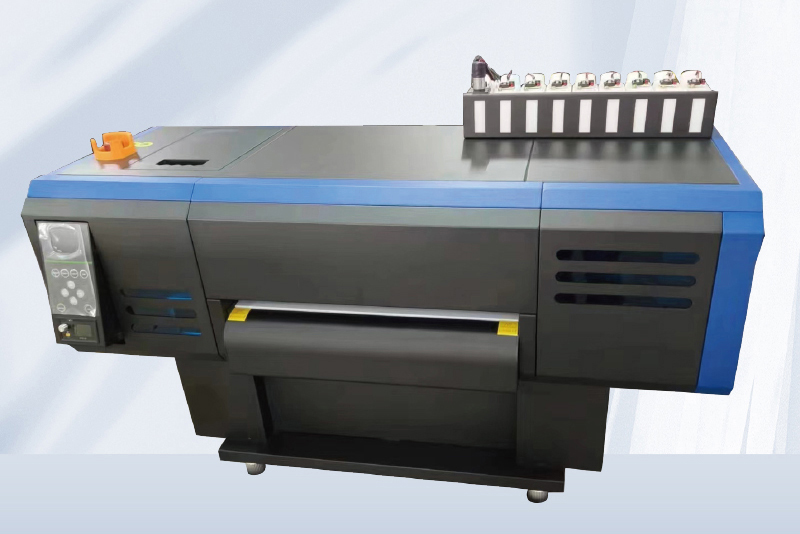

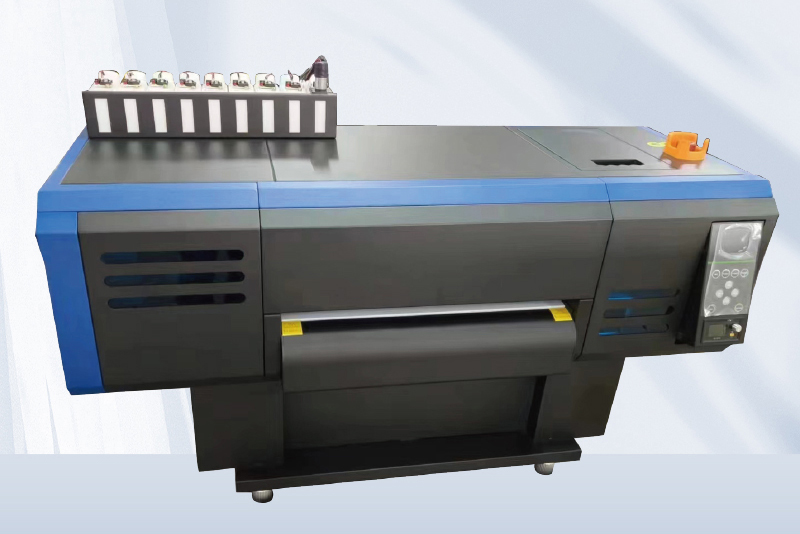

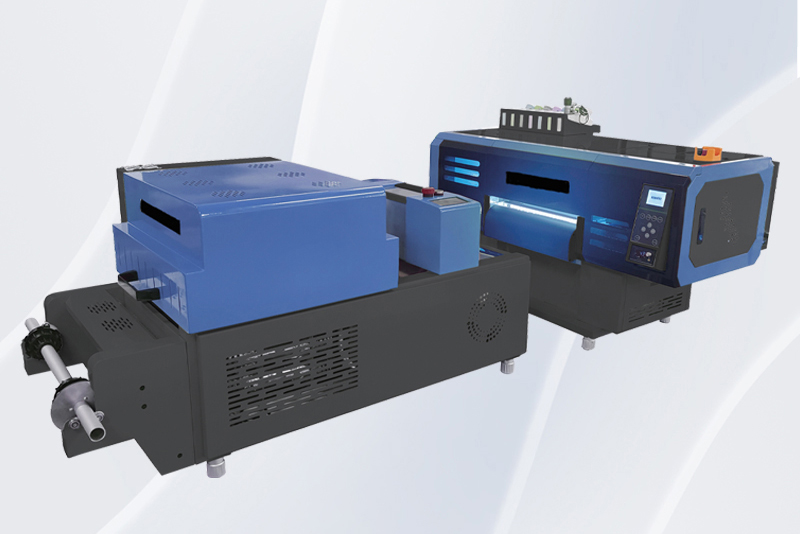

The KTM-A45 DTF Printer is a versatile and powerful machine that utilizes Direct-to-Film (DTF) technology to produce high-quality prints on a variety of substrates. To ensure the longevity and optimal performance of your KTM-A45 DTF Printer, regular maintenance is crucial. This comprehensive guide will provide you with detailed instructions and recommendations for maintaining your printer, ensuring consistent and exceptional printing results.

Daily Maintenance

1. Shake the White Ink Cartridge: White ink is prone to pigment settling, so shaking the cartridge vigorously for about 10 seconds before each use is essential to prevent clogs and ensure even whiteness in your prints.

2. Printhead Cleaning: Regular printhead cleaning is paramount to maintaining optimal ink flow and preventing nozzle clogs. Utilize the printer's built-in cleaning function or manually clean the printhead using DTF cleaning solution and lint-free swabs.

3. Nozzle Checks: Before starting any printing jobs, perform nozzle checks to identify and address any potential nozzle blockages. This proactive approach ensures consistent print quality and prevents wasted ink.

Periodic Maintenance

1. Ink Cartridge Replacement: Replace ink cartridges as needed, ensuring you use genuine Kenteer ink cartridges to maintain print quality and printer health.

2. Wiper Blade Cleaning: The wiper blade plays a crucial role in keeping the printhead clean. Clean the wiper blade regularly using DTF cleaning solution and lint-free swabs to prevent ink buildup and ensure smooth printhead movement.

3. Capping Station Cleaning: The capping station houses the printhead when not in use, maintaining its moisture and preventing it from drying out. Clean the capping station periodically using DTF cleaning solution and lint-free swabs to remove any dried ink residue.

4. Internal Component Cleaning: Over time, ink can accumulate inside the printer, potentially causing issues. Regularly clean internal components, such as the ink tubes and pump, using DTF cleaning solution and lint-free swabs to maintain optimal performance.

Material and Environment Considerations

1. Proper Ink and Film Storage: Store DTF ink and film in a cool, dry place away from direct sunlight and extreme temperatures. Improper storage can affect ink viscosity and film quality.

2. Maintain a Stable Environment: Operate the printer in an environment with a consistent temperature between 20°C and 28°C and humidity levels between 65% and 75%. Extreme environmental conditions can impact print quality and printer longevity.

3. Regular Firmware Updates: Check for and install firmware updates regularly to ensure your printer has the latest features and bug fixes.

Additional Maintenance Tips

1. Prevent Dust Buildup: Regularly clean the printer's exterior to prevent dust buildup, which can affect its ventilation and overall performance.

2. Inspect for Damage: Regularly inspect the printer for any signs of damage, such as loose wires or cracked components. Promptly address any issues to prevent further damage.

3. Seek Professional Assistance: If you encounter any complex maintenance issues or require technical assistance, contact an authorized Kenteer service technician.

By following these comprehensive maintenance recommendations, you can ensure that your KTM-A45 DTF Printercontinues to deliver exceptional print quality and performance for years to come. Regular maintenance is an investment in the longevity and productivity of your printer.

If you have product purchasing needs, you can contact us.