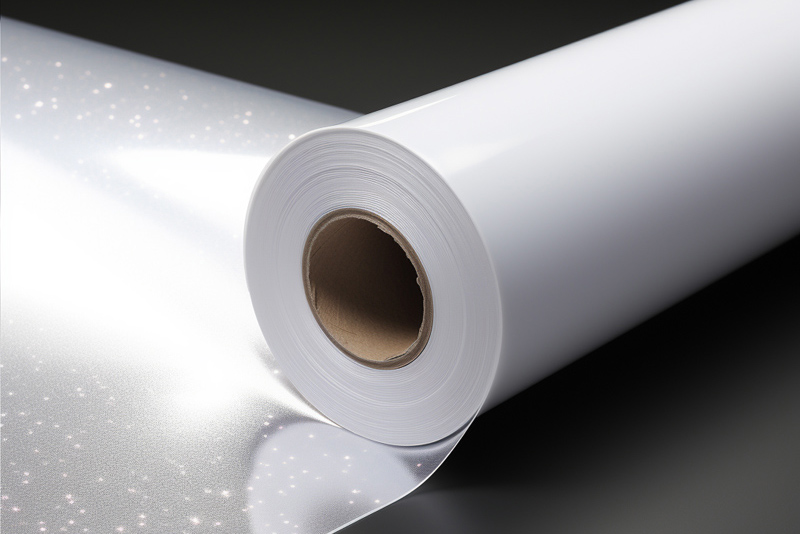

The glitter DTF film production industry is on the cusp of transformation as it embraces innovative manufacturing technologies. These advancements are set to revolutionize the way glitter DTF film is produced, opening up new possibilities, improving efficiency, and enhancing product quality. In this article, we explore how innovation in manufacturing technologies is shaping the future of glitter DTF film production.

1. Digital Printing Technologies:

The adoption of advanced digital printing technologies is a game-changer for glitter DTF film production. High-resolution digital printers enable precise and vibrant glitter applications, offering designers and manufacturers unparalleled creative freedom. This technology allows for intricate patterns, designs, and color gradients, enhancing the visual appeal of glitter DTF films.

2. Automation and Robotics:

Automation and robotics are being integrated into glitter DTF film production lines. Automated machinery can handle repetitive tasks with speed and accuracy, reducing manual labor and the risk of errors. Robotics can assist in tasks such as material handling, quality control, and packaging, resulting in improved efficiency and product consistency.

3. Smart Manufacturing and Industry 4.0:

Glitter DTF film production is increasingly embracing smart manufacturing principles and Industry 4.0 concepts. Internet of Things (IoT) sensors and data analytics provide real-time monitoring of production processes, ensuring quality control and process optimization. Predictive maintenance using AI algorithms minimizes downtime and maximizes efficiency.

4. Sustainable Materials and Processes:

Innovations in manufacturing technologies are enabling the use of sustainable materials and eco-friendly processes in glitter DTF film production. Water-based inks and biodegradable glitter particles are being integrated, aligning with the growing demand for environmentally responsible products.

5. Nanotechnology and Coatings:

Nanotechnology is being harnessed to develop specialized coatings and finishes for glitter DTF films. Nanoparticles can enhance the film's durability, UV resistance, and adhesive properties. These coatings improve the overall performance and longevity of glitter DTF films.

6. Material Science Advancements:

Research in material science is leading to the development of novel glitter DTF film substrates and glitter particles. These innovations result in films that are lighter, more flexible, and offer enhanced optical properties, providing designers with greater creative possibilities.

7. Rapid Prototyping:

Manufacturers are leveraging rapid prototyping techniques to quickly test and iterate new glitter DTF film designs. This expedites the development process, allowing for faster product launches and customization options for clients.

8. Customization on Demand:

Advancements in digital printing technologies and software enable customization on demand. Manufacturers can offer clients the ability to create bespoke glitter DTF films with specific colors, patterns, and effects in real-time, meeting individualized design needs.

9. Global Connectivity and Supply Chain Optimization:

Manufacturers are optimizing their supply chains using digital technologies and global connectivity. This streamlines the sourcing of materials, production, and distribution, ensuring a seamless and efficient operation.

The future of glitter DTF film production is bright and dynamic, driven by innovation in manufacturing technologies. Digital printing, automation, smart manufacturing, sustainability, nanotechnology, 3D printing, material science advancements, rapid prototyping, customization, and supply chain optimization are reshaping the industry. These innovations empower manufacturers to create high-quality glitter DTF films that cater to diverse design preferences, offer sustainability options, and maintain efficiency in production processes. As these technologies continue to evolve, we can expect glitter DTF films to become even more versatile and exciting, inspiring designers and businesses to explore new creative horizons.

As a professional dtf glitter film rolls manufacturer in China, Kenteer looks forward to your cooperation.