In the realm of large format printing, choosing the right printing material is crucial to achieving high-quality results. Among the popular options available, PET film A3 and DTF film A3 have emerged as contenders, each with its own unique characteristics and advantages. In this article, we delve into the key differences between PET film A3 and DTF film A3, shedding light on their applications and helping you make an informed choice for your printing needs.

PET Film A3

PET film A3, also known as Polyethylene Terephthalate film, is a transparent plastic material widely used in various printing applications. It offers excellent clarity and durability, making it a popular choice for posters, signage, and graphic overlays. PET film A3 can be printed using a range of techniques, including inkjet and laser printing.

PET Film A3 Printing Process and Techniques

PET film A3 is compatible with inkjet and laser printing methods. Inkjet printing on PET film A3 provides vibrant colors and detailed prints, making it suitable for various applications. Laser printing, on the other hand, offers sharp and precise results, making it ideal for text and vector graphics.

Key Features and Advantages

PET film A3 offers several key features and advantages. Firstly, it provides exceptional clarity, ensuring that the printed content is sharp and easily visible. Secondly, PET film A3 is highly durable and resistant to tearing and moisture, making it suitable for both indoor and outdoor applications. Additionally, it offers excellent compatibility with different printing techniques and adheres well to a wide range of substrates.

Applications and Usage Scenarios

PET film A3 finds applications in diverse printing projects. It is commonly used for creating posters, point-of-sale displays, window graphics, and graphic overlays. Its durability makes it suitable for outdoor signage, where resistance to weather conditions is essential. PET film A3 is also utilized in industries such as retail, hospitality, and advertising.

Limitations and Considerations

While PET film A3 has many advantages, it is important to consider certain limitations. PET film A3 may not offer the same level of color vibrancy and accuracy as some other printing materials. Additionally, it may not be the best choice for applications that require complex and intricate designs. Care should also be taken to avoid excessive heat during printing, as PET film A3 can warp under high temperatures.

DTF Film A3

DTF film A3, which stands for Direct-to-Film film, is a revolutionary printing material that has gained attention in recent years. Unlike traditional printing methods, DTF involves transferring ink directly from a special film onto the desired substrate. DTF film A3 offers vibrant colors and excellent adhesion on a variety of surfaces, making it suitable for apparel printing, customized merchandising, and more.

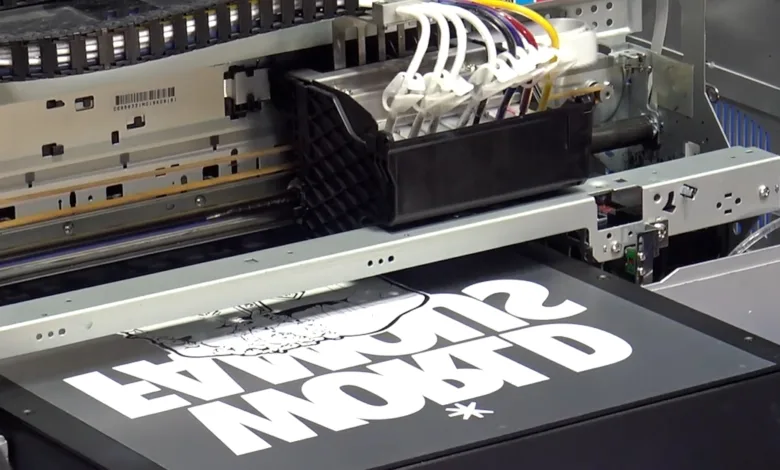

Printing Process and Techniques

DTF film A3 utilizes a unique direct-to-film transfer process. The printing is done on a specialized film, which is then transferred directly onto the desired substrate using heat and pressure. This process allows for vibrant colors, intricate details, and excellent adhesion on fabrics and other materials.

Key Features and Advantages

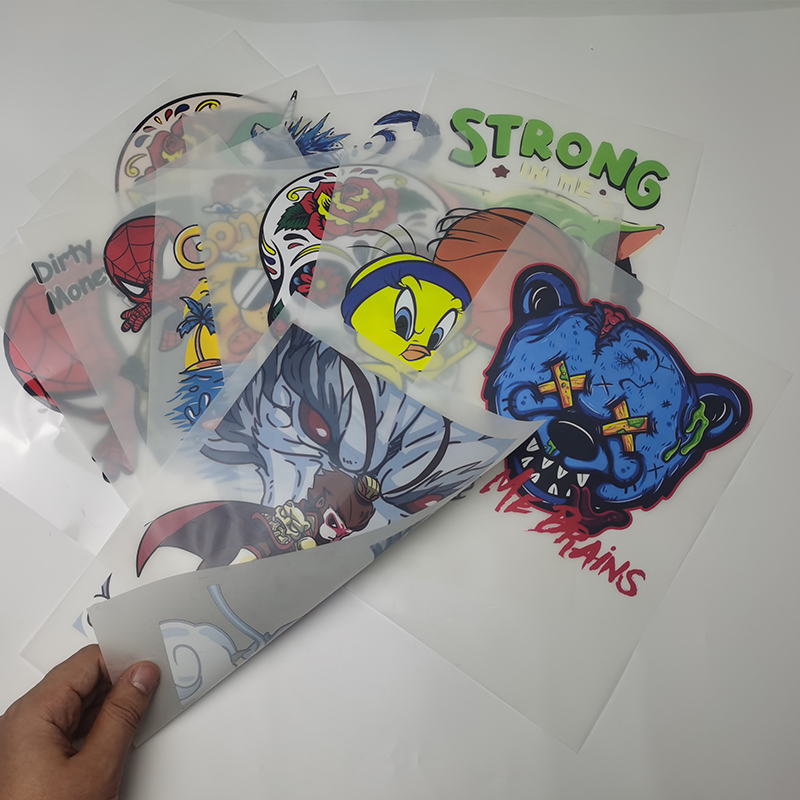

DTF film A3 offers several key features and advantages. The direct-to-film transfer method ensures vibrant and vivid colors, resulting in eye-catching prints. It allows for intricate and detailed designs, making it ideal for apparel printing and customized merchandise. DTF film A3 also offers good adhesion on a variety of surfaces, providing durability and washability for fabric prints.

Applications and Usage Scenarios

DTF film A3 finds applications in various printing projects, particularly in the apparel industry. It is commonly used for creating custom t-shirts, hoodies, hats, and other fabric-based products. DTF film A3 allows for printing vibrant and detailed designs directly onto the fabric, offering customization options for individuals, businesses, and promotional events. It is also suitable for creating personalized merchandise, such as bags, accessories, and promotional items.

Limitations and Considerations

While DTF film A3 offers many advantages, it is important to consider certain limitations. The direct-to-film transfer process may require specialized equipment and consumables, which can increase the initial setup cost. Additionally, DTF film A3 may not be as widely available as PET film A3, limiting its accessibility in some regions. It is essential to ensure proper heat pressing and curing processes to achieve long-lasting and durable prints.

Comparing Print Quality and Resolution

When it comes to print quality and resolution, both PET film A3 and DTF film A3 deliver impressive results. PET film A3 offers exceptional clarity and sharpness, particularly in text and vector graphics. On the other hand, DTF film A3 boasts vibrant colors and a wide color gamut, making it ideal for detai

led and intricate designs. Both options provide high-resolution prints, but the choice depends on the specific requirements of the project.

Durability and Longevity

PET film A3 is known for its excellent durability and resistance to tearing and moisture. It can withstand harsh environments and is suitable for both indoor and outdoor applications. DTF film A3, while relatively new to the market, has also shown promise in terms of durability. However, it may require additional steps, such as heat pressing and proper curing, to ensure long-lasting results. It is crucial to follow recommended care instructions for fabric prints created with DTF film A3 to maintain their longevity.

Color Vibrancy and Accuracy

In terms of color vibrancy, DTF film A3 has an edge over PET film A3. The direct ink transfer process of DTF allows for vibrant and vivid colors, resulting in eye-catching prints. PET film A3, though offering good color reproduction, may not match the same level of vibrancy as DTF film A3. However, it's important to note that the perceived color accuracy can also be influenced by the printing equipment, ink quality, and calibration.

Versatility and Compatibility

PET film A3 is compatible with various printing techniques, including inkjet and laser printing. It adheres well to a wide range of substrates, making it suitable for diverse applications. It is commonly used in graphic arts, advertising, and retail industries. DTF film A3, with its unique direct-to-film transfer method, is specifically designed for fabric and apparel printing, providing excellent adhesion and flexibility. It is most commonly utilized in the apparel industry for customized designs and promotional merchandise.

Cost-effectiveness and Efficiency

PET film A3 is generally more cost-effective than DTF film A3, as it is a widely available and established printing material. It is a reliable choice for bulk printing projects and applications where cost plays a significant role. The equipment and consumables required for DTF printing may have higher initial costs. However, DTF film A3 offers efficiency in terms of customization and quick turnaround time, especially for small print runs or personalized designs.

Conclusion

In conclusion, both PET film A3 and DTF film A3 have their own strengths and applications in the realm of large format printing. PET film A3 excels in durability, versatility, and compatibility with various printing techniques. It is a reliable choice for applications such as signage, posters, and graphic overlays. DTF film A3, on the other hand, offers vibrant colors, excellent adhesion on fabrics, and customization options, making it ideal for apparel printing and personalized merchandise.