In the world of heat transfers, advancements in technology have opened up new avenues for creativity and efficiency. One such innovation is DTF (Direct-to-Film) film, a revolutionary method that offers distinct advantages over traditional heat transfer techniques like screen printing and vinyl cutting. In this article, we will explore the numerous benefits of using DTF film for heat transfers, highlighting its versatility, durability, and cost-effectiveness. As we delve into the advantages, we will also spotlight how Kenteer, a leading brand in the printing industry, utilizes DTF film to empower businesses and elevate their printing projects.

Understanding DTF Film

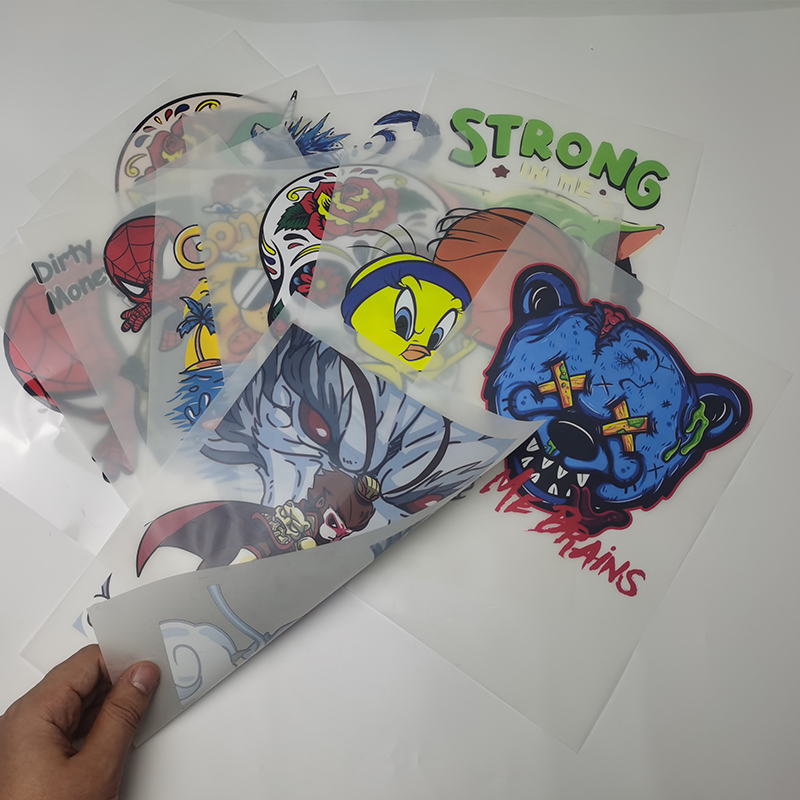

DTF film is a specialized heat transfer material that consists of a thin, transparent film layer coated with a release adhesive layer and a printable surface.

The film is compatible with various ink types, including eco-solvent, solvent, and pigment inks.

How DTF Film Differs from Traditional Methods

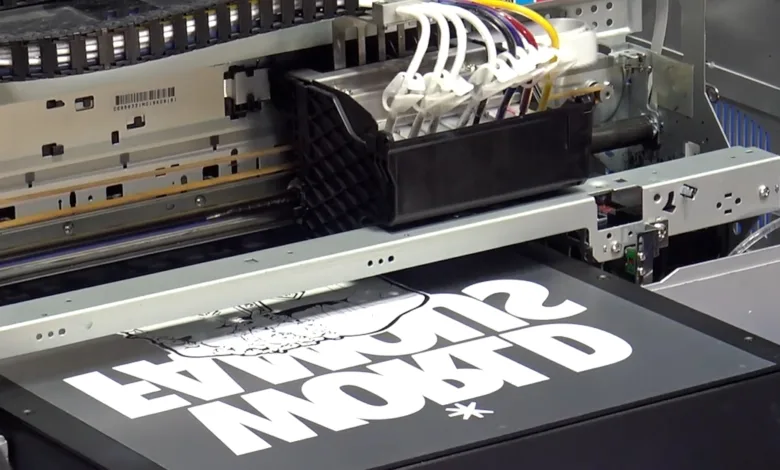

Unlike screen printing, which involves creating stencils and using squeegees to transfer ink onto substrates, DTF film transfers designs directly from a printed film to the target surface.

In comparison to vinyl cutting, where designs are cut out of colored vinyl sheets, DTF film allows for full-color printing, including vibrant gradients and intricate details.

Advantages of DTF Film for Heat Transfers

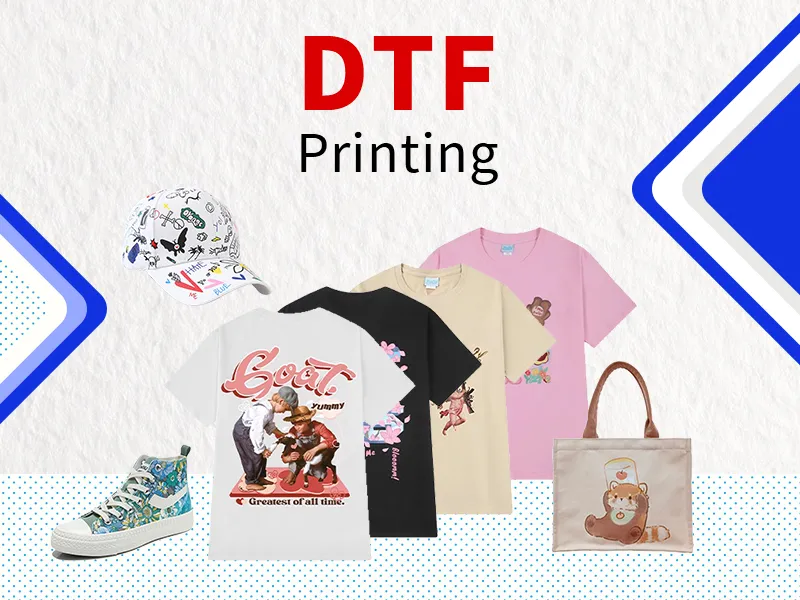

Versatility in Printing: DTF film can be used on a wide range of fabrics, including cotton, polyester, blends, and even non-textile materials like ceramics and leather. It enables printing on light and dark-colored garments, offering flexibility for diverse design requirements.

Full-Color and High-Resolution Prints: DTF film allows for photorealistic and full-color prints, ensuring vibrant and detailed designs. It surpasses the limitations of traditional methods, such as screen printing, which may have color restrictions or limited resolution.

Enhanced Durability and Washability: DTF film transfers exhibit excellent durability, with prints that can withstand numerous wash cycles without fading or cracking. The film's adhesive layer creates a strong bond with the fabric, ensuring long-lasting and vibrant designs.

Greater Design Detail and Complexity: DTF film enables the printing of intricate designs, fine lines, small text, and complex graphics with exceptional precision. It opens up new creative possibilities, allowing businesses to produce customized products that stand out in the market.

Cost-Effectiveness and Efficiency: Compared to screen printing, DTF film eliminates the need for costly screens and setup time.

It offers a streamlined process, allowing for quick and efficient printing, particularly for small to medium-sized production runs.

Easy Application and Curing Process: DTF film transfers are user-friendly and require minimal equipment, making them accessible to businesses of all sizes. The curing process is straightforward, involving heat pressing the film onto the fabric to achieve a permanent bond.

Eco-Friendly Printing Solution: DTF film uses water-based inks, which are more environmentally friendly compared to solvent-based alternatives. It reduces the generation of hazardous waste typically associated with screen printing or vinyl cutting.

Kenteer: Empowering Businesses with DTF Film Technology

Cutting-Edge DTF Film Solutions

Kenteer, a renowned brand in the printing industry, offers a comprehensive range of high-quality DTF film products designed for various applications. Their DTF films are engineered to deliver exceptional print quality, durability, and versatility, ensuring customer satisfaction.

Customization and Brand Enhancement

Kenteer understands the importance of brand identity and offers customizable DTF film solutions to align with each client's unique requirements.

Through personalized printing options, businesses can elevate their brand presence and create captivating designs that resonate with their target audience.

Expert Support and Guidance

Kenteer provides professional support and guidance to businesses venturing into DTF film printing.

Their team of experts offers technical assistance, troubleshooting, and best practices to ensure smooth operations and optimal print results.

Commitment to Quality and Reliability

Kenteer is dedicated to delivering top-notch DTF film products that meet rigorous quality standards.

Their commitment to reliability ensures consistent performance, vibrant prints, and durable transfers, building trust with their clients.

Competitive Pricing and Cost Savings

Kenteer understands the value of cost-effectiveness and offers competitive pricing for its DTF film products.

By providing affordable solutions, they enable businesses to maximize their return on investment and enhance their profitability.

Harnessing the Power of DTF Film for Business Success

Expanding Product Offerings: Businesses can leverage DTF film technology to expand their product offerings and cater to diverse customer demands. From personalized apparel and promotional items to home decor and accessories, the possibilities for creative applications are endless.

Tapping into Niche Markets: DTF film printing enables businesses to tap into niche markets by offering unique and customized products. With the ability to print on a wide range of materials, including ceramics and leather, businesses can explore specialized applications and stand out in their respective industries.

Strengthening Brand Loyalty: Utilizing DTF film to create high-quality, durable, and visually appealing products enhances brand loyalty among customers. The ability to produce customized designs that reflect individual preferences or brand aesthetics fosters a deeper connection and fosters repeat business.

Embracing Sustainability: DTF film's eco-friendly nature aligns with growing consumer concerns about environmental sustainability. By adopting DTF film printing, businesses can position themselves as environmentally responsible and appeal to eco-conscious consumers.

In the ever-evolving world of heat transfers, DTF film has emerged as a game-changing technology, revolutionizing the way businesses approach printing. The advantages it offers over traditional methods, such as screen printing and vinyl cutting, make it an appealing choice for businesses seeking versatility, durability, and cost-effectiveness. Kenteer, a trusted brand in the industry, empowers businesses by providing high-quality DTF film solutions, customization options, expert support, and a commitment to excellence. By harnessing the power of DTF film, businesses can unlock new printing possibilities, expand their product offerings, strengthen their brand, and propel their success in the market. With Kenteer and DTF film technology, businesses can embark on a transformative printing journey that elevates their brand identity and captures the hearts of their target audience.