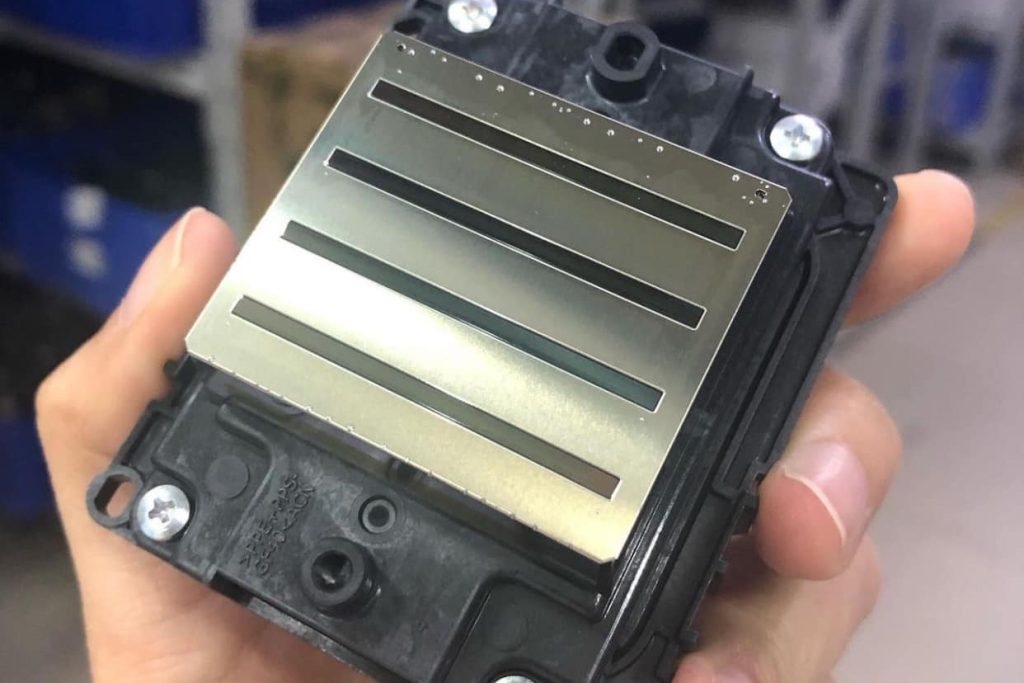

In the realm of industrial printing, printheads play a pivotal role in determining print quality, productivity, and operational costs. As a leading manufacturer of industrial inkjet printing technology, Epson has introduced the I3200(8)-A1HD printhead, an advanced solution that offers significant advantages in terms of replacement costs when compared to conventional printheads.

Understanding the Cost Factors of Printheads

Printers are complex systems that require regular maintenance and component replacement. Printheads, being the core component responsible for ejecting ink droplets onto the substrate, are subject to wear and tear over time. The replacement cost of printheads is a major factor that contributes to the overall operational expenses of an industrial printing system.

Conventional printheads typically have a limited lifespan, requiring replacement after a certain number of printing cycles or hours of operation. This can result in significant downtime and associated costs, including the cost of the replacement printhead itself, labor for installation, and potential production losses.

Introducing the I3200(8)-A1HD: Enhanced Durability, Reduced Costs

The Epson I3200(8)-A1HD printhead is designed to address the issue of high replacement costs by offering exceptional durability and longevity. Through its innovative design and advanced materials, this printhead boasts an extended lifespan that significantly reduces the frequency of replacement.

Key Features Contributing to Reduced Replacement Costs:

- Robust Piezoelectric Element: The I3200(8)-A1HD printhead features a highly durable piezoelectric element that has been tested to withstand over 1060 billion actuations, ensuring consistent performance over an extended period of time.

- Enhanced Pressure Resistance: The printhead can withstand repetitive cleaning at pressures up to 40KPa, making it less susceptible to damage from the harsh cleaning processes often required in industrial printing environments.

How the I3200(8)-A1HD Reduces Replacement Costs in Practice

The extended lifespan of the I3200(8)-A1HD printhead directly translates into reduced replacement costs for businesses. By significantly increasing the interval between replacements, the need for purchasing new printheads and incurring related labor expenses is drastically minimized.

For example, consider a typical industrial printing operation that uses conventional printheads with a lifespan of 5,000 hours. Assuming an average replacement cost of $500 per printhead, the total replacement cost over a 5-year period would be approximately $50,000.

In contrast, the I3200(8)-A1HD printhead with its extended lifespan of over 10,000 hours would require replacement only half as often, resulting in a total replacement cost of just $25,000 over the same 5-year period. This represents a substantial savings of $25,000, or a 50% reduction in printhead replacement costs.

The Epson I3200(8)-A1HD printhead offers a compelling solution for businesses looking to minimize printhead replacement costs and maximize operational efficiency. Its exceptional durability and longevity significantly reduce the frequency of replacement, leading to substantial savings over the life of the printing system. By investing in the I3200(8)-A1HD printhead, businesses can enjoy lower operating expenses and greater profitability over the long term.

The above is the printer nozzle information provided by Kenteer. If you need to purchase printer equipment, you can contact us.