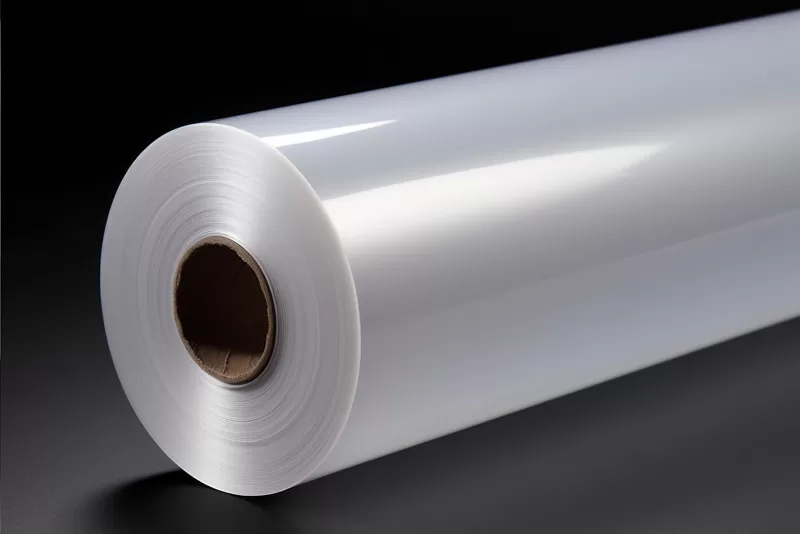

UV DTF film, incorporating the use of ultraviolet (UV) curing technology, has gained significant popularity in the printing industry. Its fast curing properties, excellent drying capabilities, durability, vibrant color reproduction, and wide range of applications make it a preferred choice for various printing needs. This article will delve into the extensive applications and advantages of UV DTF film, shedding light on its versatility and the benefits it offers to the printing industry.

- UV DTF Film: An Overview:

- UV DTF film utilizes UV curing technology to rapidly solidify ink or coatings, reducing waiting time and enhancing printing efficiency.

- The film's excellent drying characteristics prevent adhesion, buildup, and potential contamination of the printed material.

- UV-printed inks or coatings exhibit remarkable durability, including resistance to wear, scratches, UV radiation, and chemical corrosion, significantly extending the lifespan of printed products.

- UV printing enables the reproduction of high-saturation colors, resulting in vivid and intricate images.

- Wide Range of Applications:

- UV DTF film finds extensive use on various materials such as paper, plastic, metal, leather, glass, ceramics, and more, making it highly versatile.

- It is particularly suitable for decorative applications on rigid materials, allowing for creative designs on diverse surfaces.

- The film's adaptability makes it valuable in industries like fashion, textiles, signage, packaging, advertising, and personalized merchandise.

- Technical Specifications:

- A-film: Composed of PET, available in thicknesses ranging from 75-120um.

- A-film variations: White backing made from coated paper, with thicknesses between 170-190gsm.

- B-film: Manufactured using polypropylene (PP) and ranges in thickness from 75-95um.

- Packaging options include rolls (62cm, 31cm) and sheets (A3), with different quantities per pack.

- Key Considerations:

- UV DTF film requires the use of UV printing machines and UV inks specifically formulated for this technology.

- The film is designed with easy-to-tear edges for convenient removal of the protective layer before printing (sheets), while roll-to-roll machines offer automated film tearing.

- Different printing effects can be achieved, such as matte (without gloss oil) or glossy (with gloss oil), allowing for versatile output.

- For optimal performance, UV DTF film is recommended for use with a range of complementary UV inks, including CMYK, white ink, and gloss varnish.

- Roll-to-roll machines are recommended for efficient and easy maintenance, while sheet-fed printers require an additional laminating machine (64cm) for B-film application.

- The reinforced B-film reduces the risk of breakage, prevents bubble formation during lamination, and ensures precise transfer and dimensional accuracy of printed labels.

- The film is available in predetermined sizes, with limitations imposed by 30/60cm dimensions. The addition of easy-tear edges increases the width by 1cm in roll packaging, while the length remains unchanged.

Conclusion:

UV DTF film, with its remarkable features and versatility, has revolutionized the printing industry. Its ability to provide fast curing, excellent drying, durability, vibrant colors, and wide-ranging applications has made it an indispensable choice for various printing needs. Whether used in fashion, textiles, advertising, or personalized merchandise, UV DTF film continues to enhance printing possibilities and deliver outstanding results.

kenteer specializes in the production and wholesale of UV DTF Film. If you have production and wholesale needs, you can contact us.