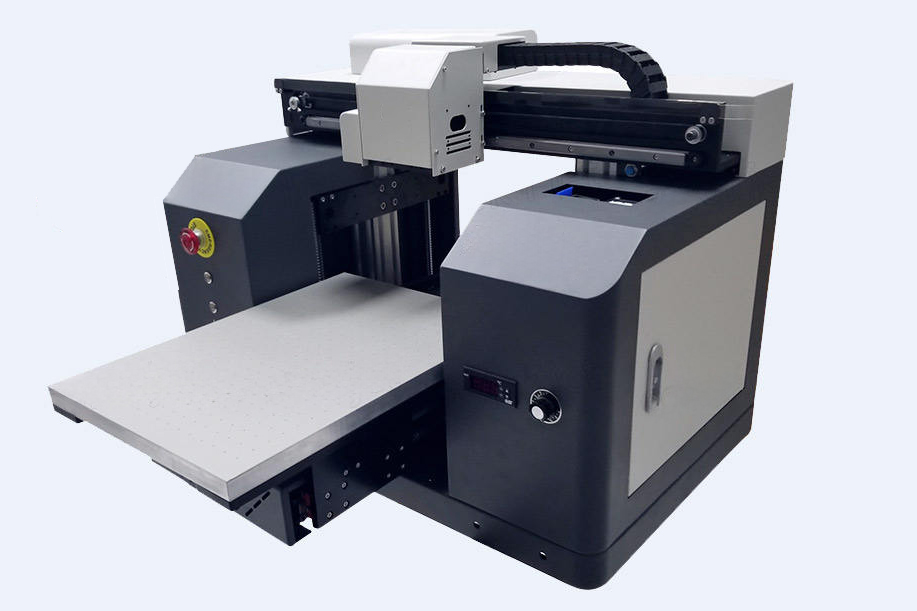

The KTM-A05 A3 UV Flatbed Printer is a versatile machine capable of producing high-quality prints on a wide range of materials. To ensure it continues to deliver exceptional results, regular maintenance is crucial. This guide provides essential recommendations for keeping your KTM-A05 in top condition, maximizing its lifespan and print quality.

Understanding the KTM-A05's Components

Before diving into maintenance procedures, let's familiarize ourselves with the KTM-A05's key components:

Control Panel: The control panel allows you to operate the printer, initiate printing jobs, and monitor settings.

Limit Sensor: This sensor automatically detects the height of the printing material, ensuring proper print head positioning.

Railway: The high-quality steel guide rail ensures smooth and precise movement of the print head carriage.

Missing Ink Alarm Light: This light illuminates when an ink cartridge is empty, prompting you to replace it.

Platform Lift Button & Emergency Stop Button: These buttons control the movement and emergency stop of the printing platform.

Platform Suction Button, Temperature Button & Powder Adjustment Button: These buttons manage the platform's suction functionality, printing temperature, and white ink density.

Recommended Maintenance Practices

Here's a breakdown of recommended maintenance practices for your KTM-A0 A3 UV Flatbed Printer :

1. Daily Maintenance:

Cleaning the Print Head: Regularly clean the print head with a lint-free cloth dampened with appropriate cleaning solution (consult your user manual for recommended cleaning solutions). This removes dried ink particles that can affect print quality.

Cleaning the Platform: Wipe down the printing platform with a soft cloth after each use. Remove any dust, debris, or cured ink residue that might interfere with subsequent prints.

Emptying the Waste Ink Tank: Regularly empty the waste ink tank according to the manufacturer's instructions. Overflowing the waste tank can damage the printer.

2. Weekly Maintenance:

Cleaning the Cap and Wiper: The capping station houses the print head when not in operation and the wiper cleans the head during printing. Routinely clean these components with a lint-free cloth and appropriate cleaning solution to prevent ink buildup.

Lubrication: Apply a light coat of lubricant (recommended by the manufacturer) to the guide rails to maintain smooth movement of the print head carriage.

3. Monthly Maintenance:

Deep Cleaning the Print Head: Perform a more thorough cleaning of the print head using a cleaning kit specifically designed for UV printers. This removes stubborn ink deposits that might not be eliminated by daily cleaning.

Inspecting the Limit Sensor: Ensure the limit sensor is free of dust or debris and functioning properly. A faulty sensor can lead to incorrect print head positioning and potential print errors.

4. Additional Maintenance Tips:

Maintain Proper Ink Levels: Regularly monitor ink levels and replace cartridges before they run out. Using low ink can result in streaky or faded prints.

Use High-Quality Ink: Invest in high-quality UV ink specifically formulated for your printer model. Substandard ink can clog the print head and compromise print quality.

Maintain Optimal Printing Environment: The KTM-A05 operates best in an environment with a temperature between 0°C and 30°C and humidity between 40% and 70%. Extreme temperatures or humidity levels can negatively impact print quality.

Calibrating the Print Head: Regularly calibrate the print head to ensure accurate ink placement and optimal print resolution. Refer to your user manual for calibration instructions.

Keeping the User Manual Handy: The user manual provides valuable information on troubleshooting common issues, performing maintenance procedures, and replacing parts. Keep it easily accessible for reference.

By following these recommendations, you can ensure your KTM-A05 A3 UV Flatbed Printer operates smoothly and delivers exceptional prints for years to come. Remember, preventative maintenance is key to extending the lifespan of your printer and achieving optimal printing results.

If you have product purchasing needs, you can contact us.