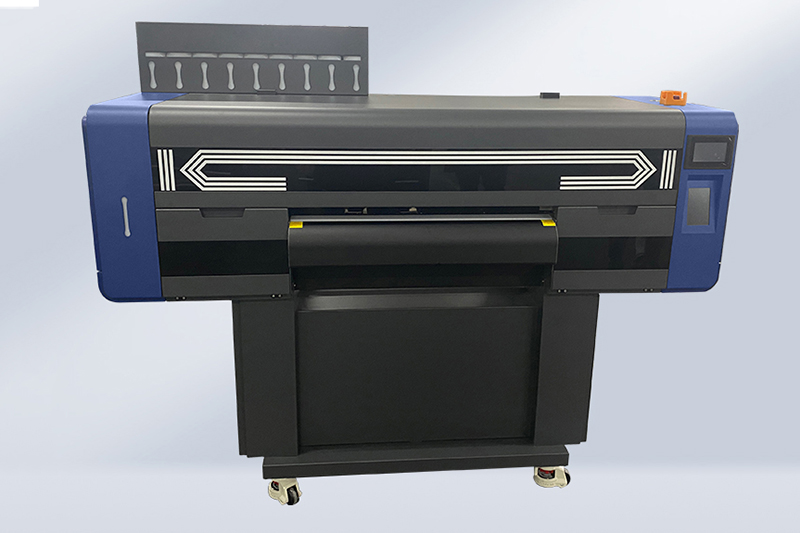

The Kenteer KTM-A41 DTF Printer is a high-quality, wide-format printer that is perfect for a variety of printing applications, including t-shirts, hats, bags, and more. It uses DTF (Direct to Film) technology to print vibrant, durable designs onto a variety of materials.

Features

Four Epson I3200-A1 print heads for fast, high-quality printing

Intelligent temperature control for consistent results

Moisturizing and cleaning function to prevent clogging

Upgraded damper heating to improve ink fluency and stable output

Nozzle-Qut compensation for accurate printing

Auto in-Line Moisturizing to prevent clogging

Imported high-quality THK guide for stable printing with low noise

Benefits

High-quality printing: The Kenteer KTM-A41 DTF Printer produces high-quality prints with vibrant colors and sharp details.

Durability: DTF prints are durable and can withstand washing and wear.

Versatility: The printer can print on a variety of materials, including t-shirts, hats, bags, and more.

Ease of use: The printer is easy to set up and use, even for beginners.

Affordability: The printer is affordable for small businesses and home users.

Who Should Buy the Kenteer KTM-A41 DTF Printer?

The Kenteer KTM-A41 DTF Printer is a great option for a variety of businesses and individuals, including:

T-shirt printers: The printer is perfect for printing custom t-shirts for businesses, schools, and events.

Hat printers: The printer can print on a variety of hat styles, including baseball caps, beanies, and visors.

Bag printers: The printer can print on a variety of bags, including tote bags, backpacks, and duffel bags.

Sign and banner printers: The printer can print on a variety of signs and banners, including vinyl banners, fabric banners, and mesh banners.

Home users: The printer is also a great option for home users who want to print custom designs on their own clothing and accessories.

How to Choose the Right DTF Printer

When choosing a DTF printer, there are a few factors to consider, including:

Print quality: The quality of the printer's output is the most important factor to consider. Make sure to choose a printer that can produce high-quality prints with vibrant colors and sharp details.

Print speed: The print speed of the printer is also important, especially if you need to print a high volume of items. Choose a printer that can print quickly and efficiently.

Print size: The print size of the printer is another important factor to consider. Make sure to choose a printer that can print the size of items that you need to print.

Price: The price of the printer is also an important factor to consider. Set a budget and choose a printer that fits within your budget.

Additional Tips

Make sure to buy DTF ink and film from a reputable supplier.

Use a high-quality heat press to apply the DTF transfers to your items.

Wash your items according to the care instructions.

The Kenteer KTM-A41 DTF Printeris a high-quality, versatile, and affordable printer that is perfect for a variety of printing applications. If you are looking for a DTF printer, the Kenteer KTM-A41 is a great option to consider.

If you have product purchasing needs, you can contact us.