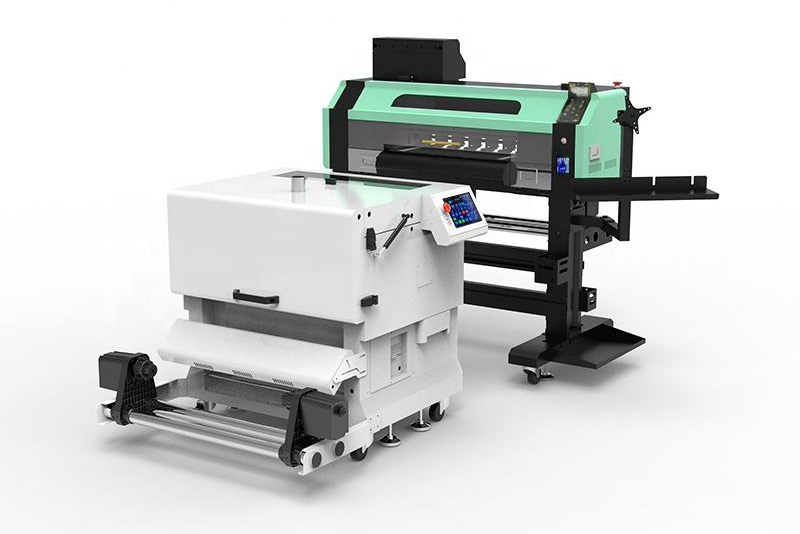

Boost Efficiency with the Kenteer KTM-33400

The KTM-33400 A3 DTF powder applicator from Kenteer is designed for fast, high-quality textile printing. It is built to handle complex production with minimal manual input.

Compact Yet Production-Ready

Supporting media widths up to 380mm, this fabric printing machine works with nylon, cotton, chemical fiber, leather, and more. Its compact body hides serious industrial power.

Smart Powder Application System

The powder control system is highly adjustable. Operators can set direction, flow rate, and timing. This level of control guarantees a consistent powder coat on any fabric.

Controlled Heating and Curing

This automatic heat transfer unit includes a heated guide plate, curing system, and cold air cooling. These features work together to ensure that the transfer film adheres evenly and dries fast.

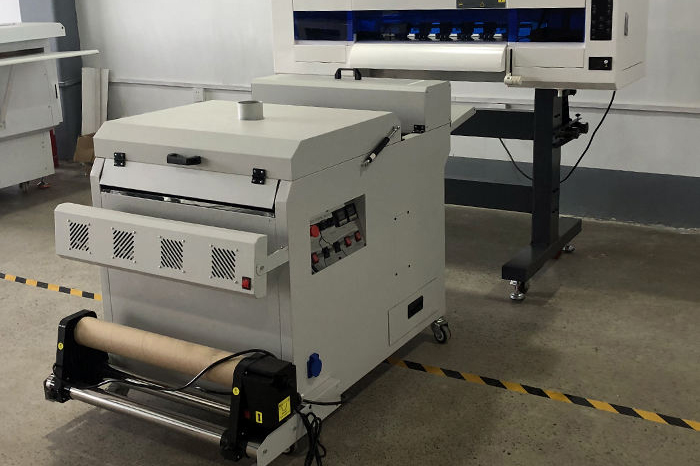

Hands-Free Media Handling

Paper feed and collection are fully automated. The industrial DTF equipment includes a traction system and auto-winding sensor. This reduces the need for operator supervision and helps prevent material misfeeds.

Energy-Smart Operation

The rated power is 2.2KW, with real-world consumption from 1KW to 2.2KW. It runs on 220V and 10A, making it suitable for workshops that demand low energy waste.

Engineered for Mobility

With a footprint of just 1185mm by 608mm and a height of 641mm, it fits tight workspaces. A net weight of 50KG means the unit can be moved or repositioned as needed.

Trusted Kenteer Performance

Kenteer brings decades of printing expertise. The KTM-33400 embodies the brand’s dedication to stable output, smooth operation, and smart controls. It's the right fit for modern fabric producers.

Designed for Production Lines

Perfect for mid-size factories, this fabric printing machine can operate non-stop. Smart sensors reduce operator fatigue while ensuring consistent print quality.

Backed by Professional Support

All Kenteer machines come with full training and technical guidance. The KTM-33400 is no exception. Buyers gain a high-performance unit and peace of mind with every order.