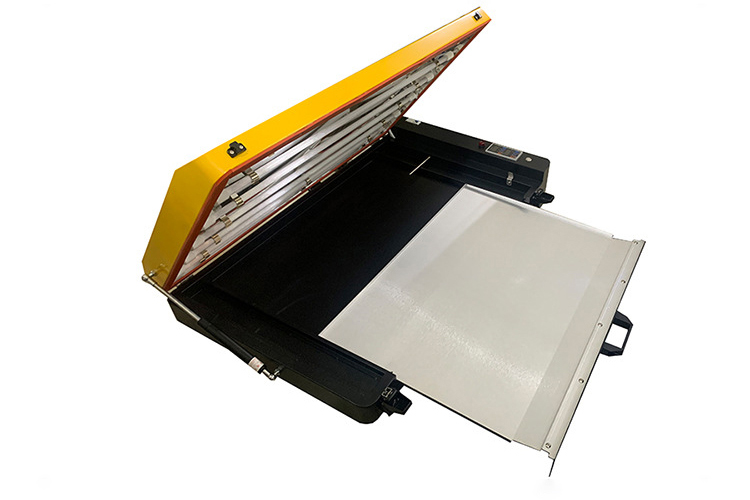

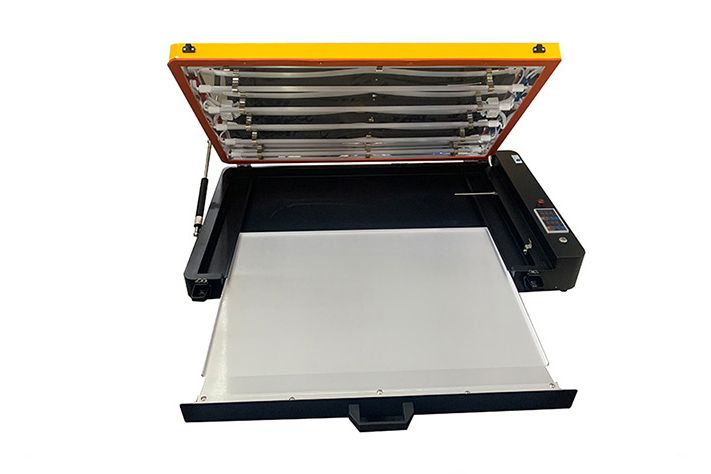

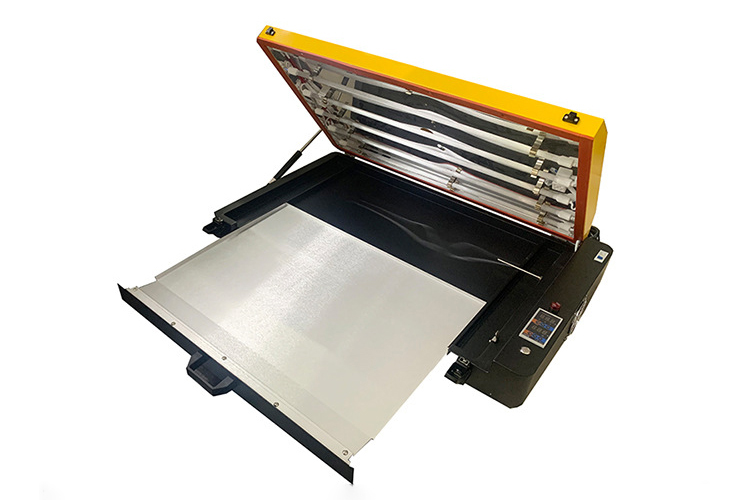

The DTF Oven plays a crucial role in the Direct-to-Film printing process, contributing to the transfer of vibrant designs onto various garments and materials. To ensure the oven's optimal performance and longevity, regular maintenance is essential. Here are comprehensive maintenance recommendations for the DTF Oven:

1. Routine Cleaning

Keep the oven's interior clean to prevent the accumulation of dust, debris, and ink residue. Regular cleaning will maintain the oven's efficiency and prevent potential malfunctions.

Utilize a soft cloth dampened with a mild detergent or isopropyl alcohol to wipe the interior surfaces. Avoid using harsh chemicals or abrasive materials that may damage the oven's components.

Ensure the oven is thoroughly dry before resuming operation to prevent electrical hazards.

2. Temperature Calibration

Periodically calibrate the oven's temperature settings to ensure accurate and consistent heating. Temperature fluctuations can compromise the quality of the transferred prints.

Consult the manufacturer's guidelines for the recommended calibration procedure. Specialized equipment like a temperature probe or infrared thermometer may be required.

Adjust the temperature settings accordingly to match the desired heating levels specified for the DTF film and ink.

3. Conveyor Belt Maintenance

Inspect the conveyor belt regularly for signs of wear, damage, or misalignment. A worn or damaged belt can affect the smooth movement of the printed film, leading to printing errors.

Clean the conveyor belt using a soft cloth and a mild detergent. Avoid using harsh chemicals or abrasive materials that may damage the belt's surface.

Ensure the conveyor belt is properly aligned and tensioned according to the manufacturer's instructions. Improper alignment or tension can cause the belt to slip or move erratically.

4. Heating Element Maintenance

Regularly inspect the heating element for signs of damage, corrosion, or loose connections. A faulty heating element can result in uneven heating or complete failure of the oven.

Clean the heating element using a soft brush to remove dust and debris. Avoid touching the heating element while it is in operation or immediately after use due to high temperatures.

Ensure the heating element is securely fastened and all electrical connections are tight. Loose connections can cause arcing or overheating, posing safety hazards.

5. Electrical Maintenance

Inspect the oven's electrical components, including wires, plugs, and switches, for signs of damage, loose connections, or exposed wires. Electrical faults can lead to malfunctions, safety hazards, or even fire.

Ensure the oven is properly grounded to prevent electrical shocks. Grounding provides a safe path for electrical current to flow in case of a fault.

Have a qualified electrician perform regular electrical inspections and maintenance to ensure the oven's continued safe operation.

6. Preventative Measures

Always follow the manufacturer's instructions for operating and maintaining the DTF Oven. Adhering to the specified guidelines will help prevent unnecessary wear and tear.

Store the oven in a clean, dry environment when not in use. Exposure to excessive moisture, dust, or direct sunlight can shorten the oven's lifespan.

Avoid overloading the oven with excessive prints or materials. Overloading can strain the oven's components and compromise its performance.

Perform regular visual inspections of the oven's overall condition. Promptly address any abnormalities or potential issues to prevent more severe problems.

By implementing these maintenance recommendations, you can extend the lifespan of your DTF Oven, ensure consistent high-quality prints, and minimize the risk of downtime or malfunctions. Regular maintenance will keep your DTF Oven operating at its best, enabling you to produce vibrant and durable prints for your customers.

Kenteer supplies DTF Oven. Customers in need are welcome to contact us.